I fixed it I realized after

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mike n Tibs DNA Mods!

- Thread starter Proetus

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

Up early, bored and nothing good on TV so I turned to mod and tank maintenance. I noticed something while cleaning my 510 connections, a small shinny spot on the center pin of my VT 510. I cleaned both the center pin on my tank and the 510 with some alcohol and then coated it with magic marker ink, let it dry then screwed the tank on and off a dozen times. What I found is I'm getting very little contact between the pins, checking both pins under a good magnifying glass I see there is a tiny nub in the very center of the 510 pin, a high spot left from the machining.

While I haven't had any problems with resistance changing and I only vape around 20W I'm going to sand the pin in both the tanks and the 510's until I get a better connection. When I built the mods, before installing the 510's I found a drill bit the fit tight in the soldering hole of the 510 pins and used the bit to spin the pin, using some fine sand paper I took the sharp edges off and put a radius on the sides of the pins, see the pic below. I had noticed when I pushed the pin down with a screw driver it had a gritty feel to it, once I rounded the edges off that was gone. I did that because I didn't want the pins to bind when screwing an atty on and have the pin stick and sit cocked/tilted. While I solved that I never checked with the magic marker trick to see if I was getting good contact. Just something to think about, may not ever be an issue but taking a few minuets to fine tune things as you build may prevent issues down the road, maybe more so for those that push the power....

BTW, using a magic marker for checking where parts rub against each other is a handy trick. I also use the ink to scribe my layouts when build things, a couple more pics below.

Polished pin on right, best I could do on the focus.

While I haven't had any problems with resistance changing and I only vape around 20W I'm going to sand the pin in both the tanks and the 510's until I get a better connection. When I built the mods, before installing the 510's I found a drill bit the fit tight in the soldering hole of the 510 pins and used the bit to spin the pin, using some fine sand paper I took the sharp edges off and put a radius on the sides of the pins, see the pic below. I had noticed when I pushed the pin down with a screw driver it had a gritty feel to it, once I rounded the edges off that was gone. I did that because I didn't want the pins to bind when screwing an atty on and have the pin stick and sit cocked/tilted. While I solved that I never checked with the magic marker trick to see if I was getting good contact. Just something to think about, may not ever be an issue but taking a few minuets to fine tune things as you build may prevent issues down the road, maybe more so for those that push the power....

BTW, using a magic marker for checking where parts rub against each other is a handy trick. I also use the ink to scribe my layouts when build things, a couple more pics below.

Polished pin on right, best I could do on the focus.

A little disappointed that the color is slightly different.

