David1975;14357495 said:

OK NI200 wire.

First, lets dispel the NR myth, there is NO SUCH THING as Non-resistance wire! ALL wire has resistance, even so called super-conductors cooled by liquid nitrogen have resistance. How much resistance is a property of the various materials. NI200 has a very very low resistance when compared to Kanthal.

- 30g Kanthal = 8.36Ω per foot

- 30g Titanium = 5.9Ω per foot

- 30g NI200 = 0.6Ω per foot

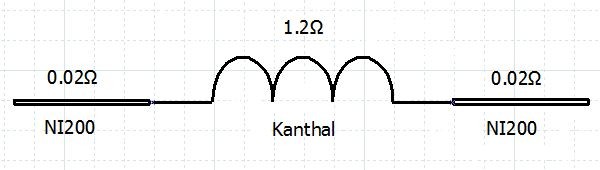

The "NR" nickname was erroneously coined (I think by Imeo) when attys like the Ithika first came out that needed legs that didnt get as hot as the coil itself. So they used very low resistance wire for the legs, and higher resistance wire for the coil. They used coils something like this, which is akin to three resistors in series:

(Evolv speculates that you make this same so called NR/R setup using something like 28g NI200 for the legs and 36g Ni200 for the coil.)

Now a higher resistive material (like Kanthal) will drop more voltage than a lower resistive material, and consequently get much hotter. In this example 96.7% of the voltage was actually being consumed by the Kanthal coil, and only 3.3% by the NI200. Consequently the Kanthal got significantly hotter, and the NI200 stayed significantly cooler.

Now, make the entire thing, coil and legs, out of NI200 and it now represents 100% of the total resistive load and will get very hot, although it takes more current to do it.

Here is a coil of NI200, 12 wraps of 30g Ni200 around a #53 drill bit and it measured 0.12Ω. It is a vertical micro coil in a Taifun that I then packed Lyocell around the outside of the coil, like a carto on steroids.

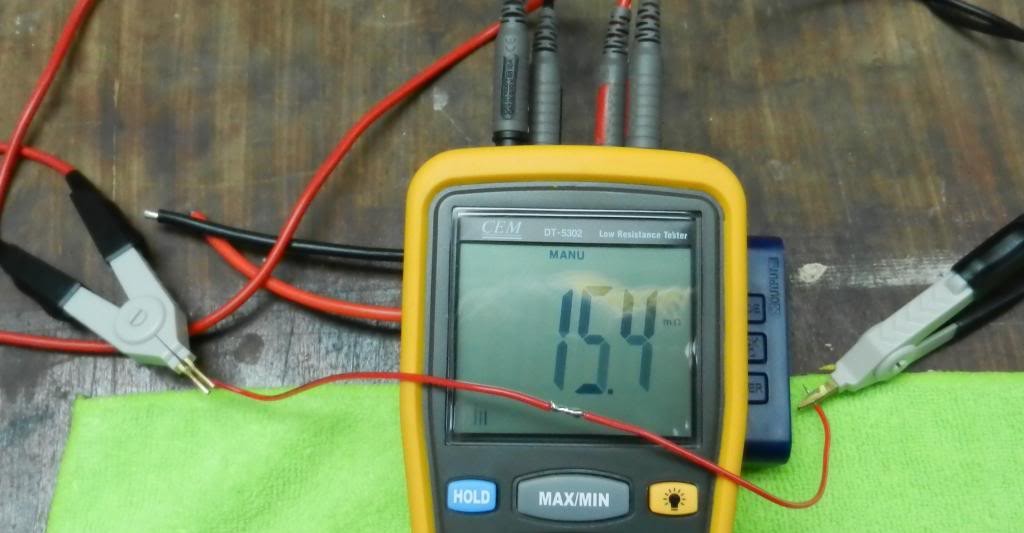

Also note that a standard atty resistance checker worked for it. Most standard multimeters wont read a resistance this low because the meter leads have more resistance than what you are trying to measure. You need what is called a Kelvin meter (it has 4 leads) to read it.

I have a cheap one, but these things get REAL expensive real fast. Here it is where I am testing the resistance of a solder joint, 0.0154 ohms (15.4 milliohms).

All of this being said, the actual resistance is not as big of a deal as it used to be. Sure it has some effect, but the Temp Limiting will keep it from overheating regardless of the resistance (as long as it is NI200 wire), and regardless of the number of wraps etc.

Evolv says that Titanium wire would work with this board too, but you would have to cut your temperature setpoints in half. Ie set it 210 degrees if you wanted 420 degrees. It would be far less accurate, but it would work. They chose NI200 because it's temperature coefficient table was more favorable to accurate measurements.

©2017 Mike Petro. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

How do we measure resistance when making a coil? I understand the board may read it, but as is, will an Ohm meter or multimeter still work with this or is it simply not that important anymore?

How do we measure resistance when making a coil? I understand the board may read it, but as is, will an Ohm meter or multimeter still work with this or is it simply not that important anymore?