Considering the cost associated with replacing an atomizer or cartomizer with a new unit I wanted to develop something that would be "serviceable" with relative ease and only replace the parts that de-generate with continued use - heating coil and wick.

There are some great links in this forum teaching you how to solder and make a new heating coil and there are some more telling you how to calculate the length vs. resistance of nichrome wire and how it would perform using high or low voltage batteries. Thank you to all those contributors, all your great ideas assisted me in developing this simple method of creating a serviceable and highly "modifiable" (if that is an acceptable English word....) atomizer.

There are similar atomizers / cartomizer designs in this forum but what makes this one quite unique is that you can replace the heating coil and wick with great ease and it doesn't necessitate any specialist soldering techniques.

Basically I wanted to make an atomizer with simple connections where it would be easy to replace the wick and heating coil without having to solder wires onto the nichrome wires. Having experimented with various types of cartridges I also wanted an atomizer (or is it a cartomizer?) that would fill easy, hold at least 20 drops of liquid and vape dry to the last drop.

I have made a few "beta" versions of this atomizing cartridge and gave it to my friends at work. They all like the idea and it works far better than the original atomizers, it cleans easily, lasts longer and replacement cost of a wick and heating coil is a fraction of replacing an atomizer or cartomizer..... Off course making a new wick and coil is also very easy - takes about 3 minutes, so you can produce a years supply of wicks and heating coils in under an hour. I guess if you start considering the cost of replacement atomizers you would most likely be able to produce 20 (or more) wicks and coils for the cost of one atomizer with this method....

I will post pictures and the method of making this cartridge tomorrow.

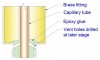

Here is a little apetizer in the mean time.... (fitted onto a Janty Ego battery). It will be possibile to adapt this method to any type PV on the market - whether they use carts or atomizer - I think.....

Happy vaping friends!

There are some great links in this forum teaching you how to solder and make a new heating coil and there are some more telling you how to calculate the length vs. resistance of nichrome wire and how it would perform using high or low voltage batteries. Thank you to all those contributors, all your great ideas assisted me in developing this simple method of creating a serviceable and highly "modifiable" (if that is an acceptable English word....) atomizer.

There are similar atomizers / cartomizer designs in this forum but what makes this one quite unique is that you can replace the heating coil and wick with great ease and it doesn't necessitate any specialist soldering techniques.

Basically I wanted to make an atomizer with simple connections where it would be easy to replace the wick and heating coil without having to solder wires onto the nichrome wires. Having experimented with various types of cartridges I also wanted an atomizer (or is it a cartomizer?) that would fill easy, hold at least 20 drops of liquid and vape dry to the last drop.

I have made a few "beta" versions of this atomizing cartridge and gave it to my friends at work. They all like the idea and it works far better than the original atomizers, it cleans easily, lasts longer and replacement cost of a wick and heating coil is a fraction of replacing an atomizer or cartomizer..... Off course making a new wick and coil is also very easy - takes about 3 minutes, so you can produce a years supply of wicks and heating coils in under an hour. I guess if you start considering the cost of replacement atomizers you would most likely be able to produce 20 (or more) wicks and coils for the cost of one atomizer with this method....

I will post pictures and the method of making this cartridge tomorrow.

Here is a little apetizer in the mean time.... (fitted onto a Janty Ego battery). It will be possibile to adapt this method to any type PV on the market - whether they use carts or atomizer - I think.....

Happy vaping friends!