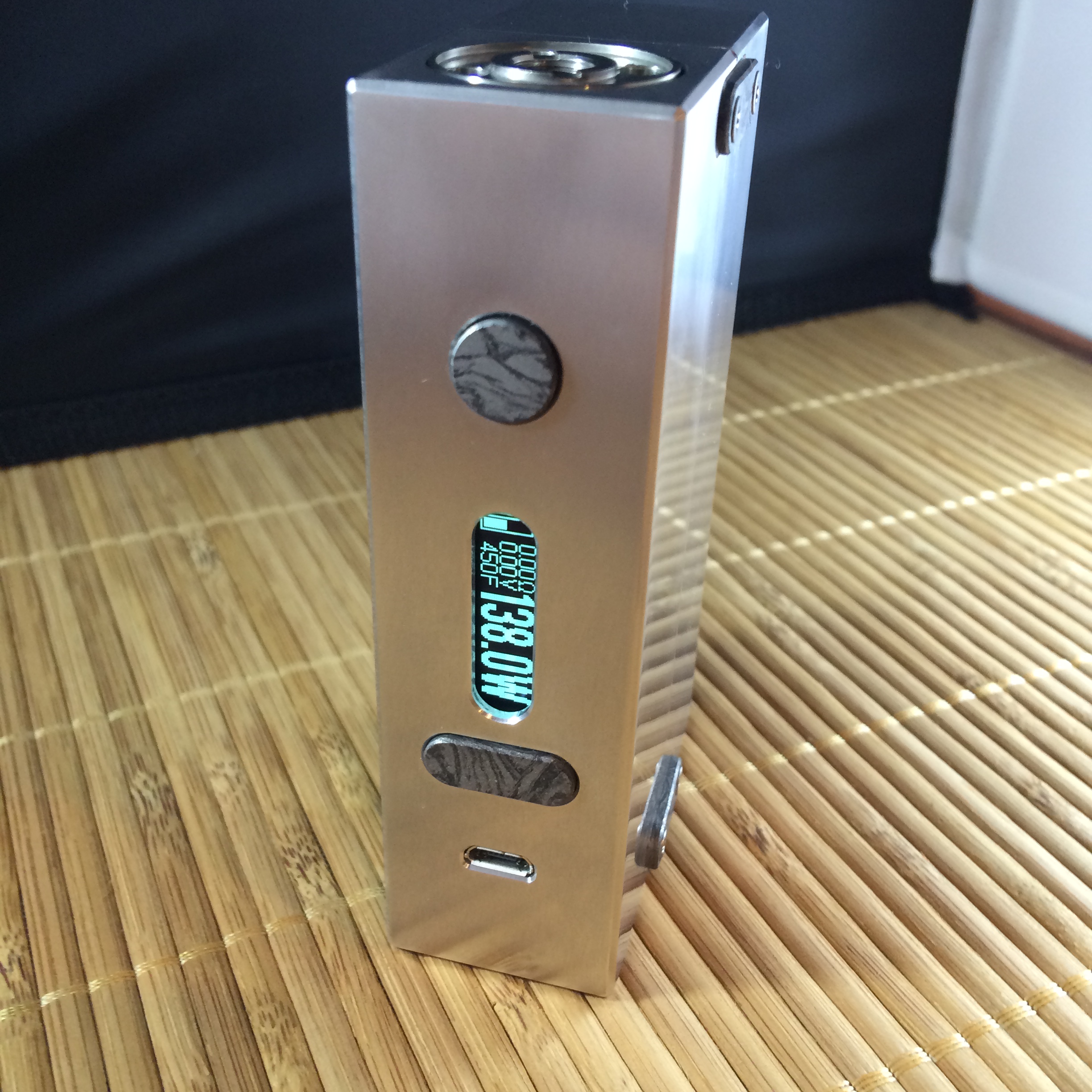

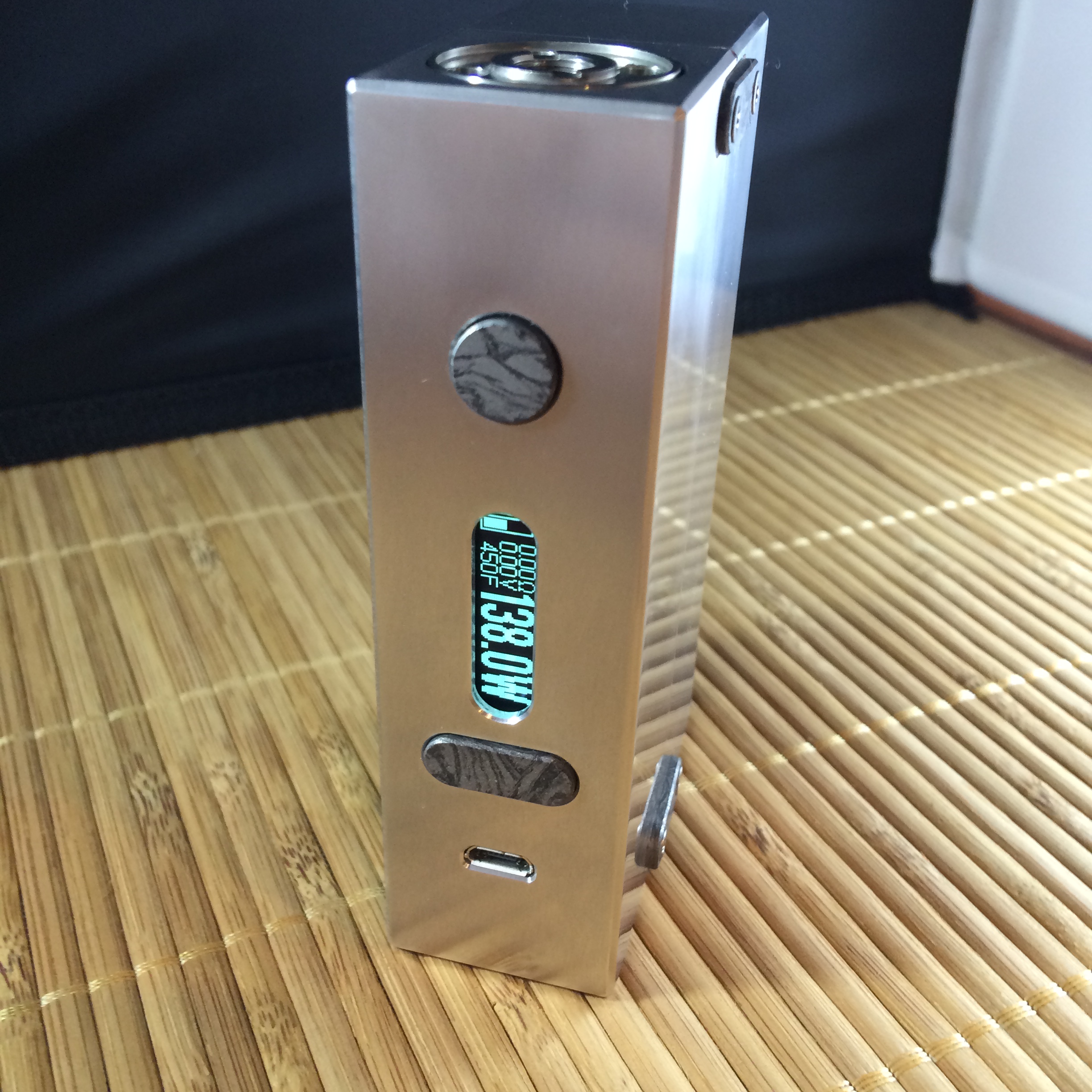

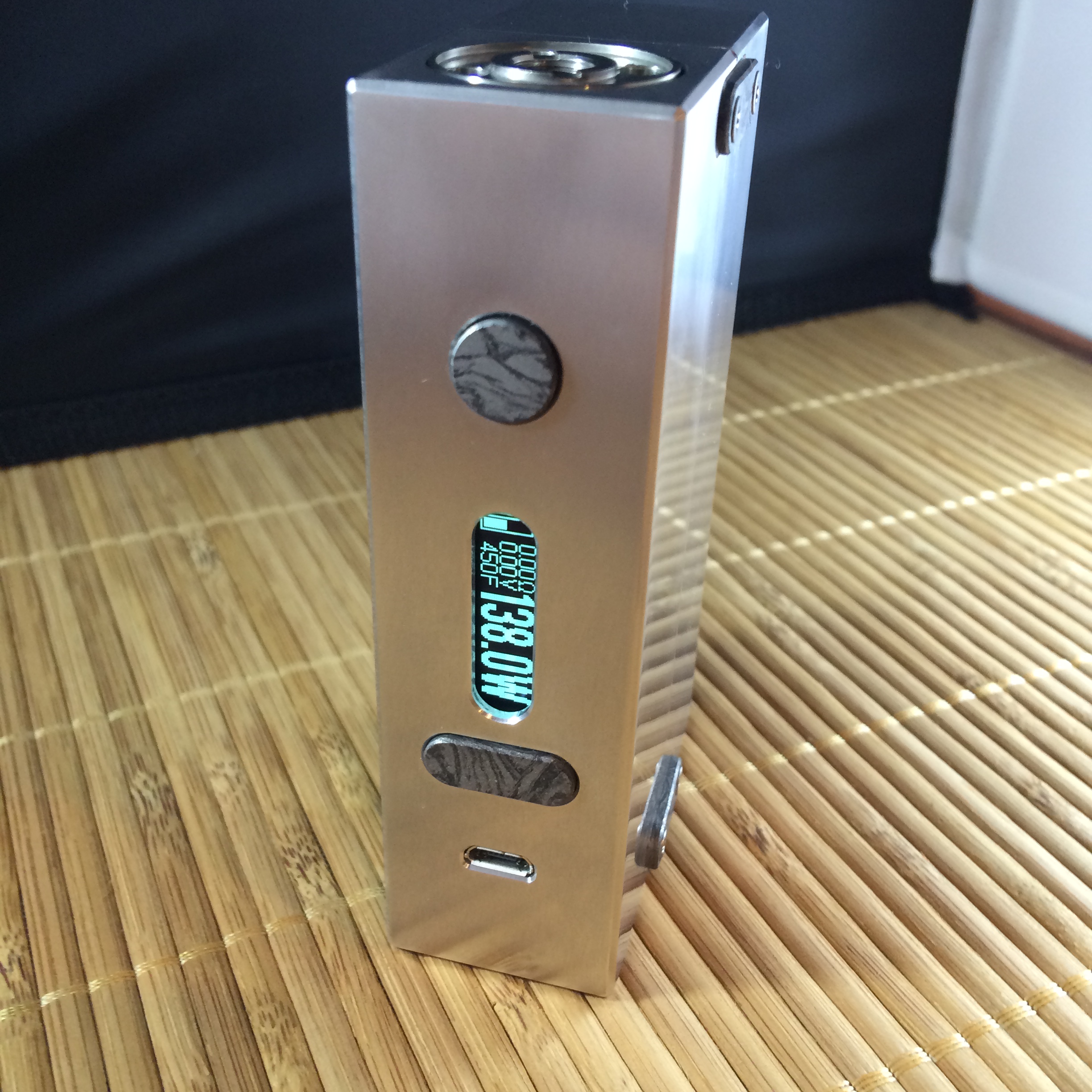

Finally got my split body DNA200 mod done. It's machined from 6061 aluminum and the buttons and side plates are made from damascus style M3 Mokume. There are a couple of small issues I need to address on the next build and the raw aluminum is a fingerprint magnet. Full photo album here:

Most excellent!!

Finally got my split body DNA200 mod done. It's machined from 6061 aluminum and the buttons and side plates are made from damascus style M3 Mokume. There are a couple of small issues I need to address on the next build and the raw aluminum is a fingerprint magnet. Full photo album here:

Awesome. It must be so cool to have access (or own?) one of those machines.... very nice design. I think I like the little bridge clips on the sides to keep the clam shell together. My only criticism is I personally like the square screen more than the oval (hana) style screen cut...but thats just me YMMV. Two thumbs way up!

Awesome. It must be so cool to have access (or own?) one of those machines.... very nice design. I think I like the little bridge clips on the sides to keep the clam shell together. My only criticism is I personally like the square screen more than the oval (hana) style screen cut...but thats just me YMMV. Two thumbs way up!

