I think the RM7 is a rogue

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tensioned Micro Coils. The next step.

- Thread starter super_X_drifter

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

Is that a derringer?

Yes. It. Is.Is that a derringer?

My good friend Jon Kuroyama invented the Kuro coiler, the ones you've pictured look like the clones, I've handled many of the many available clones and the tolerances are pretty bad...with an authentic one you might achieve an even tighter coil.

Yeah man, they ain't kuro coilers. They are coil masters. Perfectly satisfied with them. And they were freeMy good friend Jon Kuroyama invented the Kuro coiler, the ones you've pictured look like the clones, I've handled many of the many available clones and the tolerances are pretty bad...with an authentic one you might achieve an even tighter coil.

My good friend Jon Kuroyama invented the Kuro coiler, the ones you've pictured look like the clones, I've handled many of the many available clones and the tolerances are pretty bad...with an authentic one you might achieve an even tighter coil.

Hi Tru--I have a question, since Jon Kuroyama is your friend: what does he think about forming a wire (as the coilers do, without tension) vs building tensioned coils, which is strongly advocated in this thread?

Just curious...

PMYeah man, they ain't kuro coilers. They are coil masters. Perfectly satisfied with them. And they were free. I like authentic, solid mech mods but these little lightweight coil masters do exactly what I need them to do. But thanks for that lil tidbit bro

I doubt he's aware of this method or concept, I return to LA in a couple days and I'll put him on this thread and we'll find out.Hi Tru--I have a question, since Jon Kuroyama is your friend: what does he think about forming a wire (as the coilers do, without tension) vs building tensioned coils, which is strongly advocated in this thread?

Just curious...

I doubt he's aware of this method or concept, I return to LA in a couple days and I'll put him on this thread and we'll find out.

Now that would be a fascinating conversation...

I started making my coils just like everyone else--by wrapping my wire around a screwdriver.

) just to see what it does.

) just to see what it does.Russ, that makes me miss work and my Bulldog lol... also my Dodge Intrepid tricked out as a police interceptor.

Sweet ride Bro!

Sweet ride Bro!

Russ, that makes me miss work and my Bulldog lol... also my Dodge Intrepid tricked out as a police interceptor.

Sweet ride Bro!

Thank you brother

Hey everybody. Hope y'all havin' a great Memorial Day Weekend.

What stifles the vape?

Little thought experiment for you and your remarks should be interesting on this. What happens to airflow when temperature drives pressure up rapidly in our atomizers? When vapor pressure rises, does vaporization increase? Or does it get stifled? The definition is important here. Think of internal pressure as resistance. Does drawing harder then get more output? Or is it diminishing return?

And it doesn't much tell when we first fire it always. May vape great…for a while. Even a hot leg will give you great heat output, at first. Until the effect of the excess heat starts to impact surrounding connections (wire and posts) as well as juice and wick. We often get what was pretty in the video; until, we don't.

Now movin' on...

Lifted this image from imgur to illustrate what happens without strain. First the obvious, significant thermal output diff between the pair (at app low V). To the recently initiated this might be well, great even firing coil. When power is upped (longer pulse) what do you think will happen to the top one?

Let me share what I see and can surmise from the above.

Coils were wound by the same method. Likely, a tight hand wind. Poss, but less likely a coiler as suggested by the one symmetrical wind. It is very difficult to maintain diametrical concentricity with a hand wind without tension winding. When we hand tension it's common to see diff levels of strain applied for a wound pair. That we see here with the stepped coil (top, left). With hand wind or coiler they will both expand in diameter and separate laterally. We can't correct from the deviation from the wind diameter spec; but, it seems an attempt was made to correct for contact in part for the cooler coil (top, right) based on the slightly darker color (bottom, left). Yes, it was compressed. So was the other resulting in the stepping due to diameter eccentricity and over-tightening. So the user likely chose not to continue the effort with the coil (bottom, right) continuing to get hotter. Which meant having to leave the coils in a state of temperature imbalance.

Installation lead pressure promptly exposed the lack of uniform tension on end turns. Expansion force causes the strain disparity to become evident in pulsing. There is no inward pressure in a manual or coiler wind (the balance state is a spaced wind). And it's the deviation in the upper (top, right) coil that exposes the strain (compression) deviation. Not the strain itself. But it is the difference in strain that causes the temperature difference. Were the end turn more flush they might look rather perfect in test. In operation under the repeated heat expansion of firing the hotter wind or turns would likely continue an advance to higher thermal output. Happens for all winds but a vicious circle, it accelerates with higher temp's. Given all this it doesn't seem the winds were torched. Neither to actually finalize oxidation.

Now again, in this rising temperature pressure scenario, as amps go up here on the unbalanced wind what happens to overall output as the internal atty pressure rises? Do we get more production? Or, less? What happens to vaporization? Does it continue apace? Or does it diminish in proportion to the rising vapor pressure and resistance it presents to inflow?

Ideas and thoughts.

Good luck all.

What stifles the vape?

Little thought experiment for you and your remarks should be interesting on this. What happens to airflow when temperature drives pressure up rapidly in our atomizers? When vapor pressure rises, does vaporization increase? Or does it get stifled? The definition is important here. Think of internal pressure as resistance. Does drawing harder then get more output? Or is it diminishing return?

And it doesn't much tell when we first fire it always. May vape great…for a while. Even a hot leg will give you great heat output, at first. Until the effect of the excess heat starts to impact surrounding connections (wire and posts) as well as juice and wick. We often get what was pretty in the video; until, we don't.

Now movin' on...

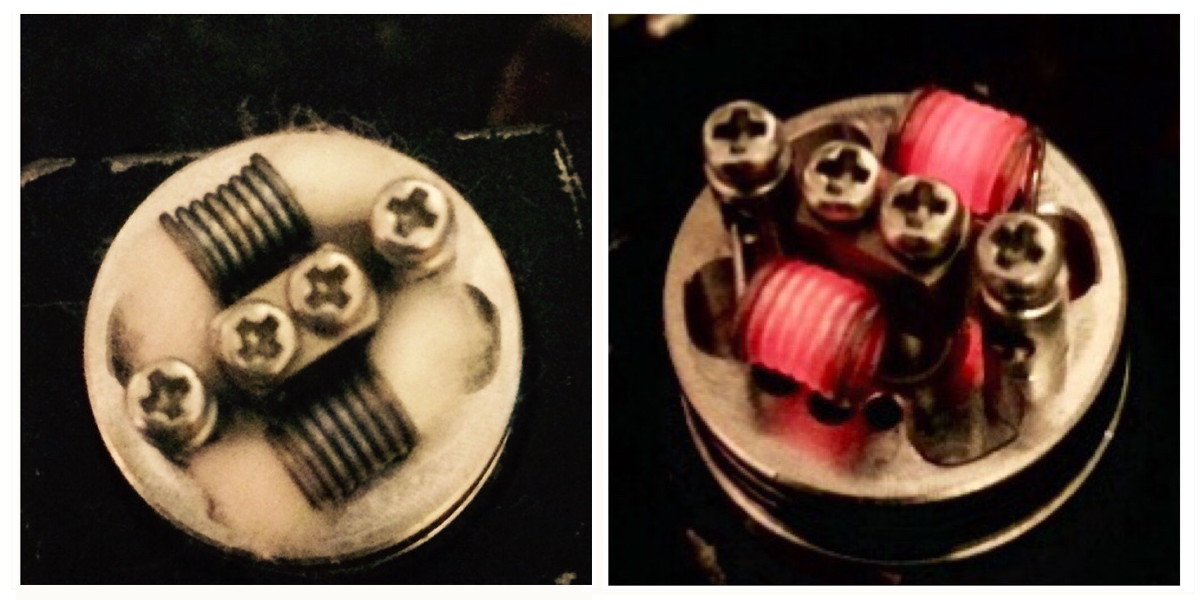

Lifted this image from imgur to illustrate what happens without strain. First the obvious, significant thermal output diff between the pair (at app low V). To the recently initiated this might be well, great even firing coil. When power is upped (longer pulse) what do you think will happen to the top one?

Let me share what I see and can surmise from the above.

Coils were wound by the same method. Likely, a tight hand wind. Poss, but less likely a coiler as suggested by the one symmetrical wind. It is very difficult to maintain diametrical concentricity with a hand wind without tension winding. When we hand tension it's common to see diff levels of strain applied for a wound pair. That we see here with the stepped coil (top, left). With hand wind or coiler they will both expand in diameter and separate laterally. We can't correct from the deviation from the wind diameter spec; but, it seems an attempt was made to correct for contact in part for the cooler coil (top, right) based on the slightly darker color (bottom, left). Yes, it was compressed. So was the other resulting in the stepping due to diameter eccentricity and over-tightening. So the user likely chose not to continue the effort with the coil (bottom, right) continuing to get hotter. Which meant having to leave the coils in a state of temperature imbalance.

Installation lead pressure promptly exposed the lack of uniform tension on end turns. Expansion force causes the strain disparity to become evident in pulsing. There is no inward pressure in a manual or coiler wind (the balance state is a spaced wind). And it's the deviation in the upper (top, right) coil that exposes the strain (compression) deviation. Not the strain itself. But it is the difference in strain that causes the temperature difference. Were the end turn more flush they might look rather perfect in test. In operation under the repeated heat expansion of firing the hotter wind or turns would likely continue an advance to higher thermal output. Happens for all winds but a vicious circle, it accelerates with higher temp's. Given all this it doesn't seem the winds were torched. Neither to actually finalize oxidation.

Now again, in this rising temperature pressure scenario, as amps go up here on the unbalanced wind what happens to overall output as the internal atty pressure rises? Do we get more production? Or, less? What happens to vaporization? Does it continue apace? Or does it diminish in proportion to the rising vapor pressure and resistance it presents to inflow?

Ideas and thoughts.

Good luck all.

Last edited:

I was just reading this thread, and watched the video at the mark the OP referenced, concerning heating our coils to a glow for cleaning, and preparing. Might be worth listening to, and thinking about.

The end of microcoils? | E-Cigarette Forum

The end of microcoils? | E-Cigarette Forum

I was just reading this thread, and watched the video at the mark the OP referenced, concerning heating our coils to a glow for cleaning, and preparing. Might be worth listening to, and thinking about.

The end of microcoils? | E-Cigarette Forum

Here's my advice. Don't try to build contact coils with a coiler. It will leave gaps that may result in unpredictable over-heating. A close contact non-insulated touching vaporizer coil is a short. This is inhibited by proper oxidation which Kanthal should be for our application. You can get there easily by tension winding.

I agree with Dr. Farsalinos that heating wire can compromise it. I would strongly disagree that the word destroy is at all appropriate or scientific. External or internal heating (annealing, pulsed) can change a wire's internal molecular structure, strain as well for the better. And both are and often should be used to increase performance and stability. Rapidly and or irregularly overheating wire can compromise its surface introducing imbalances which can produce things like cracks or material loss in use. It may result in some off-gassing. And that is what we don't want...in operation. But this is far less of a problem with optimally oxidized Kanthal.

The subtle argument from authority here on coilers is not persuasive. Coilers don't make predictable results. The create winds with the appearance of functionality. For many the winds they create spread laterally and diametrically lacking the needed rigidity for form or proper contact oxidation. They can only be made into usable spaced or contact winds with further considerable energy inputand/or handling. The latter of itself can introduce considerable strain disparity. Uniformity of strain enhances wire performance, vaporization and stability of vape temperature.

Why do this when you have a straightforward way of going directly to the intended most predictable electrical result? What Dr. Farsalinos seems to suggest we should have. I think it's unfortunate that Dr. Farsalinos' nods to the notion of a coiler being adequate for vaporizer winds while on the other hand alluding to the long term risks to lung function. This is ironic and unfortunate ignoring a coilers actual utility. A serious misstep on his part which challenges his otherwise credible and important arguments.

There are two types of properly prepared vaporizer coils. A symmetrical and balanced (strain) open (or spaced) coil and a symmetrical contact coil (Kanthal) properly oxidized. Departures may exhibit erratic behavior. Otherwise, why do we need temperature control? Aren't such devices intended to be used with eccentric spaced winds? A million ways we can wind and we experiment with many. I'm talking about accurate, predictable and stable electrical performance in practical (achievable) terms.

Thanks for your post. Very interesting indeed. I mostly agree with Dr. Farsalinos. Overheating is unnecessary. Do a t.m.c. and use as specified. Overheating problem solved (for most of us). That's how we convince the master planners we're in charge of our own vape. We can duplicate it easily.

A million of us.

Good luck.

Last edited:

Do a t.m.c. and use as specified.

But what if your TMC is not perfect? And how would you know without pulsing it a couple of times? I need to see that it glows from inside out, don't I?

I'm so confused--again...

O.K. After reading over 40 interesting and entertaining pages of this thread yesterday, I decided that I would give this a try. I also wanted to solve the problem of adjusting one leg of the coil to reach a post without damaging the coil. I think I succeeded in this.

I grew up in a steel fabrication shop and prefer to build everything by hand. Sadly, I will have to buy a fly reel or bait casting reel, because I can't create one of those in my apartment. I grabbed a 1/8" welding rod in the shop and took the flux off of it. That was to be my Mandrel. So far, I only have the Mandrel built, but that was the complicated part. I will have to build the rest this weekend. That shouldn't be a problem. The Mandrel is completed however and I did a test coil on it while holding it in my hand with a weight hanging from the end of the 24g Kanthal. I was not able to take a photo of that, due to both hands being full. The mandrel is 1/8" and is very close to 3.0mm which is what I like to build and wick on my Aeolus.

I grabbed a 1/8" welding rod in the shop and took the flux off of it. That was to be my Mandrel. So far, I only have the Mandrel built, but that was the complicated part. I will have to build the rest this weekend. That shouldn't be a problem. The Mandrel is completed however and I did a test coil on it while holding it in my hand with a weight hanging from the end of the 24g Kanthal. I was not able to take a photo of that, due to both hands being full. The mandrel is 1/8" and is very close to 3.0mm which is what I like to build and wick on my Aeolus.

Here are some photos that I took. Please excuse the photos. They were taken with my cell phone, in my shaky old hands, under some horrible lighting in my kitchen. That towel is supposed to be crimson red. I do miss my Nikon D700 and all of my fast glass. I also hope all of the photos show up here in one attempt.

I had no target here. I just grabbed the leg with needle nose pliers and bent it with my finger to have something to photograph. ;-)

I didn't want to go overboard with photos, but I wanted to get enough, that others could see exactly what was done. I did not need the coil and only wrapped it to test the theory of the latitudinal leg that I was thinking about last night while reading Mac's posts.

Once I have the whole thing completed, I promise to take some more photos and post them for you guys.

I hope my first post is not too disappointing.

I grew up in a steel fabrication shop and prefer to build everything by hand. Sadly, I will have to buy a fly reel or bait casting reel, because I can't create one of those in my apartment.

I grabbed a 1/8" welding rod in the shop and took the flux off of it. That was to be my Mandrel. So far, I only have the Mandrel built, but that was the complicated part. I will have to build the rest this weekend. That shouldn't be a problem. The Mandrel is completed however and I did a test coil on it while holding it in my hand with a weight hanging from the end of the 24g Kanthal. I was not able to take a photo of that, due to both hands being full. The mandrel is 1/8" and is very close to 3.0mm which is what I like to build and wick on my Aeolus.

I grabbed a 1/8" welding rod in the shop and took the flux off of it. That was to be my Mandrel. So far, I only have the Mandrel built, but that was the complicated part. I will have to build the rest this weekend. That shouldn't be a problem. The Mandrel is completed however and I did a test coil on it while holding it in my hand with a weight hanging from the end of the 24g Kanthal. I was not able to take a photo of that, due to both hands being full. The mandrel is 1/8" and is very close to 3.0mm which is what I like to build and wick on my Aeolus.Here are some photos that I took. Please excuse the photos. They were taken with my cell phone, in my shaky old hands, under some horrible lighting in my kitchen. That towel is supposed to be crimson red. I do miss my Nikon D700 and all of my fast glass. I also hope all of the photos show up here in one attempt.

I had no target here. I just grabbed the leg with needle nose pliers and bent it with my finger to have something to photograph. ;-)

I didn't want to go overboard with photos, but I wanted to get enough, that others could see exactly what was done. I did not need the coil and only wrapped it to test the theory of the latitudinal leg that I was thinking about last night while reading Mac's posts.

Once I have the whole thing completed, I promise to take some more photos and post them for you guys.

I hope my first post is not too disappointing.

Nice job Wilson, will look forward to seeing more.

O.K. After reading over 40 interesting and entertaining pages of this thread yesterday, I decided that I would give this a try. I also wanted to solve the problem of adjusting one leg of the coil to reach a post without damaging the coil. I think I succeeded in this.

I grew up in a steel fabrication shop and prefer to build everything by hand. Sadly, I will have to buy a fly reel or bait casting reel, because I can't create one of those in my apartment.I grabbed a 1/8" welding rod in the shop and took the flux off of it. That was to be my Mandrel. So far, I only have the Mandrel built, but that was the complicated part. I will have to build the rest this weekend. That shouldn't be a problem. The Mandrel is completed however and I did a test coil on it while holding it in my hand with a weight hanging from the end of the 24g Kanthal. I was not able to take a photo of that, due to both hands being full. The mandrel is 1/8" and is very close to 3.0mm which is what I like to build and wick on my Aeolus.

Here are some photos that I took. Please excuse the photos. They were taken with my cell phone, in my shaky old hands, under some horrible lighting in my kitchen. That towel is supposed to be crimson red. I do miss my Nikon D700 and all of my fast glass. I also hope all of the photos show up here in one attempt.

I had no target here. I just grabbed the leg with needle nose pliers and bent it with my finger to have something to photograph. ;-)

I didn't want to go overboard with photos, but I wanted to get enough, that others could see exactly what was done. I did not need the coil and only wrapped it to test the theory of the latitudinal leg that I was thinking about last night while reading Mac's posts.

Once I have the whole thing completed, I promise to take some more photos and post them for you guys.

I hope my first post is not too disappointing.

Nice effort. Good pics. Good tight coil. Only word of caution as I shared back in Spring '13 when I dropped this idea on ECF…too loose, you don't hit adhesion (closest proximity); and too tight and you'll thin wire excessively raising it's res value. Somewhere in the middle is the sweet spot that balances the internal strain to induce an optimal for electron flow. You'll get to adhesion easily enough and start enjoying the benefits. With mechanical and weight winding you'll need to watch for over-tightening. The key indicator is your leads will tend to go hot often even at very low voltage. The more the excess strain the greater the likelihood.

Once you learn the weight, mechanics, etc. for the wire gauge you'll own it and be able to duplicate it as easily as your medium-rare on the BBQ.

Good luck W.

I agree Mac. Frankly, I don't think we need nearly as much weight as I was seeing earlier in the thread. I don't feel the need to bring the wire to stretching. Just some consistent tension of a few pounds, because all of the real magic is going to happen inside the wire at the point where it rolls around the mandrel.Nice effort. Good pics. Good tight coil. Only word of caution as I shared back in Spring '13 when I dropped this idea on ECF…too loose, you don't hit adhesion (closest proximity); and too tight and you'll thin wire excessively raising it's res value. Somewhere in the middle is the sweet spot that balances the internal strain to induce an optimal for electron flow. You'll get to adhesion easily enough and start enjoying the benefits. With mechanical and weight winding you'll need to watch for over-tightening. The key indicator is your leads will tend to go hot often even at very low voltage. The more the excess strain the greater the likelihood.

Once you learn the weight, mechanics, etc. for the wire gauge you'll own it and be able to duplicate it as easily as your medium-rare on the BBQ.

Good luck W.

I agree Mac. Frankly, I don't think we need nearly as much weight as I was seeing earlier in the thread. I don't feel the need to bring the wire to stretching. Just some consistent tension of a few pounds, because all of the real magic is going to happen inside the wire at the point where it rolls around the mandrel.

Bingo! You understand the mechanics.

Good luck.

THere are some photos that I took. Please excuse the photos. They were taken with my cell phone, in my shaky old hands, under some horrible lighting in my kitchen. That towel is supposed to be crimson red. I do miss my Nikon D700 and all of my fast glass. I also hope all of the photos show up here in one attempt.

The photos came out great in my opinion!

Nice to see another Nikon kindred spirit. After 30+ years (my F3HP days) I still love my 105/1.8 lens, even though I have to use it in manual. I like the zooms I have but there is nothing like a fast, sharp prime lens!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 733

- Replies

- 9

- Views

- 1K

- Replies

- 102

- Views

- 10K

- Locked

- Replies

- 33

- Views

- 13K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)