Spent tonight vaping on a T3'D and wrote a review of it. Classic little clearo...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Spent tonight vaping on a T3'D and wrote a review of it. Classic little clearo...

A big improvement on the T3s. I had batches of the latter for testing coil build variations alongside PT and Mini. My favorite walk around to spare the growing collection of high end and other test gear. About the most stable clearo Kanger made with the original 510 config. Perfect vacuum temp balance and with the ample liquid supply it could last you forever. My favorite walk around was a 3Ts on the eGo 510 connect of the Magneto with 350's and a 12W kick. A pair of these on the day long errand mall runs did the job. Great flavor and vapor in fact perhaps better than the PT itself with factory or rebuilt cotton or Nextel. Great little devices and still keep a few around to test tobacco variants with ceramic alongside the PT and Mega. A great mellow rewarding cool vape a 8-12W.

Best thing I loved is the compact little kit and substantial production always seemed to evoke a lot of curiosity as I vaped publicly. And I always relish the opportunity to talk up vaping.

Good luck Shawn.

Last edited:

Lifted [with edits] from the thread post Why can't we tension before we wind?

Why can't we tension before we wind?

How much strain are you applying to the wire?

Wire straighteners also make wire stick straight. Coils wound with straightened wire [then formed] can gain a lot of symmetry. Even hand winds. Are they tight enough to oxidize in a state of adhesion?

...we've known for ever that wire separations in a contact coil can cause vape temperatures to go up...If done correctly, they [leads] impart just enough tension to maintain end turn adhesion and congruity…Geometry and orientation do matter.

Any res wire you connect in a DC neg/pos circuit is going to work, to fire. That's not the discussion here. And I'm not talking here to get folks to wind parallels. It's an exercise to demonstrate what strain does at the molecular level to assist in completing a microcoil. All wires have strain and we add strain. My contribution has been to foster an understanding of how to manage it to specific ends. And this includes adapting strain towards density or dispersion, better said, the balance we prefer. Ideally we should know what optimal is in practical terms. That's my goal here. Disseminating that approach to rebuilding.

Firing from inside out is what all coils do. That is not temperature uniformity.

Not trying to be contentious but contact coils are shorts. Always have been. They go hot in operation as any short does. The only way we have of making a complete circuit out of this is to ensure as complete oxidation as practicable. The magic comes the first time we manage to torch and compress a wind tight enough to get that without having first carbonized the wire too much. Unfortunately, that method was unpredictable and unreliable except that it got a good number of coils into adhesion and impressively behaving like a complete circuit. Then the concentrated geometry exhibits the potential for the effect, an more even distribution of heat flux (if consistently oxidized).

As contact and oxidation uniformity improves tensioned microcoils evidence first a decentralized color temperature in operation with heat building less focally than a conventional coil (click image below). This is seen once the coil stabilizes in temp as indicated by the following video. The interesting thing is the stabilization of color temperature as the element is fired, not increasingly a central heat from inside out. Further, a predictable consistency from wind to wind. That is not what happens in a common coil.

The more stable the build, the more stable the wire color temperature, as predicted by the physics.

That's what this discussion is about. Completing the circuit for what is otherwise a short.

Good luck.

Why can't we tension before we wind?

How much strain are you applying to the wire?

Wire straighteners also make wire stick straight. Coils wound with straightened wire [then formed] can gain a lot of symmetry. Even hand winds. Are they tight enough to oxidize in a state of adhesion?

...we've known for ever that wire separations in a contact coil can cause vape temperatures to go up...If done correctly, they [leads] impart just enough tension to maintain end turn adhesion and congruity…Geometry and orientation do matter.

Any res wire you connect in a DC neg/pos circuit is going to work, to fire. That's not the discussion here. And I'm not talking here to get folks to wind parallels. It's an exercise to demonstrate what strain does at the molecular level to assist in completing a microcoil. All wires have strain and we add strain. My contribution has been to foster an understanding of how to manage it to specific ends. And this includes adapting strain towards density or dispersion, better said, the balance we prefer. Ideally we should know what optimal is in practical terms. That's my goal here. Disseminating that approach to rebuilding.

Firing from inside out is what all coils do. That is not temperature uniformity.

Not trying to be contentious but contact coils are shorts. Always have been. They go hot in operation as any short does. The only way we have of making a complete circuit out of this is to ensure as complete oxidation as practicable. The magic comes the first time we manage to torch and compress a wind tight enough to get that without having first carbonized the wire too much. Unfortunately, that method was unpredictable and unreliable except that it got a good number of coils into adhesion and impressively behaving like a complete circuit. Then the concentrated geometry exhibits the potential for the effect, an more even distribution of heat flux (if consistently oxidized).