Thanks, I own the mill ... bought it in April and it sits on one side of my two car garage ... car still fits on the other side! It is very cool and I feel extremely fortunate to be able to pursue this hobby with a great set of tools.

Thanks, I own the mill ... bought it in April and it sits on one side of my two car garage ... car still fits on the other side! It is very cool and I feel extremely fortunate to be able to pursue this hobby with a great set of tools.

So at the risk of sounding rude which I do NOT intend, and I mean no offense... what does a machine like that cost? how much are the blank aluminum "rods"? I'm guessing the end resulting cost of creating such a box is fairly minimal? (minus the cost of the mill obviously which Im guessing is crazy expensive). Obviously nobody buys a device like that to build mods...you use that for other reasons. (again, I'm not trying to offend you, just my inner geek is curious... I have a cell phone store, and needed some vinyl lettering done, so because I'm a geek - I bought a 36 inch commercial grade vinyl plotter (preowned) that I've used twice in several years, and my wife likes to throw it in my face from time to time)

So at the risk of sounding rude which I do NOT intend, and I mean no offense... what does a machine like that cost? how much are the blank aluminum "rods"? I'm guessing the end resulting cost of creating such a box is fairly minimal? (minus the cost of the mill obviously which Im guessing is crazy expensive). Obviously nobody buys a device like that to build mods...you use that for other reasons. (again, I'm not trying to offend you, just my inner geek is curious... I have a cell phone store, and needed some vinyl lettering done, so because I'm a geek - I bought a 36 inch commercial grade vinyl plotter (preowned) that I've used twice in several years, and my wife likes to throw it in my face from time to time)

No offense taken, I'm happy to answer any questions.

Aluminum right now isn't terribly expensive, it was probably around 5 or 6 dollars of raw materials. The M3 Mokume for the buttons and side plates was WAY more ... something like $50.

CNC machining is an expensive hobby, not necessarily because of the mill but because of all of the other stuff you need to have. Tool holders, vises, end mills, metal cutting saw, coolant system, air compressor, measurement and setup tools, etc. The running joke is that the price of the mill is just a down payment on the tooling. For just the mill head you'd pay around $6800 ... of course just having the mill head doesn't do you a lot of good and everything is an add-on! I'm probably in closer to 25K after all is said and done.

