OK folks, I'm not an expert by any means, but I have got to say something after what I saw on another forum (a guy wanting to sub-ohm and asking for cloud builds without having an ohm meter or multimeter) and seeing things like Shari just asked (about building with the Ti wire for her ProVari, no offence intended) I just have to explain how to calculate wire length for resistance and to control what's going on before you even get started.

So here we go:

Kanthal (Nichrome, the above mentioned titanium) is a resistance wire, meaning it resists the flow of electricity. When it does this, it converts that electrical energy into light and heat... and with ejuice and a wick, vapor. *grin*

So, here is the simplest way to know for sure what your resistance will be: measure your wire (to the 1/16"). Every gauge of wire as its own resistance and is clearly listed online (see temco

http://www.temcoindustrialpower.com/product_selection.html?p=kanthal_a1 for more complete info) but here is a general listing of resistance per inch of the most commonly used sizes for vaping.

22ga(.64mm) - 0.109 ohms/in

24ga(.51mm) - 0.173 ohms/in

26ga(.40mm) - 0.276 ohms/in

28ga(.32mm) - 0.439 ohms/in

29ga(.29mm) - 0.546 ohms/in

30ga(.25mm) - 0.697 ohms/in

32ga(.20mm) - 1.091 ohms/in

34ga(.16mm) - 1.758 ohms/in

36ga(.13mm) - 2.783 ohms/in

And yes, I listed the metric diameter because many suppliers list it on the packaging as well as the AWG (American Wire Gauge) and because we have overseas folks here too. The higher gauge wires (34 and up) are normally used in rebuilding atomizer heads, like those used in protanks and the larger diameter wires are mostly used in low ohm and sub-ohm vaping as they have more room in the build area and they are looking for lower resistance.

************

Now, let's get a bit creative and build something just to show we can prove what we just learned... OK?

Lets go with Shari's example, a 1.2 ohm coil on a 2mm (1.98mm or 1/16" is a true microcoil). Now, since this is going on her Russian 91%, we have some room to work with in terms of wire but we're going to use 28ga for this example.

Looking at the chart above you see that 28ga wire has a resistance of 0.439 ohms/in, and that means that all we have to do is divide the resistance we want by the natural resistance of the wire (1.2÷0.439=2.73in or 69mm). For those of you with Vapers Toolbox on Android, it should read 2 5/8" and those on computer can check Steam Engine (

http://www.steam-engine.org/coil.asp) will see 67mm. The calculator method isn't perfect, but being slightly *high* in resistance is always better than being slightly low.

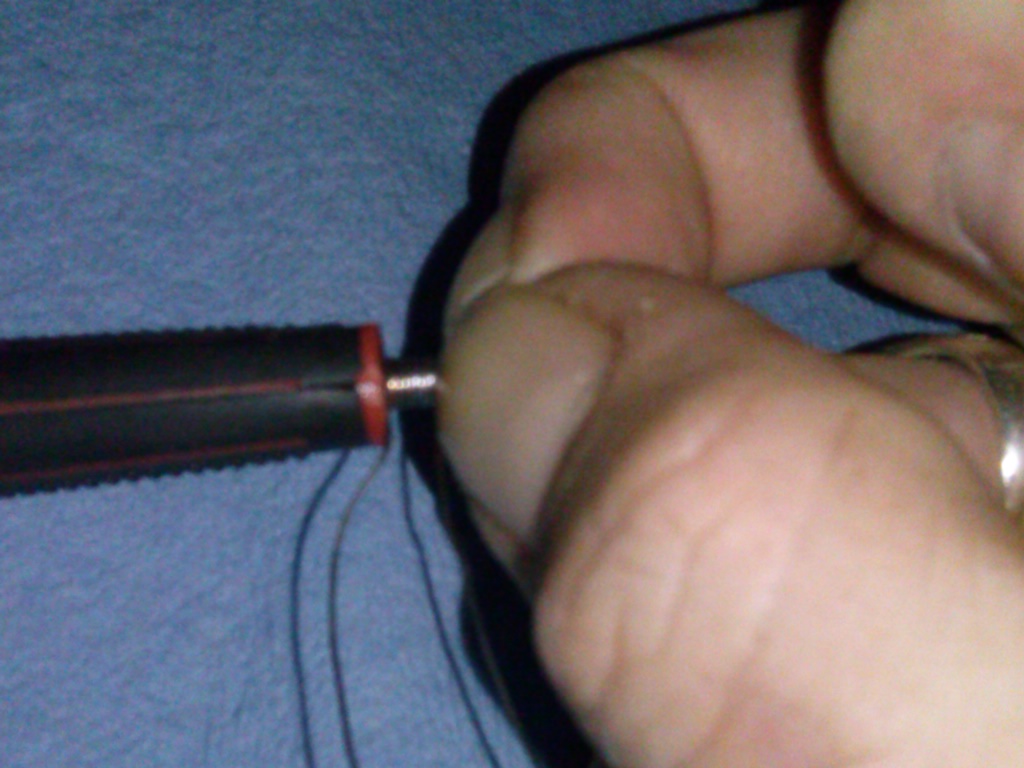

So, grab your 28ga wire and your cutting tool of choice and measure out about 3 1/4" (77mm). The extra length is for the leads to the posts and so you have some room to work with on the last wrap.

Now let's wrap that baby and start blowing clouds! Hang on just a second... got everything you need, including something to test that new coil? A regulated mod that can test resistance is OK, but if you are going to start playing around or are using a mechanical mod take the time to get a multimeter (about $20 @ Walmart) and learn to use it.

Now we can wrap that rascal!

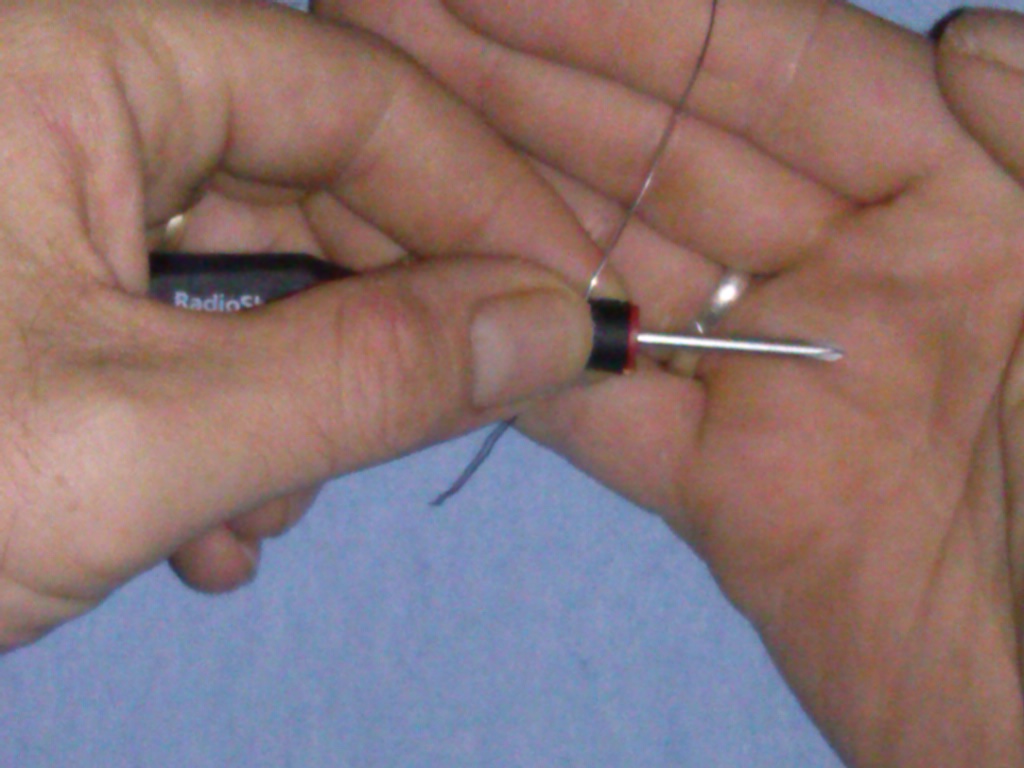

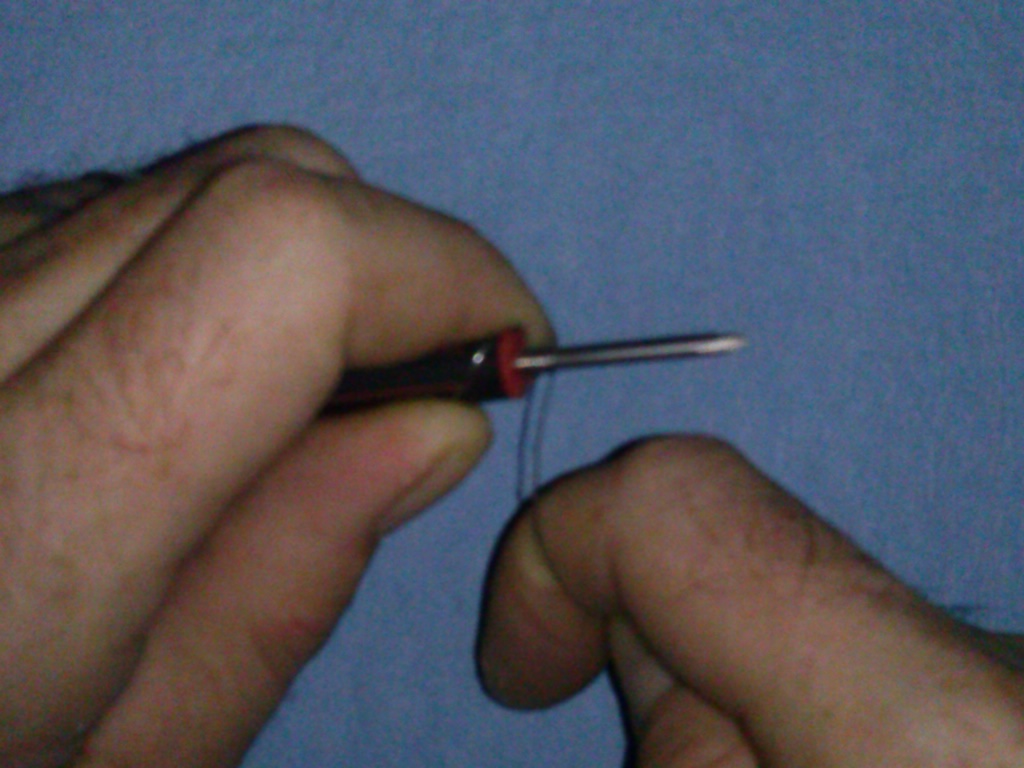

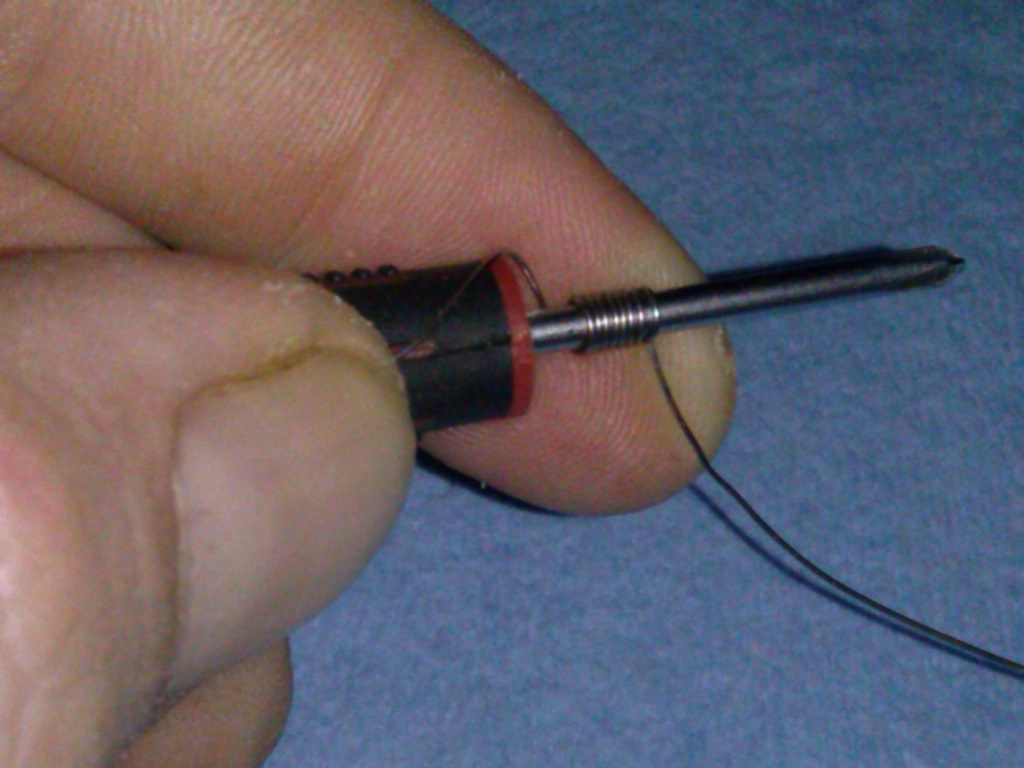

Grab your precision screwdriver/drill bit/Allen wrench/coiling jig and let's get to work. Leave about a quarter inch of a lead on the coil (the coil jig will take care of that for you as you trap the wire) and give it 8 wraps. Be sure to leave the leads on opposite sides because of the atty its going on, an RDA would have them on the same side (thus the 8/7 wrap).

Now all you have to do is mount and test your new coil. If it reads 1.2 ohms, or close to it, you're good to go. If not, let's figure out why.

Are your screws tight, did you wrap it on the right size mandrel, was the wire the right gauge & length? If all the answers are yes then you should be within a few tenths of an ohm, if you are way off that mark you may want to start over.

A more in-depth coil wrapping tutorial with many more views will be on my PIF thread for rebuildables (here) and on my ECF blog... with many many pictures!