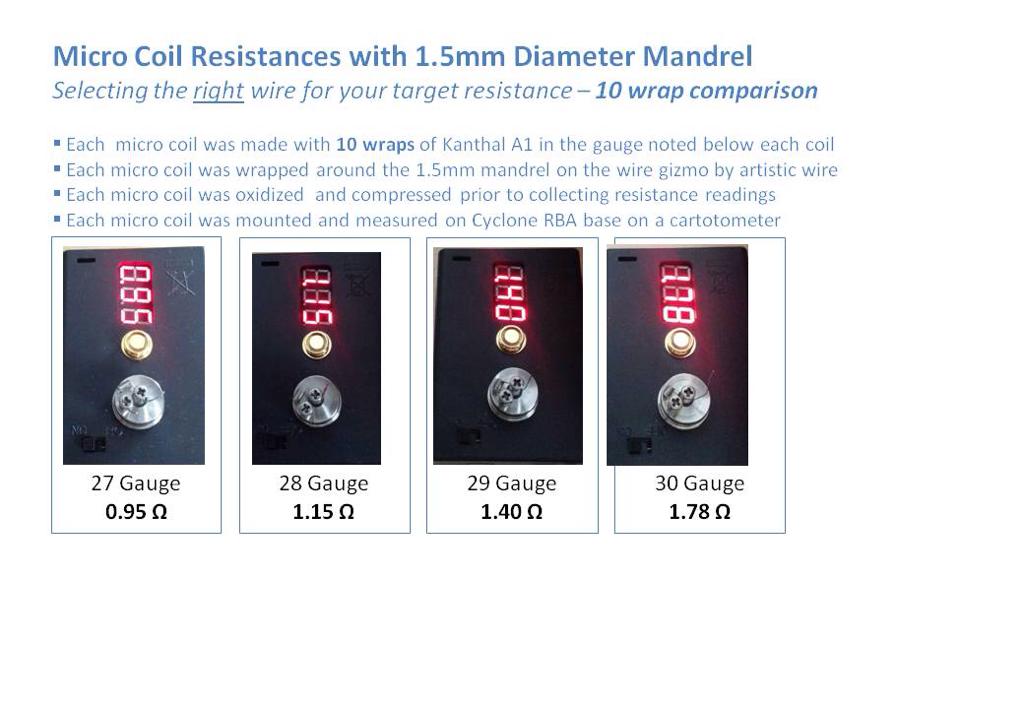

When building micro coils, It's important to select the correct wire to hit your target resistance (ohms) when you build a coil

I like to use 10 or 11 wraps to get my resistance. These days I have a preference of 1.3 to 1.5 ohms.

