Hi!

Fellows, I'm in the process of restoring an old Ni-CD drill/screwdriver battery pack.

Jokes aside

Jokes aside

, the batteries are to be replaced by,

, the batteries are to be replaced by,  you know, a marriage of LiitoKala 26650-50A cells.

you know, a marriage of LiitoKala 26650-50A cells.

Well, since there are no known 20A discharge curves for these cells (besides the stuff available at 高一致性3.7V 5000mA镍钴锰酸锂三元锂电池 生产厂家|东莞力朗电池科技有限公司), I've come up with some extrapolation figures which I'd like to share in order to see if this makes enough sense.

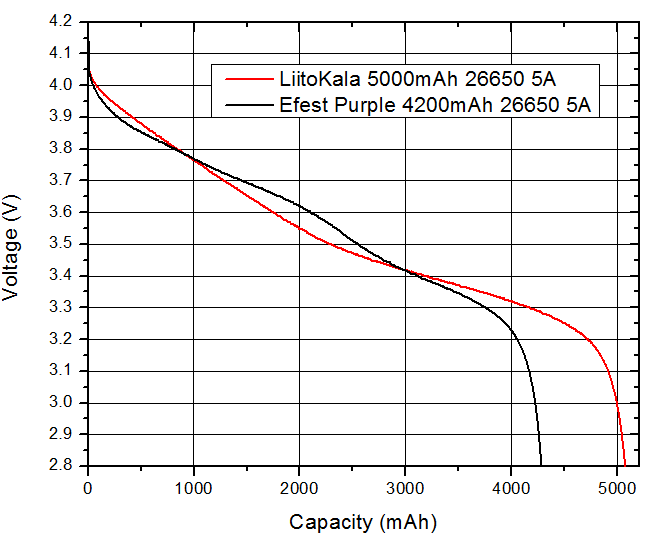

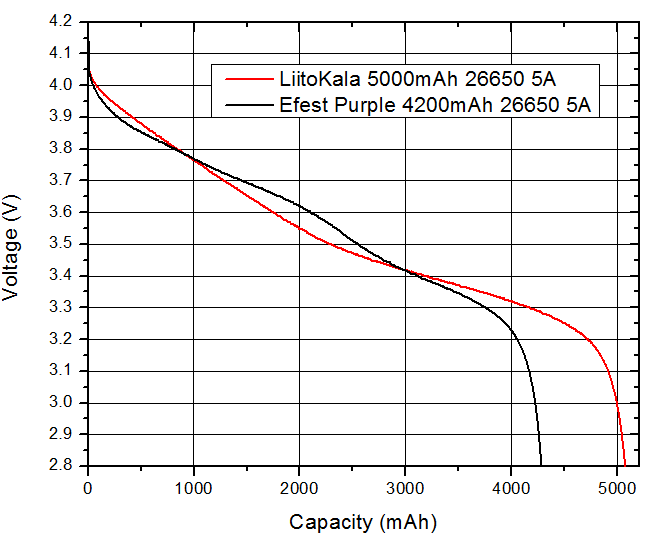

The material presented below is a discharge curve done through a 300W Turnigy Reaktor hobby charger and the voltage was monitored right at the cell contacts using a Junsi Powerlogger 6S. Source: EasyB's #118 post at “LiitoKala 26650-50A 5000mah 26650 - great first impressions” BLF thread.

First of all, the curves seem to start a bit below where it should, in my opinion, for a battery with no more than 23mΩ of internal resistance. At least 35mV, as I see it. So the testing setup may had some stray resistance, doesn't it? A minor detail, of course.

First of all, the curves seem to start a bit below where it should, in my opinion, for a battery with no more than 23mΩ of internal resistance. At least 35mV, as I see it. So the testing setup may had some stray resistance, doesn't it? A minor detail, of course.

Well, the key here for me is to attain a good idea of the expected capacity at 20A discharge rate. The 20A curve should have a voltage offset of current delta times Rbatt, so (20 - 5) × 0.023Ω ≈ 0.35V, no more.

With this figure in mind, I thus see close to 4.9Ah of capacity at 20A rate with 2.8V cutoff, and almost 4.5Ah if we step up the cutoff to 2.9V, which is the figure for the BMS I bought (tad high, doesn't it?

).

).

Well, that's all for now folks.

I'll be glad to hear from you.

Cheers

Fellows, I'm in the process of restoring an old Ni-CD drill/screwdriver battery pack.

you know, a marriage of LiitoKala 26650-50A cells.

you know, a marriage of LiitoKala 26650-50A cells.Well, since there are no known 20A discharge curves for these cells (besides the stuff available at 高一致性3.7V 5000mA镍钴锰酸锂三元锂电池 生产厂家|东莞力朗电池科技有限公司), I've come up with some extrapolation figures which I'd like to share in order to see if this makes enough sense.

The material presented below is a discharge curve done through a 300W Turnigy Reaktor hobby charger and the voltage was monitored right at the cell contacts using a Junsi Powerlogger 6S. Source: EasyB's #118 post at “LiitoKala 26650-50A 5000mah 26650 - great first impressions” BLF thread.

Well, the key here for me is to attain a good idea of the expected capacity at 20A discharge rate. The 20A curve should have a voltage offset of current delta times Rbatt, so (20 - 5) × 0.023Ω ≈ 0.35V, no more.

With this figure in mind, I thus see close to 4.9Ah of capacity at 20A rate with 2.8V cutoff, and almost 4.5Ah if we step up the cutoff to 2.9V, which is the figure for the BMS I bought (tad high, doesn't it?

Well, that's all for now folks.

I'll be glad to hear from you.

Cheers