you could try hardening your SS wire by heating it with a torch to red hot then cooling it in oil and then bake it at 300 degrees for 1/2 hour and letting it air cool after that. depending on the actual material it may or may not work. even hard drawn copper or brass is too soft to make springs out ofSome updates on this. I took everything apart again, polished, cleaned, and reapplied some ox gard to the contact, threads, and both sets of waves in the switch assembly. I put it back together and have been vaping away on it for the last 4 or 5 days. No hot button down to .23 ohms. Still on the original spring. Seems to be hitting nice, not quite as hard as my Stingray or XXIX (Both authentics), but I have no numbers to verify. I did try to build a coil with SS wire, and it didnt really work out well. I also hit WalMart today (and Good Gods Above I hate that place) to see if they had copper wire. They did, but it was to soft to make a useful spring out of, so I passed. I'm going to try and hit Harbor Freight tomorrow to see if I can find that box of assorted springs mentioned previously. Maybe I made a mistake, but is there a trick to making a compression spring? Should I torch the wire?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SMPL Mod (clone) discussion

- Thread starter RandyF

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

you could try hardening your SS wire by heating it with a torch to red hot then cooling it in oil and then bake it at 300 degrees for 1/2 hour and letting it air cool after that. depending on the actual material it may or may not work. even hard drawn copper or brass is too soft to make springs out of

Depends on the mod and the wire.

I have copper springs in my chi you's and kingv1s I made from co-ax cable core.

Should I torch the wire?

I wouldn't even bother with a custom spring at this point, unless you just don't like the throw of the existing one. You have conclusive data that spring conductivity is a non-issue in a properly done mod.

I also hit WalMart today (and Good Gods Above I hate that place)

Walmart is good for plinking ammo and Mobil-1 synthetic.... that is all.

Last edited:

I'm also of the opinion that unless the switch is designed that way (though I can't think why) or you modify it to be so, the spring carries so little current that it's irrelevant. I believe that the main point of conductivity is the point where the button pin passes through the button body. More surface area and a shorter path to the ground. If not then why are magnets and springs are interchangeable?

I also think that unless you have micro-arcing in your threads products like Noalox and the like just gunk things up. If you are going down this road then a dielectric grease like Permatex is your best bet.

A good design and material choice, and being spotlessly clean are the main factors in an efficient mech.

I also think that unless you have micro-arcing in your threads products like Noalox and the like just gunk things up. If you are going down this road then a dielectric grease like Permatex is your best bet.

A good design and material choice, and being spotlessly clean are the main factors in an efficient mech.

Last edited:

I wouldn't even bother with a custom spring at this point, unless you just don't like the throw of the existing one. You have conclusive data that spring conductivity is a non-issue in a properly done mod.

Walmart is good for plinking ammo and Mobil-1 synthetic.... that is all.

A crappy spring will get hot in many switch designs.

It's one of the easiest fixes, and common problems, other than cleaning.

Thanks for the responses guys. The other thing I've noticed is the button assembly, while smooth on threading in, feels a touch loose, which I've read could also be part of the underlying problem. I still don't want to bring either my XXIX or Stingray on vacation with me (even though on my last trip to Jamaica i had no problems through customs, I don't want to risk it) and I don't feel like dealing with a hot button in the middle of the trip, so I think my search for a cheap hard hitting minimalist clone will continue. Bad Ninja speaks highly of the King V2..

I'm obviously going to try replacement springs when having issues as it's as stated such an easy fix to try. Second, Ninja states it can fix hot buttons, and which I trust.

However, we have conflicting opinions though in this thread on the effectiveness of this, theoretically at least, I mean...

Ninja states crappy springs will get hot in some switch designs... By crappy, i'm translating that to high resistance, but maybe i'm wrong(disregarding throw-feel/crunchiness as this is about hot-buttons)...

On the other hand, duc916 states the resistance of the spring is irrelevant as it's in parallel and not the main conductor... If the spring where the main conductor, then I guess it would become hot no matter which nice spring used?

duc916 quotes follows:

Sorry, i'm pretty clueless to this... However, it seems to state that there indeed can be differences between e.g. running 0.2 vs 0.1 builds...

Last thing... In two of my smpl's with screwed-in negative contacts(not c-clip), then those contact pins are pretty small and thin, and so if using very low resistance, then couldn't that be an issue as this is I guess a primary conductor, then dosen't it have to be of lower resistance than my coil to not get hot, or is it only the total resistance of all part together? Sorry if really stupid question... I'm just so confused now, lol... I've tried to read up on it, but quickly it becomes over my head(electrical manuals)...