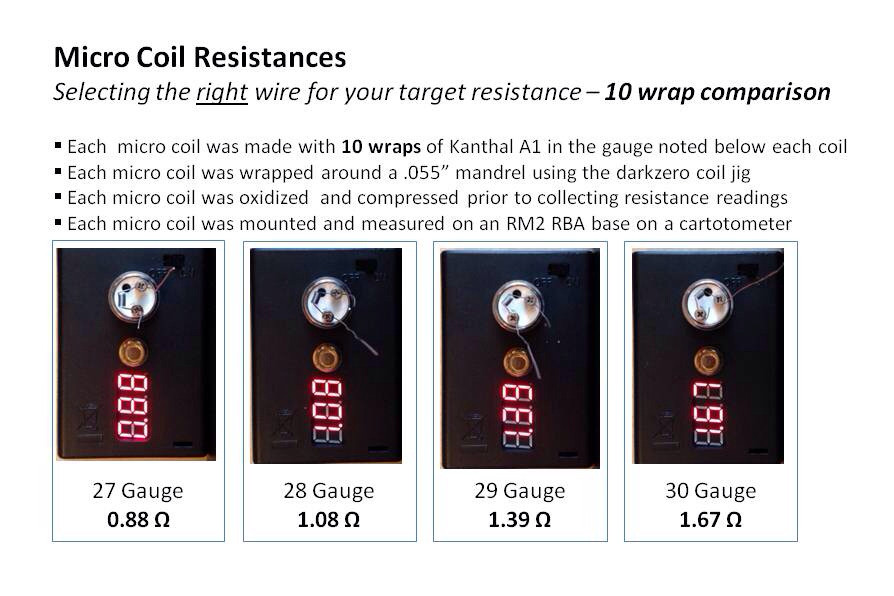

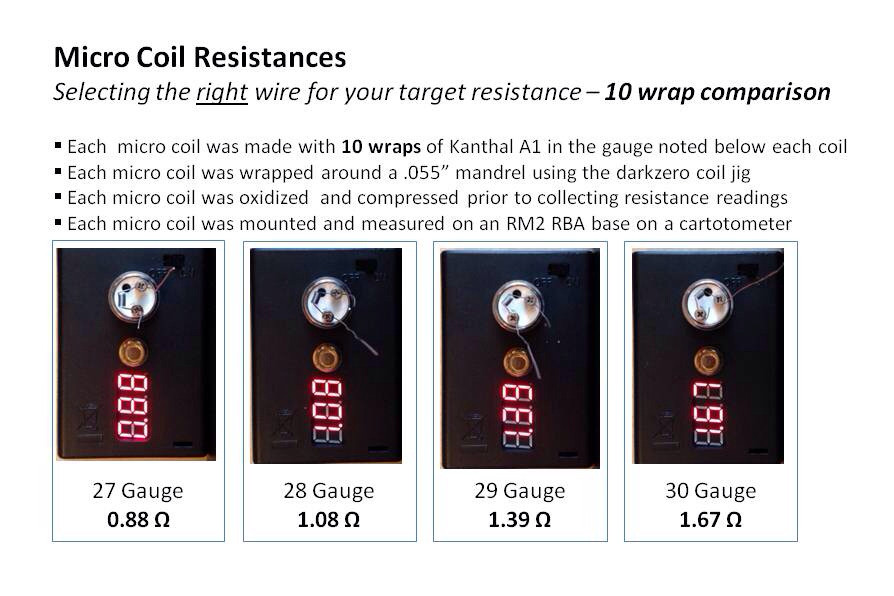

This handy chart can take the guesswork out of it for you. Here I rolled up 10 wrap micro coils around the .055" mandrel on the darkzero coil jig using 27, 28, 29 & 30 gauge Kanthal A1. The chart will indicate that 29 gauge is the correct wire for me to use to get the resistance I want in my coil.