The better the conductivity, the better. But I would say most any common metal would work. If you find them let us know, these titanium ones were the only one I could find. Its not a common thread pitch on M7 screws.

Couldn't find them locallly...I Looked at 3 places yesterday... only Ace hardware had a M7 at al but the M7 thread pitch was 1.0 and NOT 0.5, so it wouldnt thread...M6 and M8 do not fit (and are much more common sizes), obviously too small/large respectively... and none of the imperial (USA/non metric) sizes are quite right. So unless you order them online, it looks like @VapingBad has the best solution, sacrifice "something" with a 510 per his suggestions... I need to go thru my parts bin and see what I have, I think I have some old protanks, (clone) taifun gt1 bases, etc... I just need to take the time to look...

I really want to run this test on my dna200 flask, and also the case analyzer too. I think the case analyzer you just need your rooms temperature and let it sit connected for a few hours right?

No offense taken, I'm happy to answer any questions.

Aluminum right now isn't terribly expensive, it was probably around 5 or 6 dollars of raw materials. The M3 Mokume for the buttons and side plates was WAY more ... something like $50.

CNC machining is an expensive hobby, not necessarily because of the mill but because of all of the other stuff you need to have. Tool holders, vises, end mills, metal cutting saw, coolant system, air compressor, measurement and setup tools, etc. The running joke is that the price of the mill is just a down payment on the tooling. For just the mill head you'd pay around $6800 ... of course just having the mill head doesn't do you a lot of good and everything is an add-on! I'm probably in closer to 25K after all is said and done.

Sounds about right... M3 Mokume, whoa dude... I would have chosen another material at that price. wow. Looks good tho

There is a place here in my area, where they charge you $50/month for 24/7 access to these various workshops... 3d printers, machine shops, mechanics shops, wood working shops, etc... its essentially a big sectioned off warehouse with tons of tools for just about any task imaginable. You supply the material be it aluminum, printing filament, or a transmission or brake rotors, and if your a member, you can go there, use the workspace/garage and any and all tools. Its a community driven thing where other members help each other, etc... That would be awesome for stuff like this for a guy like me. Alas, I'm lazy and old...and even tho I know about this place, sometimes its easier just to order/buy what you want or whats available than to try and design, build, cnc, inevitability troubleshoot the creative alpha versions, redo and do create the beta versions, etc...

Couldn't find them locallly...I Looked at 3 places yesterday... only Ace hardware had a M7 at al but the M7 thread pitch was 1.0 and NOT 0.5, so it wouldnt thread...M6 and M8 do not fit (and are much more common sizes), obviously too small/large respectively... and none of the imperial (USA/non metric) sizes are quite right. So unless you order them online, it looks like @VapingBad has the best solution, sacrifice "something" with a 510 per his suggestions... I need to go thru my parts bin and see what I have, I think I have some old protanks, (clone) taifun gt1 bases, etc... I just need to take the time to look...

I really want to run this test on my dna200 flask, and also the case analyzer too. I think the case analyzer you just need your rooms temperature and let it sit connected for a few hours right?

I went through the same thing looking for a bolt and nuts, I wanted to make a tool to hold 510's tight while I tighten the nuts inside the mods. Then someone posted about the Fat Daddy Vapes tool, I ordered those, they come in a pair, about 1/3 way down on the page right side --> SHOP - FatDaddyVapes.com - Home of the best vape tweaks and replacement hardware. This tool rocks! It holds the 510 as tight as you want it too, I love them! I put a thin copper washer between the nut and the face of the 510 so I don''t mark up the 510. You could take the nut off and screw this in and use it to check the resistance.

Sounds about right... M3 Mokume, whoa dude... I would have chosen another material at that price. wow. Looks good tho

There is a place here in my area, where they charge you $50/month for 24/7 access to these various workshops... 3d printers, machine shops, mechanics shops, wood working shops, etc... its essentially a big sectioned off warehouse with tons of tools for just about any task imaginable. You supply the material be it aluminum, printing filament, or a transmission or brake rotors, and if your a member, you can go there, use the workspace/garage and any and all tools. Its a community driven thing where other members help each other, etc... That would be awesome for stuff like this for a guy like me. Alas, I'm lazy and old...and even tho I know about this place, sometimes its easier just to order/buy what you want or whats available than to try and design, build, cnc, inevitability troubleshoot the creative alpha versions, redo and do create the beta versions, etc...