I'm just so confused now, lol... I've tried to read up on it, but quickly it becomes over my head(electrical manuals)...

@Nikea Tiber and @duc916 , if you could please come with some comments to the above for me/us reading this without great electrical knowledge, then it would be very much appreciated, thanks...

However, we have conflicting opinions though in this thread on the effectiveness of this, theoretically at least, I mean...

Ninja states crappy springs will get hot in some switch designs... By crappy, i'm translating that to high resistance, but maybe i'm wrong(disregarding throw-feel/crunchiness as this is about hot-buttons)...

On the other hand, duc916 states the resistance of the spring is irrelevant as it's in parallel and not the main conductor... If the spring where the main conductor, then I guess it would become hot no matter which nice spring used?

duc916 quotes follows:

Pretty much. A conductive spring would just be a workaround to the problem in your switch, and it won't last for long. Even a 20 ga spring of any material isn't meant to conduct 10-20A of current without overheating it.

Lastly, this quote by Nikea is likewise important:Spring resistance should be irrelevant if the body of the switch is up to snuff. A spring in a switch can be 0.1 ohm or 10000 ohms, it shouldn't matter... as long as the body of the switch is where it should be at .0005 ohms (or something on that extreme order). It doesn't matter what's in parallel with it.

Resistors in parallel (switch and spring) is calculated like this: 1/(Rtotal) = 1/(Rswitch) + 1/(Rspring)

That formula shows overall resistance across the switch will still be roughly .0005 ohms whether your spring conducts a lot or not at all. If the resistance of the switch (Rtotal) starts to creep up to 0.1 or 0.2 ohms, and you have a 0.2 ohm coil in series with it, now it's dropping half your available power and burning your finger.

However it's just very confusing to me, and I still don't get it, sorry... The spring is in parallel to the switch. Can that change so the spring becomes primary conductor if other parts of the switch is dirty. Second, I thought that the spring would get hot if had higher resistance than the coil(which it shouldn't when paralled configured with the other switch-elements ?)...Disassemble your switch, clean every part that makes sliding contact (this is where the current should be passing, if the spring ends up as the path of least resistance, you are going to have a bad time at low atty resistance, because the spring is another heating coil in this situation). When you reassemble, dope all sliding surfaces with a dielectric grease of your choice (tons on the market).

Sorry, i'm pretty clueless to this... However, it seems to state that there indeed can be differences between e.g. running 0.2 vs 0.1 builds...

Last thing... In two of my smpl's with screwed-in negative contacts(not c-clip), then those contact pins are pretty small and thin, and so if using very low resistance, then couldn't that be an issue as this is I guess a primary conductor, then dosen't it have to be of lower resistance than my coil to not get hot, or is it only the total resistance of all part together? Sorry if really stupid question...

@Nikea Tiber and @duc916 , if you could please come with some comments to the above for me/us reading this without great electrical knowledge, then it would be very much appreciated, thanks...

Last edited:

It takes so little to make such a huge difference when you're talking about a 4V electrical circuit. That tiny bit of oxidation you see on your toaster's AC plug is nothing on a 120V circuit. In a 4V/50W circuit, it's like death.

I think the bottom line is, some switches, because they are mechanically tighter and provide a lot more surface area between the button and button housing, are several orders of magnitude better electrically than others (e.g., .001 ohm vs .1 ohm would be two orders better). The resistance through the switch body has to be one or two orders of magnitude better than the spring for the spring to be inconsequential. If your switch body resistance is allowed to creep up to .1 ohm or so then both are going to get hot. Upgrading to super-conductive springs might be a solution in some (inferior) switches, but surface area still sucks where the spring meets the switch, and IMO it's just a workaround to bad design.

Here's an example with some made-up numbers.... let's put a super-conductive .01 ohm spring in a switch that's already .01 ohm. That would give you an improved resistance of .005 ohms.

In a 4V battery with a .2 ohm coil, you're talking a voltage drop of 0.2V without the super-conductive spring; with the upgraded spring it's 0.1V. Would you notice if it hit harder? Maybe, but probably not. Would either of those cause hot button? No. So what happens when you neglect the switch and it creeps up to .1 ohms? Yeah, you have a super-conductive .01 ohm spring that tries to bear the burden, but it's what... 22 gauge? How long can it keep that up? It can't for long, and it shouldn't have to.

