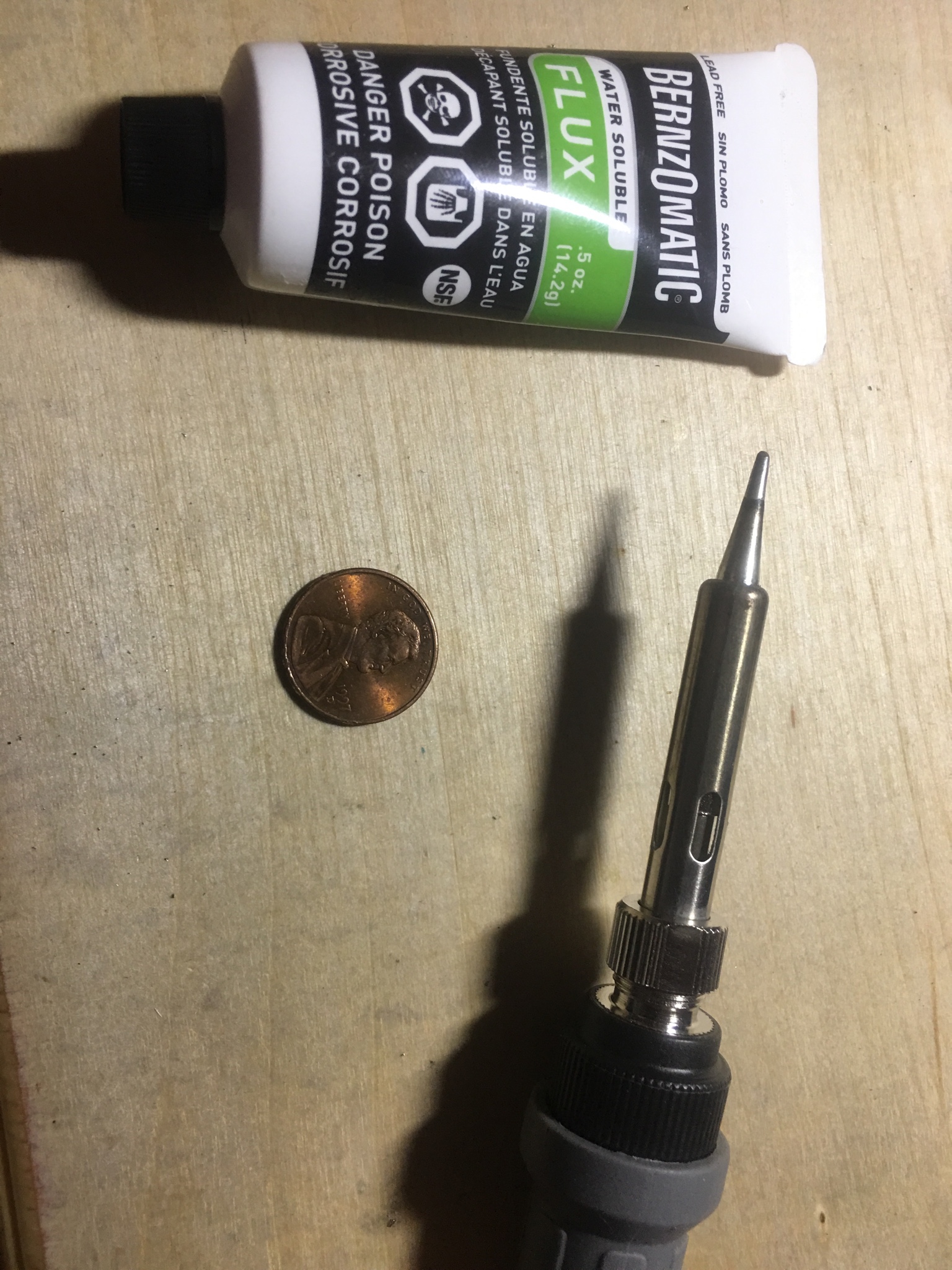

Don't even bother with rosin core solder, (IMO) it's too large and clumsy for small projects like this. Just get small gauge solder and separate flux. I build global marine distress signal systems all day and I can tell you that having a wet sponge on the deck of your soldering iron holder is the most efficient way to keep the tip clean and do a pretty job.

Don't scrimp on a cheapo soldering iron, you'll be sorry. Get one that has an external controller box and on\off switch. DO NOT get a soldering "gun" with the "pistol grip", precision soldering requires you to hold the iron like a pencil. I like small tips.

Stereoscopes are a good investment if you plan on soldering alot, you know, the magnified goggles? I use them for everything, not just surface mount soldering.

More heat and less contact time is better than less heat and more contact time. The latter is a good way to melt switches, chips, etc. or send a hot plasma wave through you whole circuit melting everything non-metallic.

As stated previously, tinning is the most efficient way to quickly solder components, use flux on bare wire first before tinning.

What temp do you solder at?

Sent from my iPhone using Tapatalk