Wow, wish there was a place like that near me! I took a couple years of machine trade, I wanted to follow in my Father's foot steps and become a machinist but I ended up twisting wrenches for a living, I have most of Dad's tool's, no one wanted them after he passed. I'm happy and proud to have them, they mean a lot to me.

The M3 Mokume for the buttons and side plates was WAY more ... something like $50.

OK I take it back, I looked up this stuff, its beyond gorgeous. Its marbled metal, and comes in amazing color combination that adds a touch of class to your mod, I tip my hat to you sir.

OK I take it back, I looked up this stuff, its beyond gorgeous. Its marbled metal, and comes in amazing color combination that adds a touch of class to your mod, I tip my hat to you sir.

M3 Mokume is an interesting material ... powdered metal and resin and yeah it comes in some really wild combinations. It is absolutely brutal machining the stuff and acts like an abrasive on the end mills so I'm about done working with it. Found another interesting product that is an acrylic typically used on knife and gun handles called Kirinite. It's also much more reasonably priced!

Wow, wish there was a place like that near me! I took a couple years of machine trade, I wanted to follow in my Father's foot steps and become a machinist but I ended up twisting wrenches for a living, I have most of Dad's tool's, no one wanted them after he passed. I'm happy and proud to have them, they mean a lot to me.

And there may be such a place, I found this by mistake...looking for a local 3d printer... Here its called Dallas Makerspace Dallas Makerspace | A Community Workshop

M3 Mokume is an interesting material ... powdered metal and resin and yeah it comes in some really wild combinations. It is absolutely brutal machining the stuff and acts like an abrasive on the end mills so I'm about done working with it. Found another interesting product that is an acrylic typically used on knife and gun handles called Kirinite. It's also much more reasonably priced!

The site I went to for the Mokume was essentially blanks for Pens... and yeah, expensive. But man did I see some color combos that looked awesome.

Here's some pics of that FDV 510 tool and while I was at it I took a few pics of a couple other things I've been wanting to share. The 510 tool can be used to hole the 510 in a vise while you tighten the nut inside the mod or you can hold the nut still and turn the 510 with an allen wrench to tighten. You could use a grounding ring for a washer to protect the finish on the 510, any soft metal washer will work.

Here's the $9 helping hands I came up with, they work great and I don't know how I did without them! The tubes were from Amazon, slow boat from China took a month to get here but for $5 shipped the price is right --> http://www.amazon.com/gp/product/B008O14864 The clips cost me $4 at the local electronic shop. The base is a machinist parallel, one my Dad made many years ago, the holes just happen to be 1/2 inch, same size as the base on the pipes. They fit a tad loose so I put a thin coat of J-B Weld on them then sanded a little until they fit in snug. A piece of wood with some 1/2 inch holes would work just fine, you could add some weight to the block if needed. The magnifying glass was from the junk drawer, it just happen to fit nicely in the pipe!

These little heat sinks I modified to fit around the striped wire, it really helps to keep the solder from wicking up into the wire. I striped a couple different gage wire, measured the core and used drill bits from my numbered drill set, I spun the bits with a pin vise by hand and let the pressure of the jaws do the cutting.

Here's the $9 helping hands I came up with, they work great and I don't know how I did without them! The tubes were from Amazon, slow boat from China took a month to get here but for $5 shipped the price is right --> http://www.amazon.com/gp/product/B008O14864 The clips cost me $4 at the local electronic shop. The base is a machinist parallel, one my Dad made many years ago, the holes just happen to be 1/2 inch, same size as the base on the pipes. They fit a tad loose so I put a thin coat of J-B Weld on them then sanded a little until they fit in snug. A piece of wood with some 1/2 inch holes would work just fine, you could add some weight to the block if needed. The magnifying glass was from the junk drawer, it just happen to fit nicely in the pipe!

These little heat sinks I modified to fit around the striped wire, it really helps to keep the solder from wicking up into the wire. I striped a couple different gage wire, measured the core and used drill bits from my numbered drill set, I spun the bits with a pin vise by hand and let the pressure of the jaws do the cutting.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 876

- Replies

- 6

- Views

- 822

- Replies

- 24

- Views

- 2K

- Replies

- 0

- Views

- 215

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)