I think the bottom line is, some switches, because they are mechanically tighter and provide a lot more surface area between the button and button housing, are several orders of magnitude better electrically than others (e.g., .001 ohm vs .1 ohm would be two orders better). The resistance through the switch body has to be one or two orders of magnitude better than the spring for the spring to be inconsequential. If your switch body resistance is allowed to creep up to .1 ohm or so then both are going to get hot. Upgrading to super-conductive springs might be a solution in some (inferior) switches, but surface area still sucks where the spring meets the switch, and IMO it's just a workaround to bad design.

Here's an example with some made-up numbers.... let's put a super-conductive .01 ohm spring in a switch that's already .01 ohm. That would give you an improved resistance of .005 ohms.

In a 4V battery with a .2 ohm coil, you're talking a voltage drop of 0.2V without the super-conductive spring; with the upgraded spring it's 0.1V. Would you notice if it hit harder? Maybe, but probably not. Would either of those cause hot button? No. So what happens when you neglect the switch and it creeps up to .1 ohms? Yeah, you have a super-conductive .01 ohm spring that tries to bear the burden, but it's what... 22 gauge? How long can it keep that up? It can't for long, and it shouldn't have to.

Last edited:

Thanks alot for that write-up duc!  Very much appreciated! I'll have to read up a bit more on electricity, lol

Very much appreciated! I'll have to read up a bit more on electricity, lol  Thanks again!

Thanks again!

@All

I have bought another toothbrush that is harder than the one before, and although I spend the same time and thoroughness on cleaning as before i.e. about 45 mins just for the alcohol scrubdown per mod, then I think it is helping, atleast for now on one of my smpl's which i've currently tested it with... I think it makes a difference on the 20mm threads... I also use alcohol now instead of vinegar/salt, but don't know which is best...

I also think that cleaning is even more important in my case, since I love 20g at 0.1ohm... I take 1-2sec pulls and adhere to breaks/amps of my cells(not cdr, but pulsed rates for my pulsing usage, and know how to workaround issues i.e. keep a cloth nearby, to quickly screw atty off if malfunction/stuck-button and don't leave unattended/take cells out when leaving home, and only take out 0.5ohm builds). I've tested maybe 20 builds in the last days from 26g to 20g, and from 0.35ohm to 0.1ohms, and always prefer dual 20g 4-5wrap 2.5mm id, for the warmth and dense/thickness(the higher ohm builds are fine also, but I much prefer short intensive pulls, than longer "lesser-intensive" ones). Dual parallels, the ones i've tried are to cold, but then I guess I need higher gauges like 26(only tried up to 24 I believe), or fewer wraps... I'm not good enough to make aliens/claptons etc. and refuse to buy premade wire/coils(cheating)... I also use parallel mechs 90% of the time though, which are less abusing on the cells...

@All

I have bought another toothbrush that is harder than the one before, and although I spend the same time and thoroughness on cleaning as before i.e. about 45 mins just for the alcohol scrubdown per mod, then I think it is helping, atleast for now on one of my smpl's which i've currently tested it with... I think it makes a difference on the 20mm threads... I also use alcohol now instead of vinegar/salt, but don't know which is best...

I also think that cleaning is even more important in my case, since I love 20g at 0.1ohm... I take 1-2sec pulls and adhere to breaks/amps of my cells(not cdr, but pulsed rates for my pulsing usage, and know how to workaround issues i.e. keep a cloth nearby, to quickly screw atty off if malfunction/stuck-button and don't leave unattended/take cells out when leaving home, and only take out 0.5ohm builds). I've tested maybe 20 builds in the last days from 26g to 20g, and from 0.35ohm to 0.1ohms, and always prefer dual 20g 4-5wrap 2.5mm id, for the warmth and dense/thickness(the higher ohm builds are fine also, but I much prefer short intensive pulls, than longer "lesser-intensive" ones). Dual parallels, the ones i've tried are to cold, but then I guess I need higher gauges like 26(only tried up to 24 I believe), or fewer wraps... I'm not good enough to make aliens/claptons etc. and refuse to buy premade wire/coils(cheating)... I also use parallel mechs 90% of the time though, which are less abusing on the cells...

Last edited:

Good idea. For any mech user, it wouldn't hurt to learn more than just Ohm's Law.... DC electronics is basic algebra, e.g. voltage dividers, resistors in series/parallel circuits.Thanks alot for that write-up duc!Very much appreciated! I'll have to read up a bit more on electricity, lol

Thanks again!

All this stuff reminds me of car audio back in the 80's.... a good installer knew how to calculate inductive/capacitive reactance, and could figure out the caps and coils needed to build 18 db/octave passive crossovers to dial in your cutoff frequencies for your subs and tweets. Then came active crossovers and that knowledge was lost, and any kid who could use a sawzall could become an installer. VV Mods remind me of those active crossovers... any fool could blow clouds when those hit the scene. But I digress...

