Hey Everyone-

Well, I've been busy in the shop with the Major Wood Holder. I have a few more pics:

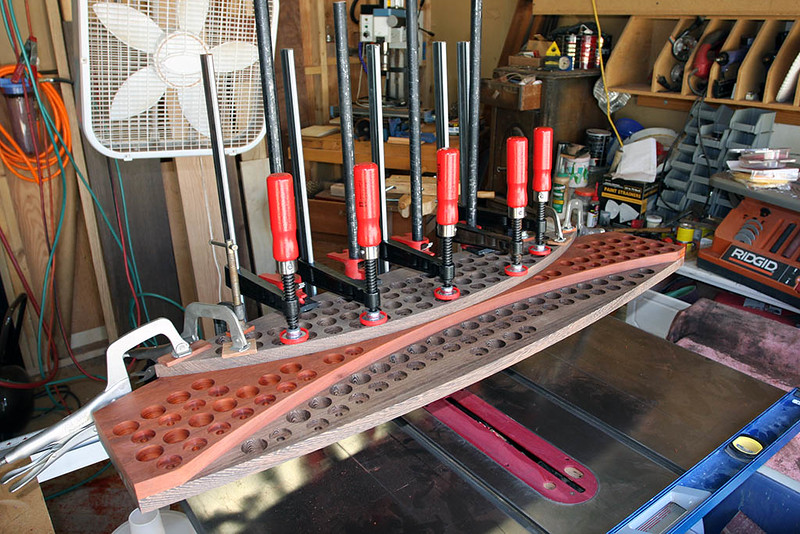

This is the clamp up of the bottom two layers - it's upside down in this shot. Took 20 clamps to properly compress the glue up.

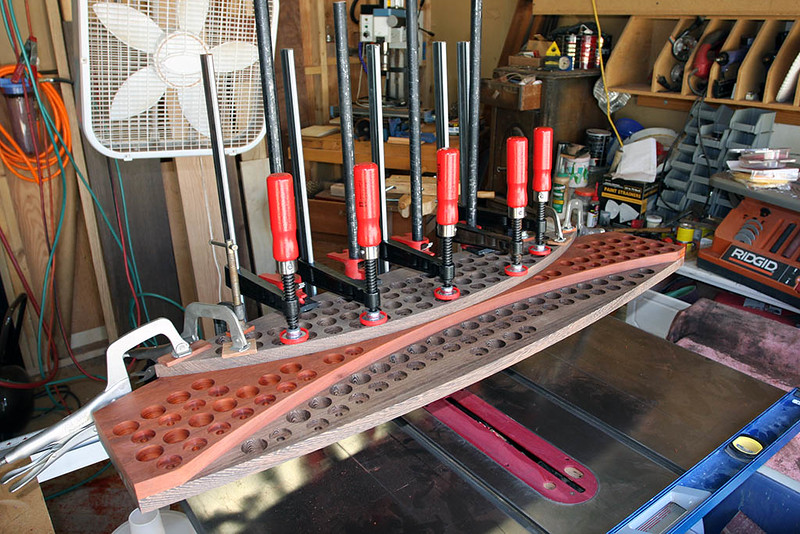

Here's another view of the same clamp up. Great looking edge grain on the Wenge. Hard to tell from this shot, but the Padauk (red) is hanging over the Wenge, and will be trimmed off.