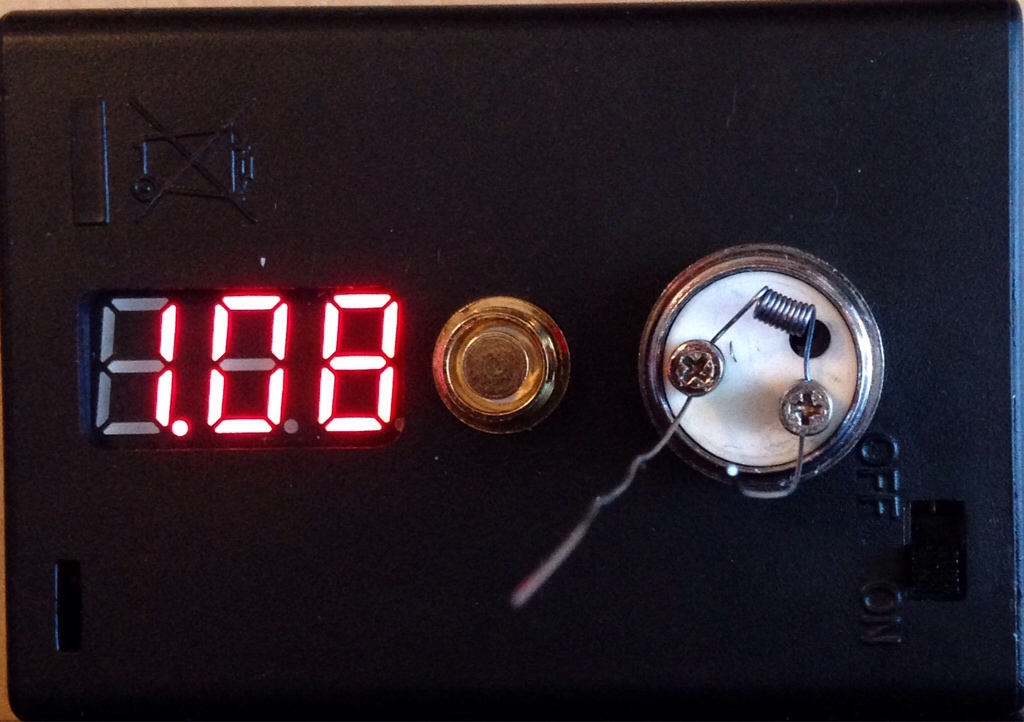

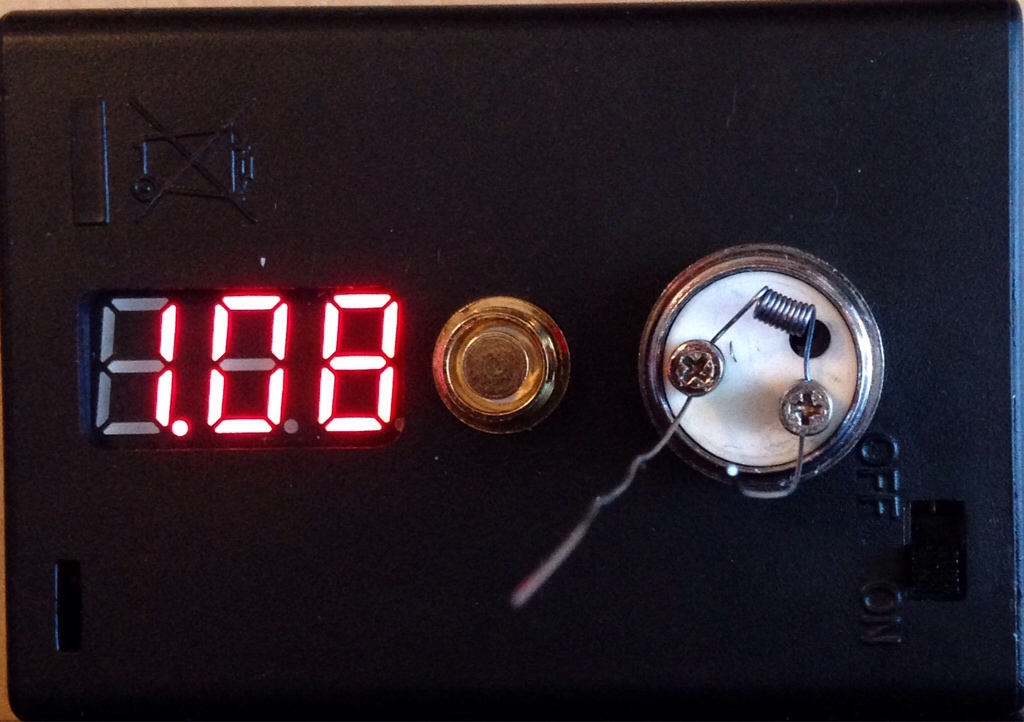

