I've been doing a lot of practice,trying to wind a coil so no light passes between coils.Harder said than done.

I watched a video showing oxidatizing a coil and I've been pulsing mine way too fast.Now that I've seen oxidizing done that will help.

Has anyone found certain brands of 18650 to perform better than others?

I'm using Lg H2 2500 and they seem to work okay but I go through 4 cells a day.

Theres now a li-mn cell but I'm not up on 18650 yet.

Only four there Rob?

Don't' give up. I have my days winding nothing but pretty decoration winds. Don't toss 'em. You can form them down to a slightly small screw Ø spaced wind. I use 'em for comparison vapes and the occasional juice/atty combo that only runs well that way (mostly some tab's).

For the benefit of the gallery, some refresher notes.

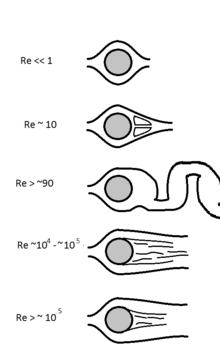

The initial intro of the micro brought about the close contact coil. Subsequently torching the coils with external compression during or after were introduced to aid in forming tighter coils. I favored the former (during the burn) on the Protank thread as this seemed to expedite tight contact with less energy and erosion of the wire surface. However, both techniques still produced very warm output. They also got hotter in operation than standard coils as they were essentially thermally shorting across each other. Torching if anything hampered significant alumina development.

Any coil can be oxidized if properly powered. To initiate alumina development that serves to isolate electrical flow required I found that the turns must be in

adhesion, as I describe, a generic term for closest proximity. The more uniform that wind and contact the more effectively and quickly that it is formed.

Rob, if you're seeing more than minute incidental gaps there is simply not enough tension to induce strain (elongation). Tensioning off the perpendicular (and away from the wind) will actually reduce the lateral strain being applied. The wind may actually pull apart if the longitudinal strain is greater than the lateral. That would not be a tensioned microcoil.

The downside of the jig for new users is that simply adding some pull will allow the rotation effort to simply

form or bend the wire. Subsequent turns will impart a longitudinal sideways force pushing turns together. This is not elongation. The turns in operation will strive to return to the form or original shape wound (bent) with repeated thermal expansion. Such tend to separate leaving what is often an inadequately insulated close or intermittent contact short. With power and expansion it becomes more evident. To put it bluntly, for some disposed to that kind of cynicism, it's proof positive microcoils suck. But no, just the wind did.

Learning the necessary mechanics is an individual achievement. We each have to arrive at the right balance of eye, hand and mental coordination. A bit dicier with a jig as it's quite easy to miss when we've introduced competing

forming forces.

So can't emphasize enough that winding directly off the spool is the best way to observe and consistently achieve adhesion. With the bit right on the edge of the spool serving as both a pivot and leverage point for the angle or degree of attack to the wind. Good thumb pressure on the screwdriver or pin vise with firm resistance or slight opposing pull on the spool itself with the other hand is usually enough.

There should be no visible gaps.

If you're having diff finding the adhesion point (and slightly beyond), drop down a gauge or two until you've achieved the body mechanics to comfortably execute a smooth flow of rotation under tension.

Now don't any of you take this personal. We all have our days when we've got sh!!t for hands. Some of us more than others. This too shall pass.

Good luck.