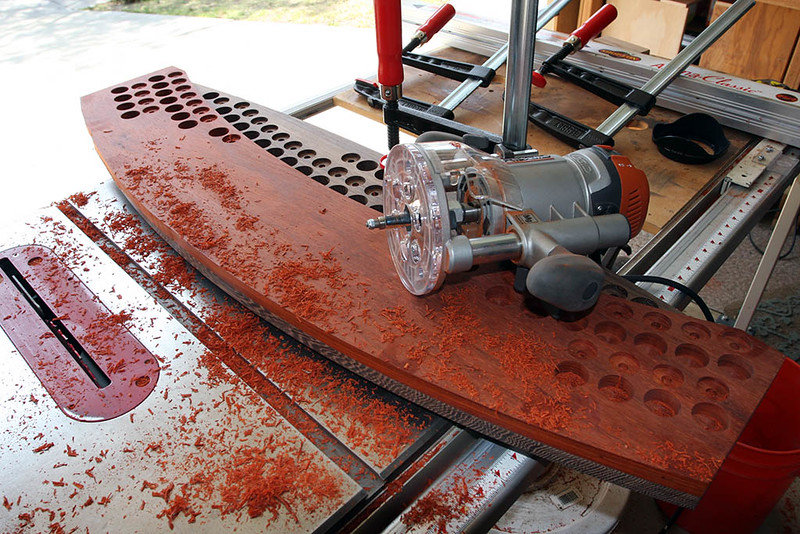

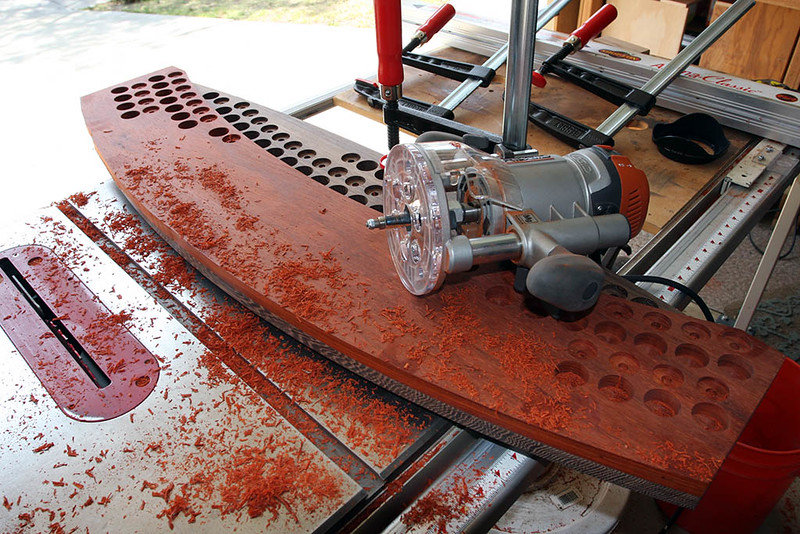

Here are the two pieces out of the clamps - right side up. Trimming the Padauk flush with the bottom layer of Wenge. A little sanding of the trimmed edges, and it's ready for the third and final piece.

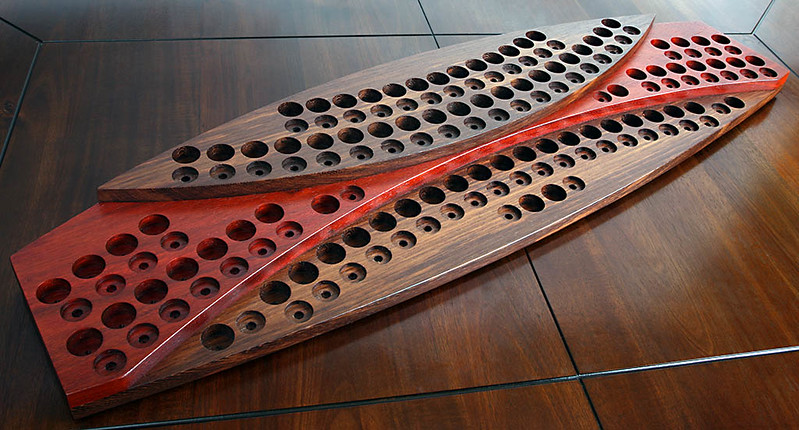

The last piece glued and clamped in place. Once out of the clamps, one more trim across the back & some sanding - the fabrication and assembly are complete! Tomorrow it will get it's soak in oil finish then about three days to fully dry before start of the clear coats. Big holder.

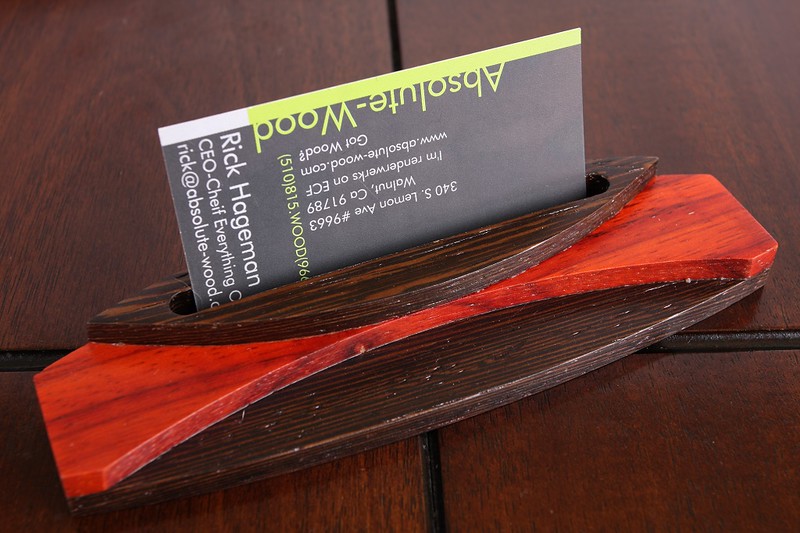

Some holders, however, aren't so big at all... Not much bigger than a business card...

Not much bigger than a business card...

Rick

Well, I've been busy in the shop with the Major Wood Holder. I have a few more pics:

This is the clamp up of the bottom two layers - it's upside down in this shot. Took 20 clamps to properly compress the glue up.

Here's another view of the same clamp up. Great looking edge grain on the Wenge. Hard to tell from this shot, but the Padauk (red) is hanging over the Wenge, and will be trimmed off.

Here are the two pieces out of the clamps - right side up. Trimming the Padauk flush with the bottom layer of Wenge. A little sanding of the trimmed edges, and it's ready for the third and final piece.

The last piece glued and clamped in place. Once out of the clamps, one more trim across the back & some sanding - the fabrication and assembly are complete! Tomorrow it will get it's soak in oil finish then about three days to fully dry before start of the clear coats. Big holder.

Some holders, however, aren't so big at all...

Rick