Here's the thing about the springs.

Think of how the switch works.

It slides through the housing.

Contact in the housing is made when the button rides against the waves in the sides of the housing.

Side friction contact.

When the button touches the battery it doesn't bottom out on the housing, it bottoms out on the compressed spring.

This is even more relevant, the more the mod is used, and the greater the tolerances of the waves become due to the soft brass.

I've repaired mods for several B&Ms.

This is why engineers and mechanics rarely agree.

Think of how the switch works.

It slides through the housing.

Contact in the housing is made when the button rides against the waves in the sides of the housing.

Side friction contact.

When the button touches the battery it doesn't bottom out on the housing, it bottoms out on the compressed spring.

This is even more relevant, the more the mod is used, and the greater the tolerances of the waves become due to the soft brass.

I've repaired mods for several B&Ms.

This is why engineers and mechanics rarely agree.

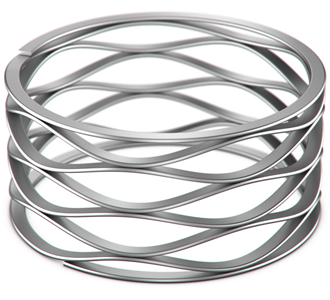

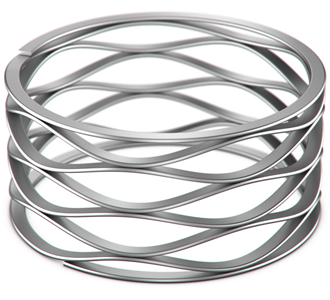

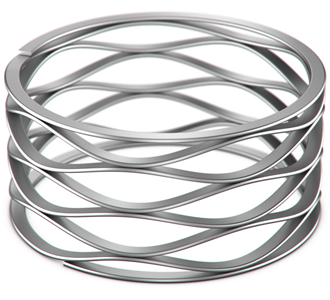

For anyone with hot button or collapsing spring issues, look in to wave springs with shim ends, I forget the size I ordered to fit the SMPL switch but they work fantastic. Wave springs have 10x the contact surface area of a standard round wire spring which makes them more reliable for current transfer.

This is why engineers and mechanics rarely agree.

Just FYI, I'm a mechanic too (but they call us Master Techs), at a Fortune 500 (VLSI ranked in top 5) semiconductor capital equipment company in Silicon Valley.

For anyone with hot button or collapsing spring issues, look in to wave springs with shim ends, I forget the size I ordered to fit the SMPL switch but they work fantastic. Wave springs have 10x the contact surface area of a standard round wire spring which makes them more reliable for current transfer.

We use springs like that to preload the robot arms (that carry silicon wafers). The ones we use are really stiff though. Where'd you source some soft ones for the SMPL?

Hmmm, do I detect someone that works at Applied Materials?

Good guess! I'll leave it at that.

I actually ordered a large pack of 50 assorted wave springs from somewhere, I cannot recall where I did but I was able to make one of them in that package work very nicely in my SMPL. As far as I can tell Smalley is the best source for these springs, the spring rate is listed all the way to the right measured in lb/in.We use springs like that to preload the robot arms (that carry silicon wafers). The ones we use are really stiff though. Where'd you source some soft ones for the SMPL?

CS Series

Stock SMPL spring measurements:

0.493" in external diameter

0.445" in internal diameter

0.429" overall height

SMPL switch measurements

0.372" Shaft diameter

0.560" maximum allowable spring width

You have some room to play with in external diameter and overall height but the internal diameter cannot be smaller than 0.445" if you want the spring to fit in the switch the way the stock spring does, you can use a smaller diameter spring like a 0.375 but the spring will ride on top of the milled ledge inside of the switch(still works this way but you need a slightly shorter spring). Keep in mind these measurements are all off an Authentic SMPL, my clones compare quite closely but due to the variable tolerance of the clones and differing switch designs I decided not to measure them for reference.

If you wanted the end-all-be-all, Smalley will even make you wave springs to your specifications in materials like Beryllium Copper;

Made-to-order springs available through Smalley’s No-Tooling-Charges™ process

Last edited:

Just FYI, I'm a mechanic too (but they call us Master Techs), at a Fortune 500 (VLSI ranked in top 5) semiconductor capital equipment company in Silicon Valley.

I'm not a master tech, but I used to custom manufacture parts that master techs use to solve problems presented by engineers.

- Status

- Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 4K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)