As contact and oxidation uniformity improves tensioned microcoils evidence first a decentralized color temperature in operation with heat building less focally than a conventional coil (click image below). This is seen once the coil stabilizes in temp as indicated by the following video. The interesting thing is the stabilization of color temperature as the element is fired, not increasingly a central heat from inside out. Further, a predictable consistency from wind to wind. That is not what happens in a common coil.

The more stable the build, the more stable the wire color temperature, as predicted by the physics.

That's what this discussion is about. Completing the circuit for what is otherwise a short.

Good luck.

Last edited:

I see this thread has been frequented for about two years. Did the original poster ever get a definitive answer to his question. I've noticed alot of ECF people will misdirect just about any question asked. They will throw everything in the book at you, except for what the amswers you were seeking.

I have a project in mind a simple 1.8 ohm - dual- horizontal coil for protank 3. I will be using these materials; 2.mm silica wick and 30ag kanthal round wire. What I want to know is, how many wraps will I need to make around each coil in order to achieve the target resistance. I'm going to be wrapping tight coils btw.

I have a project in mind a simple 1.8 ohm - dual- horizontal coil for protank 3. I will be using these materials; 2.mm silica wick and 30ag kanthal round wire. What I want to know is, how many wraps will I need to make around each coil in order to achieve the target resistance. I'm going to be wrapping tight coils btw.

I see this thread has been frequented for about two years. Did the original poster ever get a definitive answer to his question. I've noticed alot of ECF people will misdirect just about any question asked. They will throw everything in the book at you, except for what the amswers you were seeking.

I have a project in mind a simple 1.8 ohm - dual- horizontal coil for protank 3. I will be using these materials; 2.mm silica wick and 30ag kanthal round wire. What I want to know is, how many wraps will I need to make around each coil in order to achieve the target resistance. I'm going to be wrapping tight coils btw.

...but I'm typing this, to try and find out what works best when building an MC (microcoil) for the Protank.

Think the OP (a good friend of mine) got his (above) question answered but he had to start with what a m.c. "is", what it can do and how to get there. I think he may have experimented with verticals himself and posted impressions here. Also here are links to a PT dedicated thread on verticals that ran for over a year.