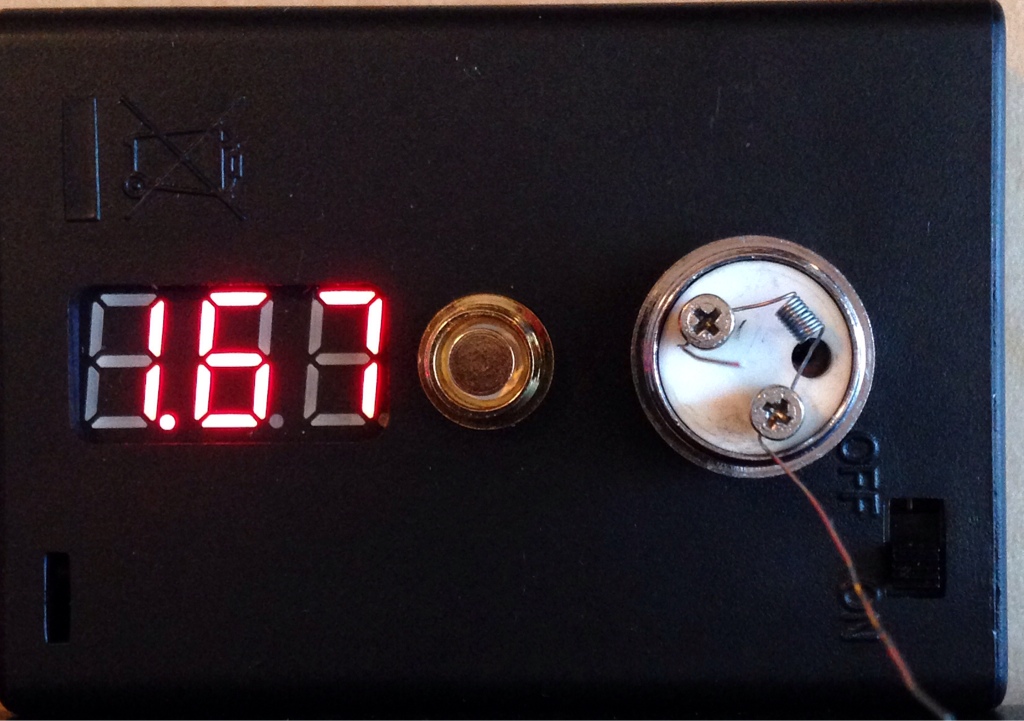

27 ga:

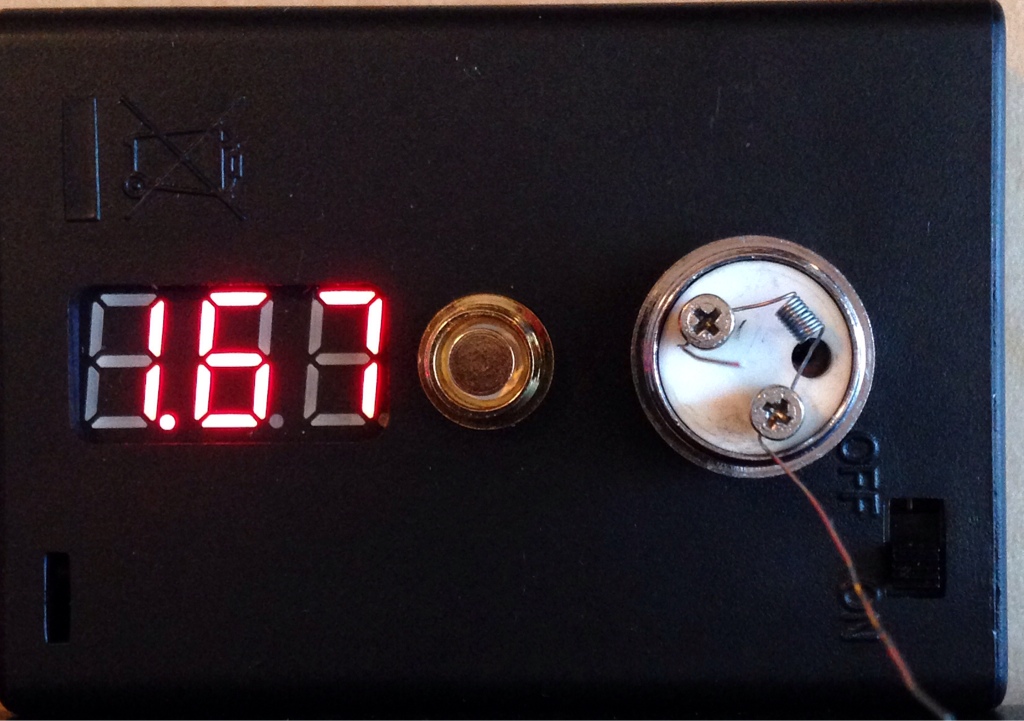

28 ga:

