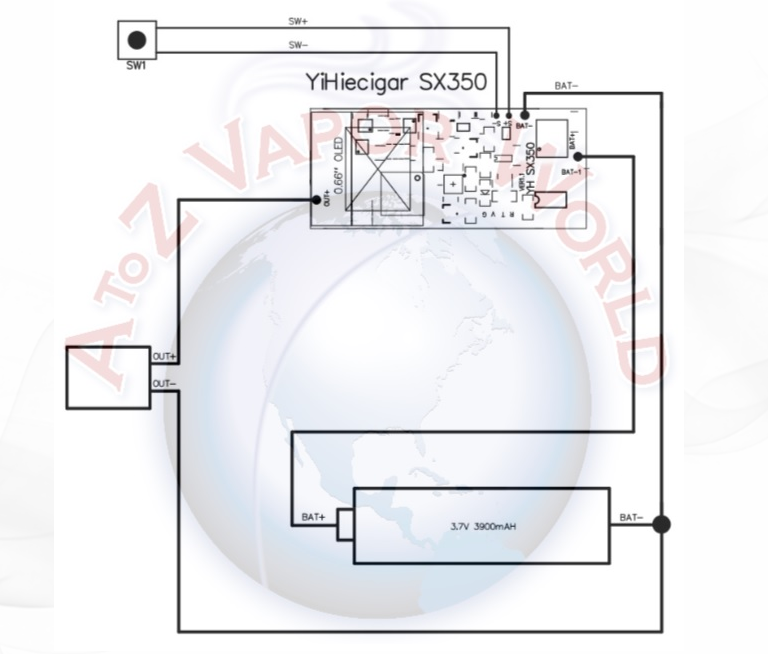

Okay so I know some basic knowledge of circuits and soldering. But please help me out on this, I have no idea what wires go where.

Can someone please help me out to clarify which wire is which and where it goes? I'm a noob in this area apparently and I can find any tutorials for this anywhere..

Can someone please help me out to clarify which wire is which and where it goes? I'm a noob in this area apparently and I can find any tutorials for this anywhere..

I need help with materials I need, I need to make sure I have it all.

Can you guys help me out and put a basic list of everything I'll need to do this... And possibly where to buy it if you were in my shoes. Would pre wired 510 connectors and pre wired battery holders be the way to go?

Alright, thanks.

Can someone please help me out to clarify which wire is which and where it goes? I'm a noob in this area apparently and I can find any tutorials for this anywhere..

Can someone please help me out to clarify which wire is which and where it goes? I'm a noob in this area apparently and I can find any tutorials for this anywhere..I need help with materials I need, I need to make sure I have it all.

Can you guys help me out and put a basic list of everything I'll need to do this... And possibly where to buy it if you were in my shoes. Would pre wired 510 connectors and pre wired battery holders be the way to go?

Alright, thanks.