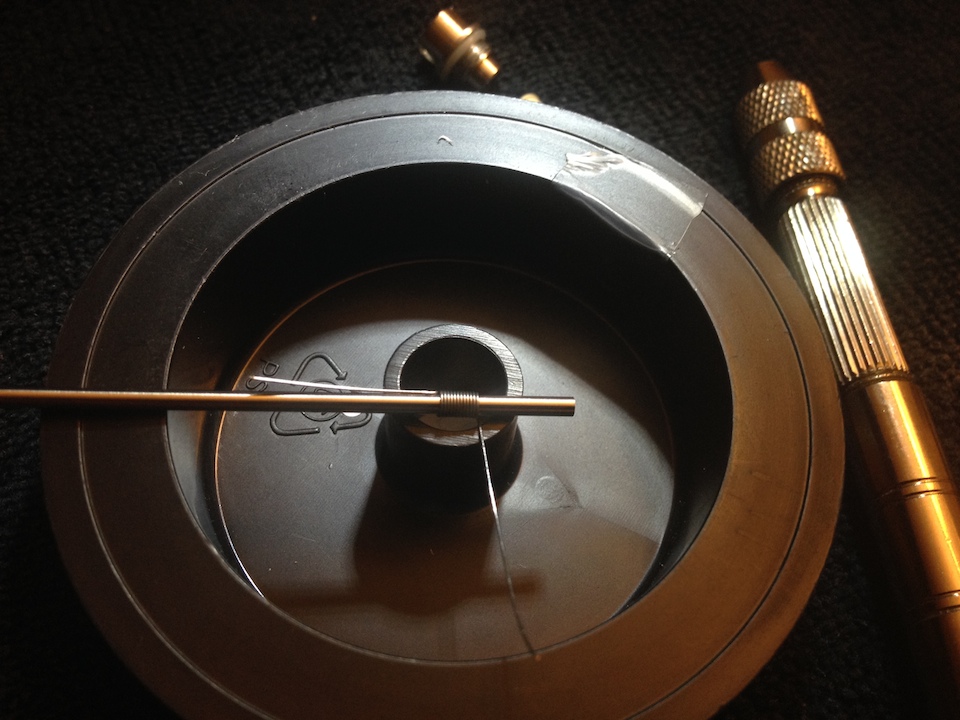

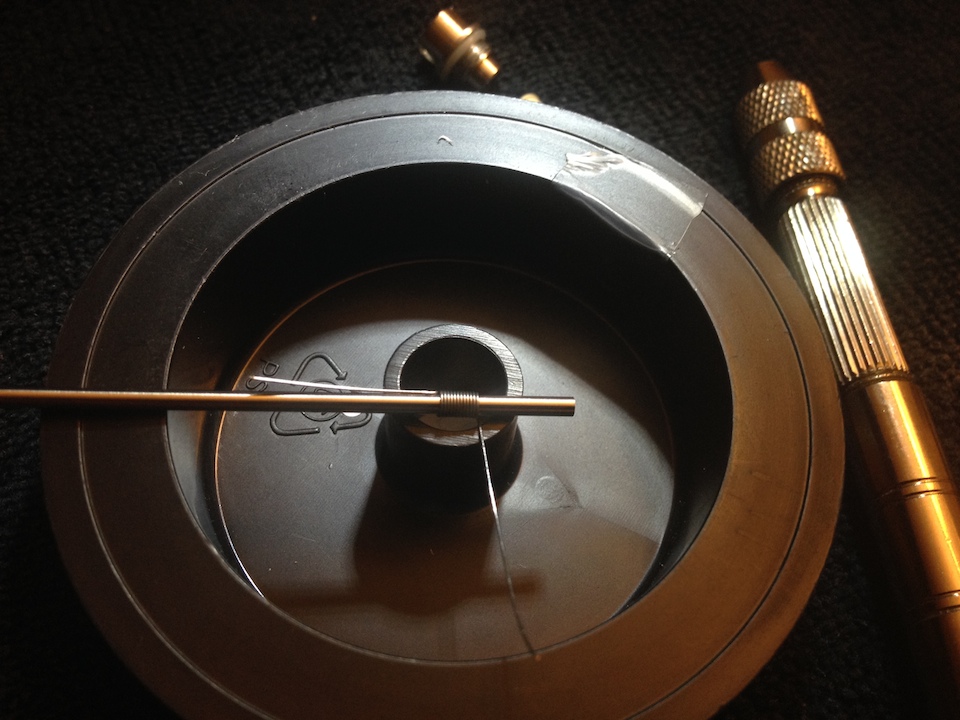

I introduced the tensioned microcoil on this thread and if you're after perfecting a Kanthal coil you came to the right place. Still enjoy some of my fav tobacco in a Protank Mega running straight wire 28AWG which is more than adequate for the airflow or a high contact area horizontal twisted center lead dual coil (@1.8mm Ø) like this one…

I can tell ya having built more than a few of these that throwing a lot of wire into a Protank is utterly useless unless you can make the wind efficient as well as powerful. Vapor dispersion (heat expansion) quickly shuts down output. There's not enough airflow to support airy builds. That's exactly what verticals are. When production is highly concentrated and excess heating to air limited the Protank can be a thoroughly enjoyable vape at around 17.5W, 1.5Ω>.

If you'd like to discover how to get that kind of density out of the small atomizer that a PT head is maxing out on limited airflow…you definitely landed on the right thread. And once you have those tools in your belt bro you can do it anywhere on anything.

Just post when you're ready. If somebody doesn't pick it up, I'll be glad to help.

Good luck D.

Think the OP (a good friend of mine) got his (above) question answered but he had to start with what a m.c. "is", what it can do and how to get there. I think he may have experimented with verticals himself and posted impressions here. Also here are links to a PT dedicated thread on verticals that ran for over a year.

I introduced the tensioned microcoil on this thread and if you're after perfecting a Kanthal coil you came to the right place. Still enjoy some of my fav tobacco in a Protank Mega running straight wire 28AWG which is more than adequate for the airflow or a high contact area horizontal twisted center lead dual coil (@1.8mm Ø) like this one…

I can tell ya having built more than a few of these that throwing a lot of wire into a Protank is utterly useless unless you can make the wind efficient as well as powerful. Vapor dispersion (heat expansion) quickly shuts down output. There's not enough airflow to support airy builds. That's exactly what verticals are. When production is highly concentrated and excess heating to air limited the Protank can be a thoroughly enjoyable vape at around 17.5W, 1.5Ω>.

If you'd like to discover how to get that kind of density out of the small atomizer that a PT head is maxing out on limited airflow…you definitely landed on the right thread. And once you have those tools in your belt bro you can do it anywhere on anything.