29 ga:

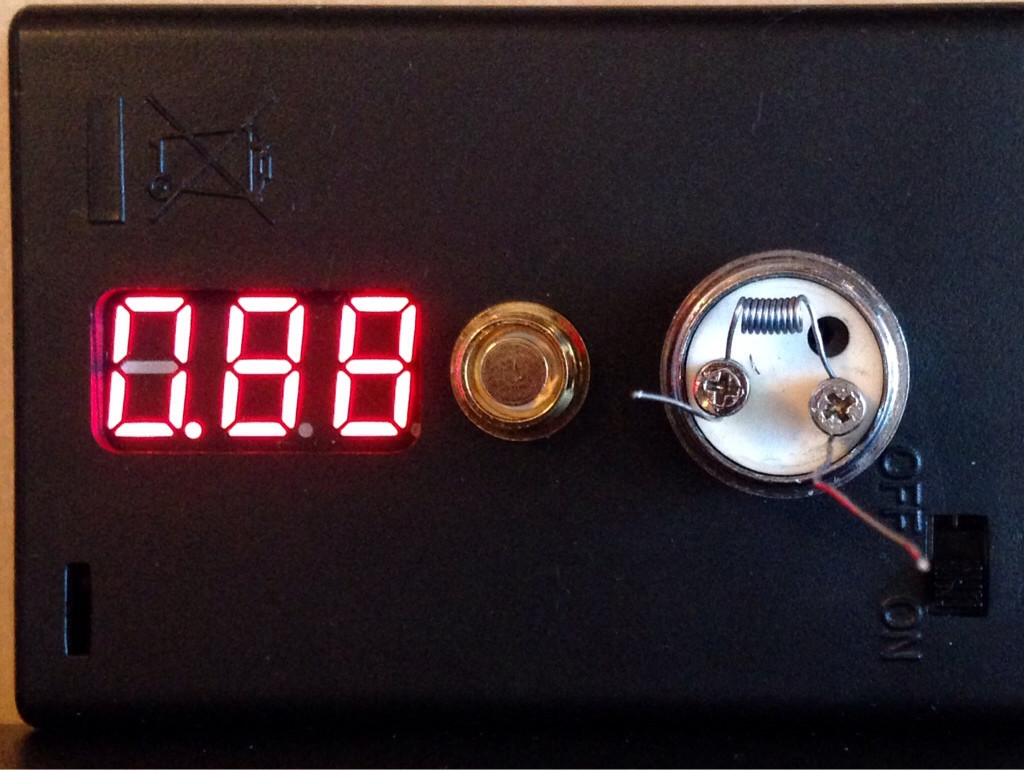

30 ga:

I made the following notes during this exercise, noting that it's the first time I've ever used 4 different gauges back to back:

27 ga - the screws tend to loosen up if the coil is even subtly moved.

29 ga - perfect balance between ease of wrapping and wire thickness. Screws stay nice and tight.

30 ga - feels extremely thin. The most difficult to wrap a micro coil with. Deforms easily.

I like to use 10 or 11 wraps to get my resistance. These days I have a preference of 1.3 to 1.5 ohms.

This handy chart can take the guesswork out of it for you. Here I rolled up 10 wrap micro coils around the .055" mandrel on the darkzero coil jig using 27, 28, 29 & 30 gauge Kanthal A1. The chart will indicate that 29 gauge is the correct wire for me to use to get the resistance I want in my coil.

27 ga:

28 ga:

29 ga:

30 ga:

I made the following notes during this exercise, noting that it's the first time I've ever used 4 different gauges back to back:

27 ga - the screws tend to loosen up if the coil is even subtly moved.

29 ga - perfect balance between ease of wrapping and wire thickness. Screws stay nice and tight.

30 ga - feels extremely thin. The most difficult to wrap a micro coil with. Deforms easily.

Last edited: