I want to know what Chromium Oxides are forming on the different grades of SS and at what temperatures.

I do know that when heated above 710degF the chromium starts to oxidize preferentially. When doing hot work on SS it is common OSHA standard that when welding, cutting and heating SS, ventilation must be used to prevent Chromium Oxide inhalation. Inhalation is the primary entry for chromium oxides and Hexavalent chromium is recognized as a human carcinogen via inhalation.[2]

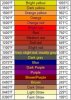

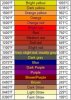

I am really hoping that the Chromium only reaches CRIII and not the more dangerous CR(V) and CR(VI). Based on the tutorials I have seen that heat the SS to glowing red 1500degF I am a bit worried . http://www.smex.net.au/reference/steelcolours.htm

. http://www.smex.net.au/reference/steelcolours.htm

-----------------------------------------

* Safety and Health Topics | Hexavalent Chromium

Hexavalent chromium can also be formed when performing "hot work" such as welding on stainless steel or melting chromium metal. In these situations the chromium is not originally hexavalent, but the high temperatures involved in the process result in oxidation that converts the chromium to a hexavalent state.

-----------------------------------------

* Ventilation and protection in welding, cutting and heating. - 1915.51

* http://doc.utwente.nl/69890/1/Langevoort87on.pdf

The oxidation rates of iron and chromium are of the same order of magnitude at

temperatures below 650 K (710 F). Subsequent oxidation results in an iron oxide on top of a chromium

oxide layer. At temperatures above 650 K the metal surface becomes enriched in chromium, which

is preferentially oxidized at these temperatures and pressures. Even prolonged oxidation does not

result in an iron-rich oxide surface. Nickel has never been found in its oxidized form. The binding

energy of oxygen, in the various oxide layers, is independent of the extent of oxidation and is

530.6 eV

*

The truth is I don't know. If anyone has done testing to see if the Chromium Oxides are contaminating the e-liquid we are inhaling I would like to know.

I have several samples that I am going to have tested by a independent lab. I will post the results of those tests here.

If anyone else does the same please post the results here.

If anyone has or finds research that would help please post it here.

Sincerely,

Boden

I do know that when heated above 710degF the chromium starts to oxidize preferentially. When doing hot work on SS it is common OSHA standard that when welding, cutting and heating SS, ventilation must be used to prevent Chromium Oxide inhalation. Inhalation is the primary entry for chromium oxides and Hexavalent chromium is recognized as a human carcinogen via inhalation.[2]

I am really hoping that the Chromium only reaches CRIII and not the more dangerous CR(V) and CR(VI). Based on the tutorials I have seen that heat the SS to glowing red 1500degF I am a bit worried

. http://www.smex.net.au/reference/steelcolours.htm

. http://www.smex.net.au/reference/steelcolours.htm

-----------------------------------------

* Safety and Health Topics | Hexavalent Chromium

Hexavalent chromium can also be formed when performing "hot work" such as welding on stainless steel or melting chromium metal. In these situations the chromium is not originally hexavalent, but the high temperatures involved in the process result in oxidation that converts the chromium to a hexavalent state.

-----------------------------------------

* Ventilation and protection in welding, cutting and heating. - 1915.51

Welding, cutting or heating of metals of toxic significance.

1915.51(d)(1)Welding, cutting or heating in any enclosed spaces aboard the vessel involving the metals specified below shall be performed with either general mechanical or local exhaust ventilation meeting the requirements of paragraph (b) of this section:

1915.51(d)(1)(i)Zinc-bearing base or filler metals or metals coated with zinc-bearing materials.

1915.51(d)(1)(ii)Lead base metals.

1915.51(d)(1)(iii)Cadmium-bearing filler materials.

1915.51(d)(1)(iv)Chromium-bearing metals or metals coated with chromium-bearing materials.

1915.51(d)(2)Welding, cutting or heating in any enclosed spaces aboard the vessel involving the metals specified below shall be performed with local exhaust ventilation in accordance with the requirements of paragraph (b) of this section or employees shall be protected by air line respirators in accordance with the requirements of § 1915.154:

--------------------------------------* http://doc.utwente.nl/69890/1/Langevoort87on.pdf

The oxidation rates of iron and chromium are of the same order of magnitude at

temperatures below 650 K (710 F). Subsequent oxidation results in an iron oxide on top of a chromium

oxide layer. At temperatures above 650 K the metal surface becomes enriched in chromium, which

is preferentially oxidized at these temperatures and pressures. Even prolonged oxidation does not

result in an iron-rich oxide surface. Nickel has never been found in its oxidized form. The binding

energy of oxygen, in the various oxide layers, is independent of the extent of oxidation and is

530.6 eV

*

The truth is I don't know. If anyone has done testing to see if the Chromium Oxides are contaminating the e-liquid we are inhaling I would like to know.

I have several samples that I am going to have tested by a independent lab. I will post the results of those tests here.

If anyone else does the same please post the results here.

If anyone has or finds research that would help please post it here.

Sincerely,

Boden