Just post when you're ready. If somebody doesn't pick it up, I'll be glad to help.

Good luck D.

Well I am going to need to rebuild my PT 3 coils soon. The two that came with it are going to burn out in a couple weeks and I want to have a couple coiled wicks ready to replace them.

I vape with my iStick 30w and my pt 3 around 4.0 - 4.2v. I notice if I go upwards of 4.4 I get a real nasty burnt taste. I vape an 80/20 Vg dominant blend.

I'm thinking that maybe building a single mc @ 1.5 - 1.8 ohms, using 30awg kanthal round wire would be a good place to start. I have no experience whatsoever with rebuilding. A horizontal mc is what I have in mind. I can't seem to get a great airflow with this tank so A vertical coil is not an option. I don't wanna burn any o-rings.

What are your thoughts on the materials I should use and how to get to my target coil res?

Hey D and thanks for the update on your sit. Same mess that got me into this pickle. LOL

The coil's the thing D. Hit that and 90% of the issues that arise are far easier to diagnose and correct.

Look, two things you should know. It's easy to build a microcoil (touching coil) because it's seconds to roll 'em out on a pin vise (see below). The symmetry matters to keep them from shorting. Wire most used is Kanthal, an aluminum alloy. When pulsed it builds an "alumina" layer on its surface (insulation, as in any electrical wire). Important here because where getting the wires to touch (short). If that happens and there's no surface insulation, the wire can go very hot. A lot hotter than the resistance would normally allow. That won't get you a good vape because what we want is vaporization, not excess heat vented to air. And that layer is ceramic which isolates the metal from your vape to boot. That's the sum up.

You'll need a pin vise (<10$), some common drill bits and a coil of wire to start (as pictured below). Unless you want or need to wind on 1/16" prolly going to need to shop for some 1.778mm drill blanks (bits) and sources are noted in earlier posts. That is the largest diameter you can get in the PT3 head and will get you the thickest wick possible as we're going to use the bit to stabilize the wind. The same method (of localizing exact diameters) that Kanger ultimately adopted in making the current Subtank OCC heads…was being done right here on this thread and the preceding Protank cotton thread since 2013. Organic cotton from CVS, etc. will do for starters on the wick.

Small investment and we can get you winding stuff in a few days (typical) that it used to take weeks and months to tweak. So search pin vise on this thread and you should turn up a bunch of links with the description you should look for (brass pin vise) or google it. As you get that in the work we can talk about steam-engine.com and how to select temperature and surface area goals for your tastes. You like it a bit on the warm side at 1.5 and a tensioned micro which you'll build will vape denser than a standard coil so cooler. That said, you'll probably be a bit better off at 29guage and 9-turns should keep you just under 1.6Ω, 10-turns just over 1.7 and you a happy camper.

Certainly possible to build verticals in a PT. I use them extensively in drippers but in a tank atty assembly with cotton external wicking they tend to concentrate juice at the bottom (or leak) and dry out and get hot at the top of the coil. There are ways to address that but we're talking an advanced build. First thing we all need to learn to nail on the head is…keep the coil from shorting. That means in terms of the wind and also training your muscles for that and the mechanics of installation. Process should probably be second nature to you within a couple of weeks. Didn't use to be that but let me tell you the instructions are here proven by hundreds of participants over two years as you'll see. And the idea behind the mechanics will certainly aid your understanding of how to duplicate the result everywhere.

Which of the airflow bases do you have? You eventually will need the v3 for the coil we'll be building.

Let me know when you're ready or post here on any question.

Good luck D.

The coil's the thing D. Hit that and 90% of the issues that arise are far easier to diagnose and correct.

Look, two things you should know. It's easy to build a microcoil (touching coil) because it's seconds to roll 'em out on a pin vise (see below). The symmetry matters to keep them from shorting. Wire most used is Kanthal, an aluminum alloy. When pulsed it builds an "alumina" layer on its surface (insulation, as in any electrical wire). Important here because where getting the wires to touch (short). If that happens and there's no surface insulation, the wire can go very hot. A lot hotter than the resistance would normally allow. That won't get you a good vape because what we want is vaporization, not excess heat vented to air. And that layer is ceramic which isolates the metal from your vape to boot. That's the sum up.

You'll need a pin vise (<10$), some common drill bits and a coil of wire to start (as pictured below). Unless you want or need to wind on 1/16" prolly going to need to shop for some 1.778mm drill blanks (bits) and sources are noted in earlier posts. That is the largest diameter you can get in the PT3 head and will get you the thickest wick possible as we're going to use the bit to stabilize the wind. The same method (of localizing exact diameters) that Kanger ultimately adopted in making the current Subtank OCC heads…was being done right here on this thread and the preceding Protank cotton thread since 2013. Organic cotton from CVS, etc. will do for starters on the wick.

Small investment and we can get you winding stuff in a few days (typical) that it used to take weeks and months to tweak. So search pin vise on this thread and you should turn up a bunch of links with the description you should look for (brass pin vise) or google it. As you get that in the work we can talk about steam-engine.com and how to select temperature and surface area goals for your tastes. You like it a bit on the warm side at 1.5 and a tensioned micro which you'll build will vape denser than a standard coil so cooler. That said, you'll probably be a bit better off at 29guage and 9-turns should keep you just under 1.6Ω, 10-turns just over 1.7 and you a happy camper.

Certainly possible to build verticals in a PT. I use them extensively in drippers but in a tank atty assembly with cotton external wicking they tend to concentrate juice at the bottom (or leak) and dry out and get hot at the top of the coil. There are ways to address that but we're talking an advanced build. First thing we all need to learn to nail on the head is…keep the coil from shorting. That means in terms of the wind and also training your muscles for that and the mechanics of installation. Process should probably be second nature to you within a couple of weeks. Didn't use to be that but let me tell you the instructions are here proven by hundreds of participants over two years as you'll see. And the idea behind the mechanics will certainly aid your understanding of how to duplicate the result everywhere.

Which of the airflow bases do you have? You eventually will need the v3 for the coil we'll be building.

Let me know when you're ready or post here on any question.

Good luck D.

Last edited:

Hey D and thanks for the update on your sit. Same mess that got me into this pickle. LOL

The coil's the thing D. Hit that and 90% of the issues that arise are far easier to diagnose and correct.

Look, two things you should know. It's easy to build a microcoil (touching coil) because it's seconds to roll 'em out on a pin vise (see below). The symmetry matters to keep them from shorting. Wire most used is Kanthal, an aluminum alloy. When pulsed it builds an "alumina" layer on its surface (insulation, as in any electrical wire). Important here because where getting the wires to touch (short). If that happens and there's no surface insulation, the wire can go very hot. A lot hotter than the resistance would normally allow. That won't get you a good vape because what we want is vaporization, not excess heat vented to air. And that layer is ceramic which isolates the metal from your vape to boot. That's the sum up.

You'll need a pin vise (<10$), some common drill bits and a coil of wire to start (as pictured below). Unless you want or need to wind on 1/16" prolly going to need to shop for some 1.778mm drill blanks (bits) and sources are noted in earlier posts. That is the largest diameter you can get in the PT3 head and will get you the thickest wick possible as we're going to use the bit to stabilize the wind. The same method (of localizing exact diameters) that Kanger ultimately adopted in making the current Subtank OCC heads…was being done right here on this thread and the preceding Protank cotton thread since 2013. Organic cotton from CVS, etc. will do for starters on the wick.

Small investment and we can get you winding stuff in a few days (typical) that it used to take weeks and months to tweak. So search pin vise on this thread and you should turn up a bunch of links with the description you should look for (brass pin vise) or google it. As you get that in the work we can talk about steam-engine.com and how to select temperature and surface area goals for your tastes. You like it a bit on the warm side at 1.5 and a tensioned micro which you'll build will vape denser than a standard coil so cooler. That said, you'll probably be a bit better off at 29guage and 9-turns should keep you just under 1.6Ω, 10-turns just over 1.7 and you a happy camper.

Certainly possible to build verticals in a PT. I use them extensively in drippers but in a tank atty assembly with cotton external wicking they tend to concentrate juice at the bottom (or leak) and dry out and get hot at the top of the coil. There are ways to address that but we're talking an advanced build. First thing we all need to learn to nail on the head is…keep the coil from shorting. That means in terms of the wind and also training your muscles for that and the mechanics of installation. Process should probably be second nature to you within a couple of weeks. Didn't use to be that but let me tell you the instructions are here proven by hundreds of participants over two years as you'll see. And the idea behind the mechanics will certainly aid your understanding of how to duplicate the result everywhere.

Which of the airflow bases do you have? You eventually will need the v3 for the coil we'll be building.

Let me know when you're ready or post here on any question.

Good luck D.

Sorry to be so short with the reply in advance.

Can I purchase organic cotton at walgreens? The closest CVS here in northern nevada is a half hour away. I'd be spending more in gas than on the actual cotton lol. I do have a protank 3 btw. I think it's fake though. The scratch off code returned the result that my authentification # has already been checked over 250 times previously. I guess that's not too important, as I can just break down these 2 ohm coils that came with the tank and try my best to build them in a better fashion.

I'm sorry but your attaches images will not load for me. I think I may have to check this on my laptop instead of my ancient iphone 4.

I still have to order the wire...would you suggest 30awg kanthal for a 1.8 ohm coil?

p.s. I guess this reply wasn't so short afterall.

I goggled "organic cotton at Walgreens" and it says you can. I would just make sure the label says 100% cotton. As for the wire question I use 30 gauge and love that but I have heard others use 29.Sorry to be so short with the reply in advance.

Can I purchase organic cotton at walgreens? The closest CVS here in northern nevada is a half hour away. I'd be spending more in gas than on the actual cotton lol. I do have a protank 3 btw. I think it's fake though. The scratch off code returned the result that my authentification # has already been checked over 250 times previously. I guess that's not too important, as I can just break down these 2 ohm coils that came with the tank and try my best to build them in a better fashion.

I'm sorry but your attaches images will not load for me. I think I may have to check this on my laptop instead of my ancient iphone 4.

I still have to order the wire...would you suggest 30awg kanthal for a 1.8 ohm coil?

p.s. I guess this reply wasn't so short afterall.

I would also recommend the air flow control adapter for the Protank. Opens up a whole new world and is cheap (like 4-5 dollars) more air will help with not getting burning hits

Sorry to be so short with the reply in advance.

Can I purchase organic cotton at walgreens? The closest CVS here in northern nevada is a half hour away. I'd be spending more in gas than on the actual cotton lol. I do have a protank 3 btw. I think it's fake though. The scratch off code returned the result that my authentification # has already been checked over 250 times previously. I guess that's not too important, as I can just break down these 2 ohm coils that came with the tank and try my best to build them in a better fashion.

I'm sorry but your attaches images will not load for me. I think I may have to check this on my laptop instead of my ancient iphone 4.

I still have to order the wire...would you suggest 30awg kanthal for a 1.8 ohm coil?

p.s. I guess this reply wasn't so short afterall.

Sorry about that. We all get a dud from time to time. Aftermarket head assemblies should be ok. If the threading is bad it may leak worse than the factory. All 510's leak btw. We try to make an efficient coil so that they actually vaporize. Novel idea. Best chance to avert over-saturation (insufficient power to wick).

Not sure if you were referring to my image/s.

Glad channel was able to pick up. Holler if you need us.

Good luck!

p.s. And post picks if you can. Don't be bashful (I use an iPhone 4S). I know, I know, retro.

Re: The end of microcoils?

Y'all might want to look at Dr. Farsalinos' interview regarding his recently completed study's findings.

An advanced somewhat technical discussion, I am extremely pleased to see some very knowledgeable folks speak out regarding some of Dr. Farsalinos' more controversial remarks on the thread, LOL...The end of microcoils?

I'm most concerned as well that the specifications of the vaporizing element itself weren't clearly defined…in a scientific study about vaporization. With all this talk of metals, torching, dry firing being bad what the heck are we talkin' about? But hey, that's just me. My most recent contribution there...

Y'all might want to look at Dr. Farsalinos' interview regarding his recently completed study's findings.

An advanced somewhat technical discussion, I am extremely pleased to see some very knowledgeable folks speak out regarding some of Dr. Farsalinos' more controversial remarks on the thread, LOL...The end of microcoils?

I'm most concerned as well that the specifications of the vaporizing element itself weren't clearly defined…in a scientific study about vaporization. With all this talk of metals, torching, dry firing being bad what the heck are we talkin' about? But hey, that's just me. My most recent contribution there...

Nor can we discern that from this interview with Dr. Farsalinos. It is unclear to me how any metal off-gassing could bypass a uniform A2O3 deposition of Kanthal. That would infer that the alumina is being compromised at extremely low temp's (contrary to its specs). Considering that in normal operation (no hot spots, or exposed wire) of a properly oxidized KA1 wind vaporization should stabilize at/below transition temperature as long as the wind is thermally stable and there is adequate transfer to product flow.

A thermally stable wind is what would then be indicated? No?

Kanthal was designed as a heating element. Its oxidation ensures its durability and resistance to corrosion. As acknowledged by Dr. Fasalinos ceramic insulates (isolates) the base metal/s deterring metallic oxidation of the vaped product. Such a wire/wind not properly oxidized would then exhibit all the primary metal exposure as the alternatives, to both product and the airstream.

So shouldn't we be pulse-annealing all our Kanthal winds in lieu of torching? To properly optimize the winds thermal effectiveness, stability and for the presumptive safety reasons concerning metallic exposure.

Instead it's inferred we shouldn't be torching our coils at all without an alternative. For Kanthal, relegating it to the same potentials of metallic exposure as every other wire variant. I'm not dispensing with the utility of the latter merely pointing out the difference in potentials for KA1's best use.

My reasoning then would be that Kanthal was not used or considered. And not cited per any summaries I've seen yet. Then you're right we don't know what metals are being referred to. And if the coil is what remains "one of the big unknowns" why not address that first and foremost.

I agree with you AT we need to oxidize KA1 and a simple process we all need.

Good luck.

Last edited:

Sorry about that. We all get a dud from time to time. Aftermarket head assemblies should be ok. If the threading is bad it may leak worse than the factory. All 510's leak btw. We try to make an efficient coil so that they actually vaporize. Novel idea. Best chance to avert over-saturation (insufficient power to wick).

Not sure if you were referring to my image/s.

Glad channel was able to pick up. Holler if you need us.

Good luck!

p.s. And post picks if you can. Don't be bashful (I use an iPhone 4S). I know, I know, retro.

Yeah I've noticed the leakage.

How concerned should I be about it? It seems its more condensation than actual juice dripping onto the battery pin. I clean it out with a rolled up piece of toilet paper every time I refill my tank. It's almost like tiny dew droplets get in there. The threading seems fine...it doesn't cross thread at all which is great. Cross threading is the worst!!! I'm going to keep my pt3 but was also looking at a subtank nano, but a daunting feeling came over me when I saw what the coils look like. Seems like a difficult build for a beginner like myself.

Its Chanel, like the fine handbag. The other is a station on the television, or a pair of lockable pliersGlad channel was able to pick up. Holler if you need us

Very informative thread thanks for the tips from everyone.

I was using mpt2's exclusively for about a year now and my usual build was a 6 wrap tmc 5/64 bit 32 kanthal twisted usually came to 1.6 ohms. Since I have got the stm have been spoiled by airflow and mpt wasn't cutting it anymore so I modded it as follows.

Coil chimney stem drilled out with 7/64 bit.

Coil center pin drilled with 5/64 (most tedious step)

Coil base drilled where the flange and threads meet with 1/16. 4 holes spaced as evenly as possible.

Also the mpt bottom base drilled out the small airflow holes with 5/64

Build I use for this setup is 5 spaced wraps of 32 twisted kanthal around 1/16 bit wicked with rayon snipped very close to juice channels. Usually comes to 1.2 ohms. I find the spaced wraps in a set up like this helps to alleviate gunking.

It works very well vaping at 12 watts. Getting a nice steady lung inhale with no dry hits and decent vaper.

I know this is a micro coil thread aand I appologize that the build is spaced but it has just been working so well for me that I wanted to share.

ETA heh I know the mpt doesnt hold much juice but I used to vape 18 nic and now do 3 on the stm and find about 9 on the mpt is the sweet spot. Vaping higher nic on the mpt I dont vape as much and the tank lasts a little while, probably longer than a tank on the stm. I love the mpt I will definitely be using it until its worn right out which will be quite a while with the right up keep because they are a quality built tank.

Cheers

I was using mpt2's exclusively for about a year now and my usual build was a 6 wrap tmc 5/64 bit 32 kanthal twisted usually came to 1.6 ohms. Since I have got the stm have been spoiled by airflow and mpt wasn't cutting it anymore so I modded it as follows.

Coil chimney stem drilled out with 7/64 bit.

Coil center pin drilled with 5/64 (most tedious step)

Coil base drilled where the flange and threads meet with 1/16. 4 holes spaced as evenly as possible.

Also the mpt bottom base drilled out the small airflow holes with 5/64

Build I use for this setup is 5 spaced wraps of 32 twisted kanthal around 1/16 bit wicked with rayon snipped very close to juice channels. Usually comes to 1.2 ohms. I find the spaced wraps in a set up like this helps to alleviate gunking.

It works very well vaping at 12 watts. Getting a nice steady lung inhale with no dry hits and decent vaper.

I know this is a micro coil thread aand I appologize that the build is spaced but it has just been working so well for me that I wanted to share.

ETA heh I know the mpt doesnt hold much juice but I used to vape 18 nic and now do 3 on the stm and find about 9 on the mpt is the sweet spot. Vaping higher nic on the mpt I dont vape as much and the tank lasts a little while, probably longer than a tank on the stm. I love the mpt I will definitely be using it until its worn right out which will be quite a while with the right up keep because they are a quality built tank.

Cheers

Last edited:

Its Chanel, like the fine handbag. The other is a station on the television, or a pair of lockable pliers

Yes you are! Fine that is. Mea culpa. Enjoy and good luck.

Last edited:

Very informative thread thanks for the tips from everyone.

I was using mpt2's exclusively for about a year now and my usual build was a 6 wrap tmc 5/64 bit 32 kanthal twisted usually came to 1.6 ohms. Since I have got the stm have been spoiled by airflow and mpt wasn't cutting it anymore so I modded it as follows.

Coil chimney stem drilled out with 7/64 bit.

Coil center pin drilled with 5/64 (most tedious step)

Coil base drilled where the flange and threads meet with 1/16. 4 holes spaced as evenly as possible.

Also the mpt bottom base drilled out the small airflow holes with 5/64

Build I use for this setup is 5 spaced wraps of 32 twisted kanthal around 1/16 bit wicked with rayon snipped very close to juice channels. Usually comes to 1.2 ohms. I find the spaced wraps in a set up like this helps to alleviate gunking.

It works very well vaping at 12 watts. Getting a nice steady lung inhale with no dry hits and decent vaper.

I know this is a micro coil thread aand I appologize that the build is spaced but it has just been working so well for me that I wanted to share.

ETA heh I know the mpt doesnt hold much juice but I used to vape 18 nic and now do 3 on the stm and find about 9 on the mpt is the sweet spot. Vaping higher nic on the mpt I dont vape as much and the tank lasts a little while, probably longer than a tank on the stm. I love the mpt I will definitely be using it until its worn right out which will be quite a while with the right up keep because they are a quality built tank.

Cheers

Welcome. No worries. This is a smorgasbord and we will get to the great vape eventually. Let us know when you're ready to ditch the appetizers!

Good luck.

Hey MacTechVpr!

I'm on MVS right now looking at a subtank nano...

Should I buy it? It says minimum draw required to fire the coils is 15W. I like the battery life I get with my current set-up.

How much of a blow will my battery life take if I start sub-ohming?

I'm on MVS right now looking at a subtank nano...

Should I buy it? It says minimum draw required to fire the coils is 15W. I like the battery life I get with my current set-up.

How much of a blow will my battery life take if I start sub-ohming?

lol come on now be fair the mpt is great to use for higher nics that would otherwise make me gag if I tried to deep lung inhale no? I find it a great alternative and the build I mentioned works very well.Welcome. No worries. This is a smorgasbord and we will get to the great vape eventually. Let us know when you're ready to ditch the appetizers!

Good luck.

lol come on now be fair the mpt is great to use for higher nics that would otherwise make me gag if I tried to deep lung inhale no? I find it a great alternative and the build I mentioned works very well.

Dude, who ya talkin' at? I'm the tootie puffer professor here.

Hey MacTechVpr!

I'm on MVS right now looking at a subtank nano...

Should I buy it? It says minimum draw required to fire the coils is 15W. I like the battery life I get with my current set-up.

How much of a blow will my battery life take if I start sub-ohming?

Haven't bought or tried one yet. Can't find anyone vaping one! So I can't say what it vapes like but I suspect it's awesome with the right build. Been my experience slim tanks kick it on both flavor and production. You don't have the RBA option. But the OCC is very rebuildable. Easier in many respects than the prior Protank assemblies. So for those holding on to their Protanks, I have, it is a viable option for low wattage flavor. Again, with a density build which we know how to get right here.

Insofar as power, I've vaped 2.5mm and fat 2.78mm winds on the SubMini at 9W for a very satisfying cool vape. I've no doubt the Nano can as well. The increased airflow will make warmer temp's a lot more productive and palatable to a great many of us who enjoy the low-wattage spectrum.

If you think you might enjoy more this in future the Mini is a great platform.

Good luck D.

p.s. You may be able to find my pics earlier on the twisted lead parallels for the Subtank. Tensioned micro's in this tank are phenomenal. Excellent in a PT, outstanding with this much airflow. I'd say easily a 30% production difference over a standard coil BUT with an added richness of texture and flavor density the extremely airy factory builds lack. You'll just have to make one to see it.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 1

- Views

- 685

- Replies

- 3

- Views

- 984

- Locked

- Replies

- 6

- Views

- 3K

- Replies

- 1

- Views

- 579

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)