Whether it’s your first time buying a charger or you’re replacing an old one, it’s worth knowing what extra features are worth paying for, including the charger quality.

As a professional battery charger manufacturer, xtar exposed its charger product testing process for the first time. Let’s see how we test our battery chargers.

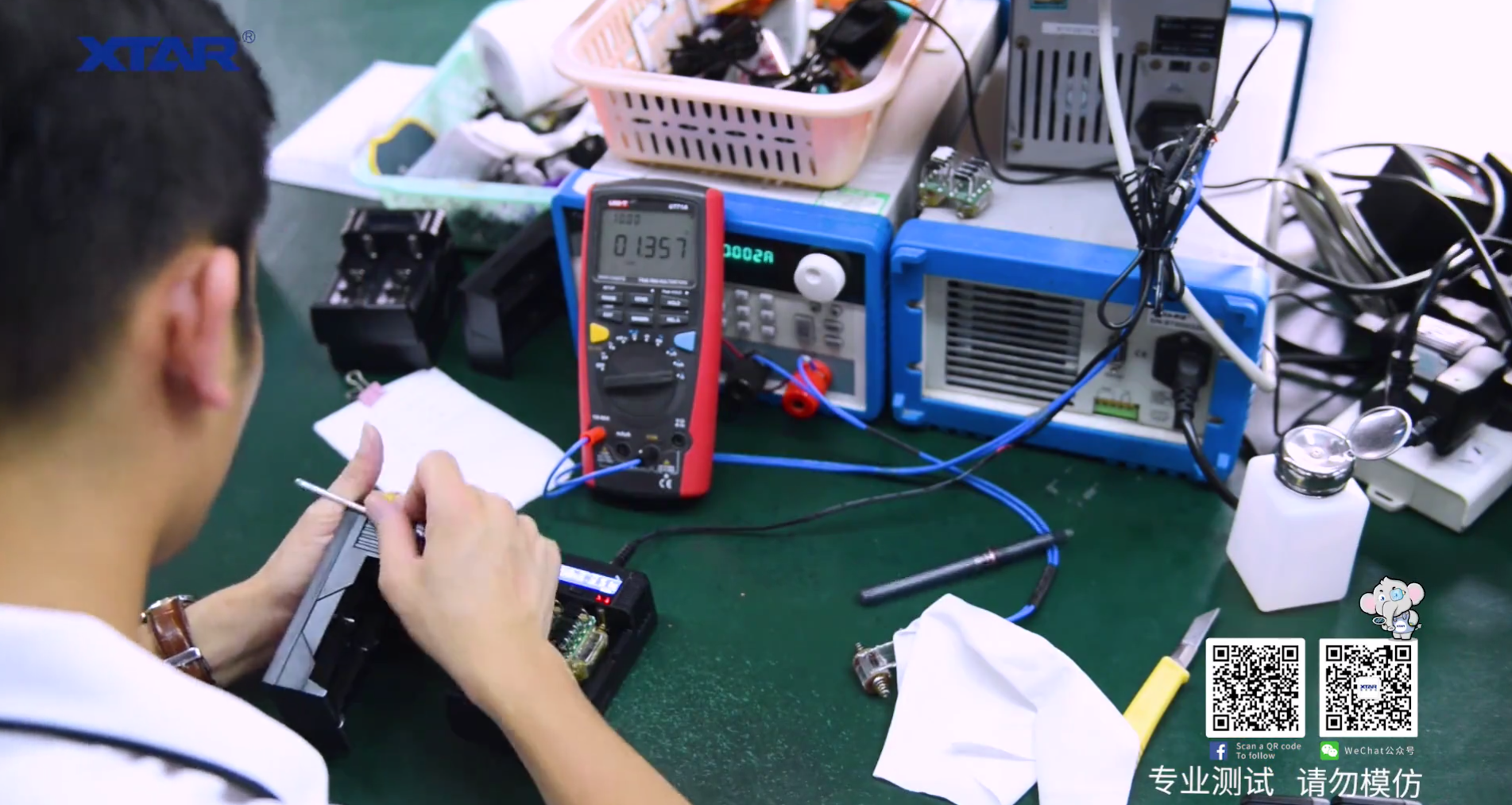

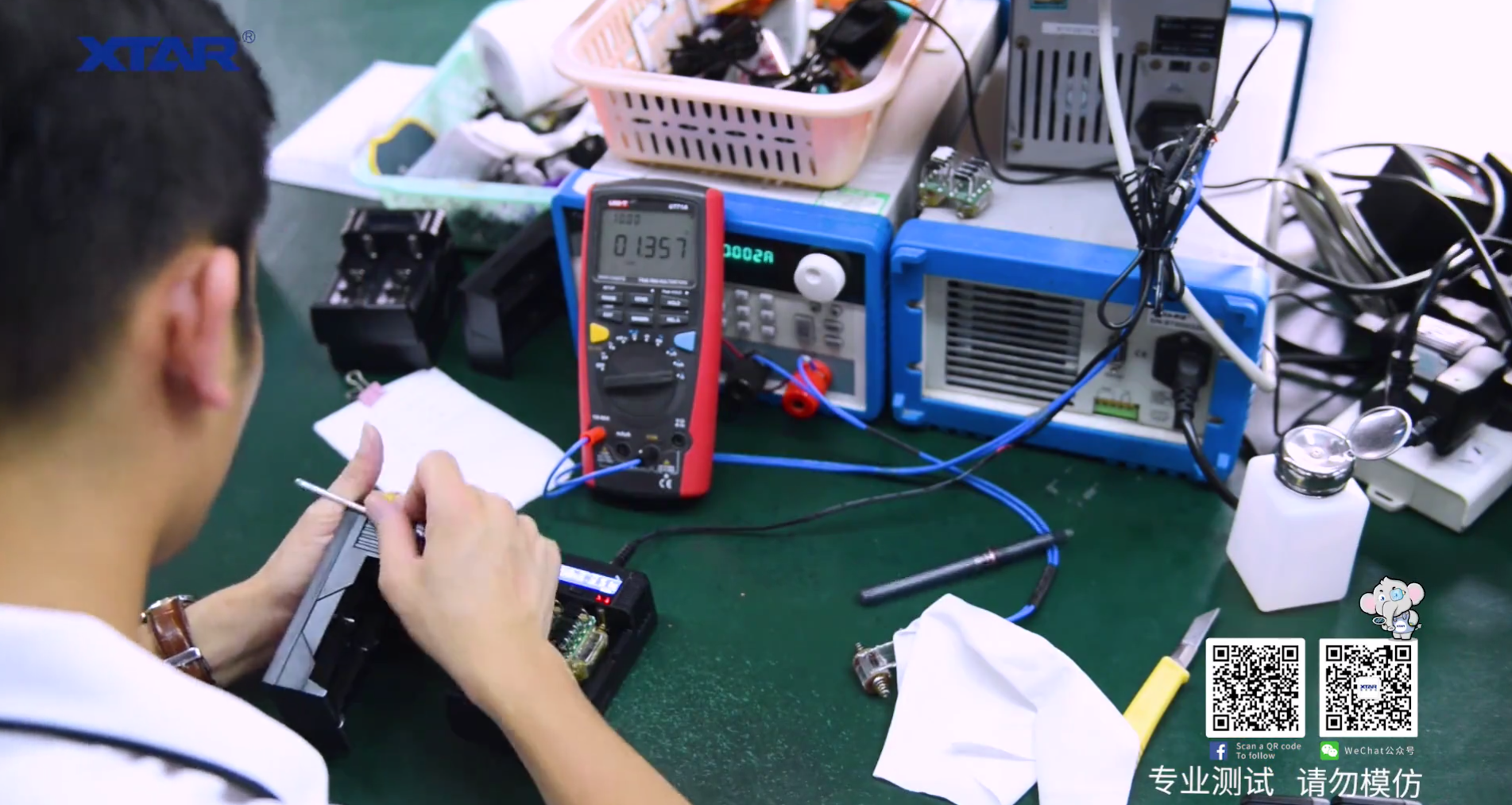

1. Over ten tests for chargers’ appearance

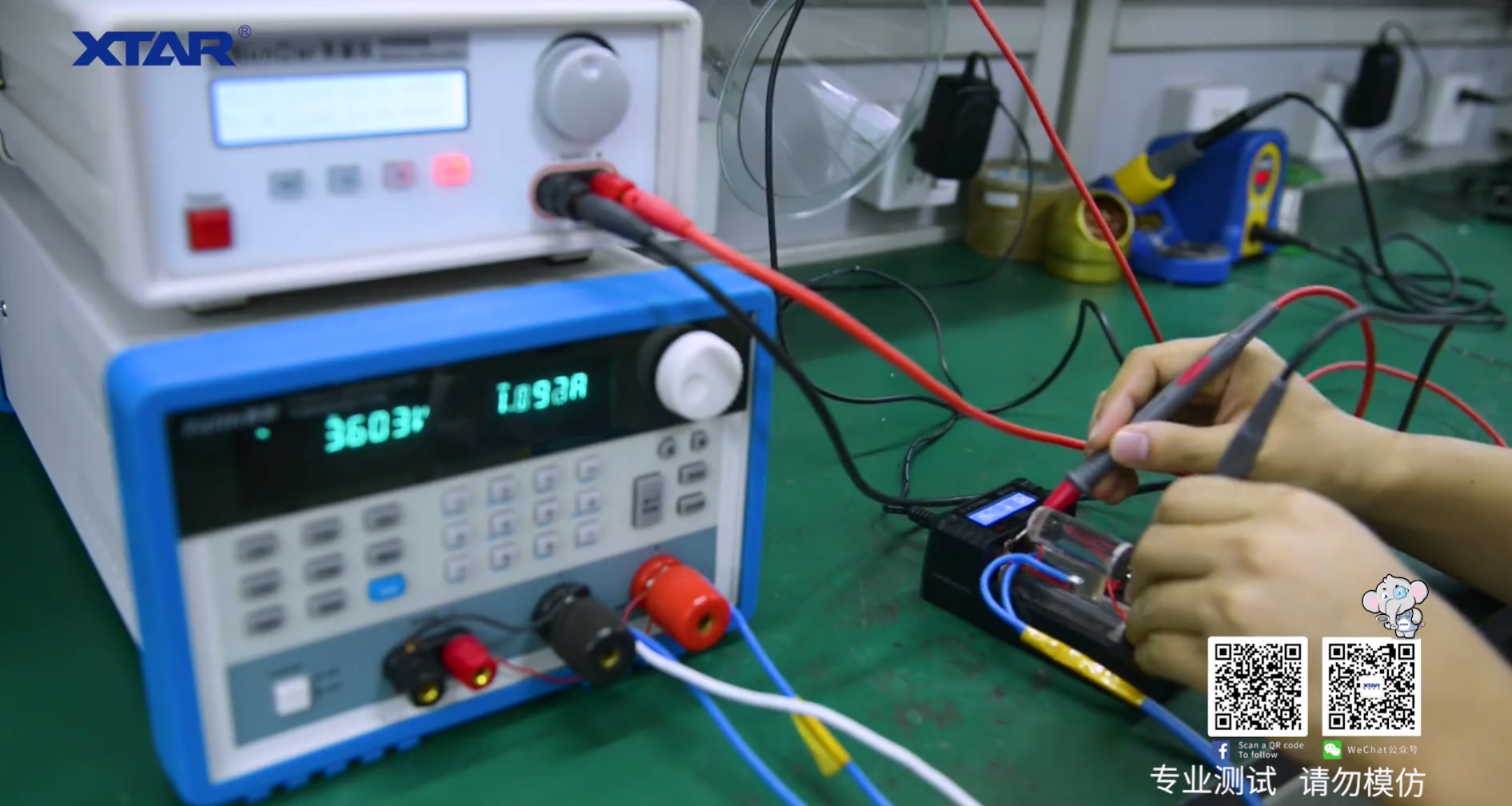

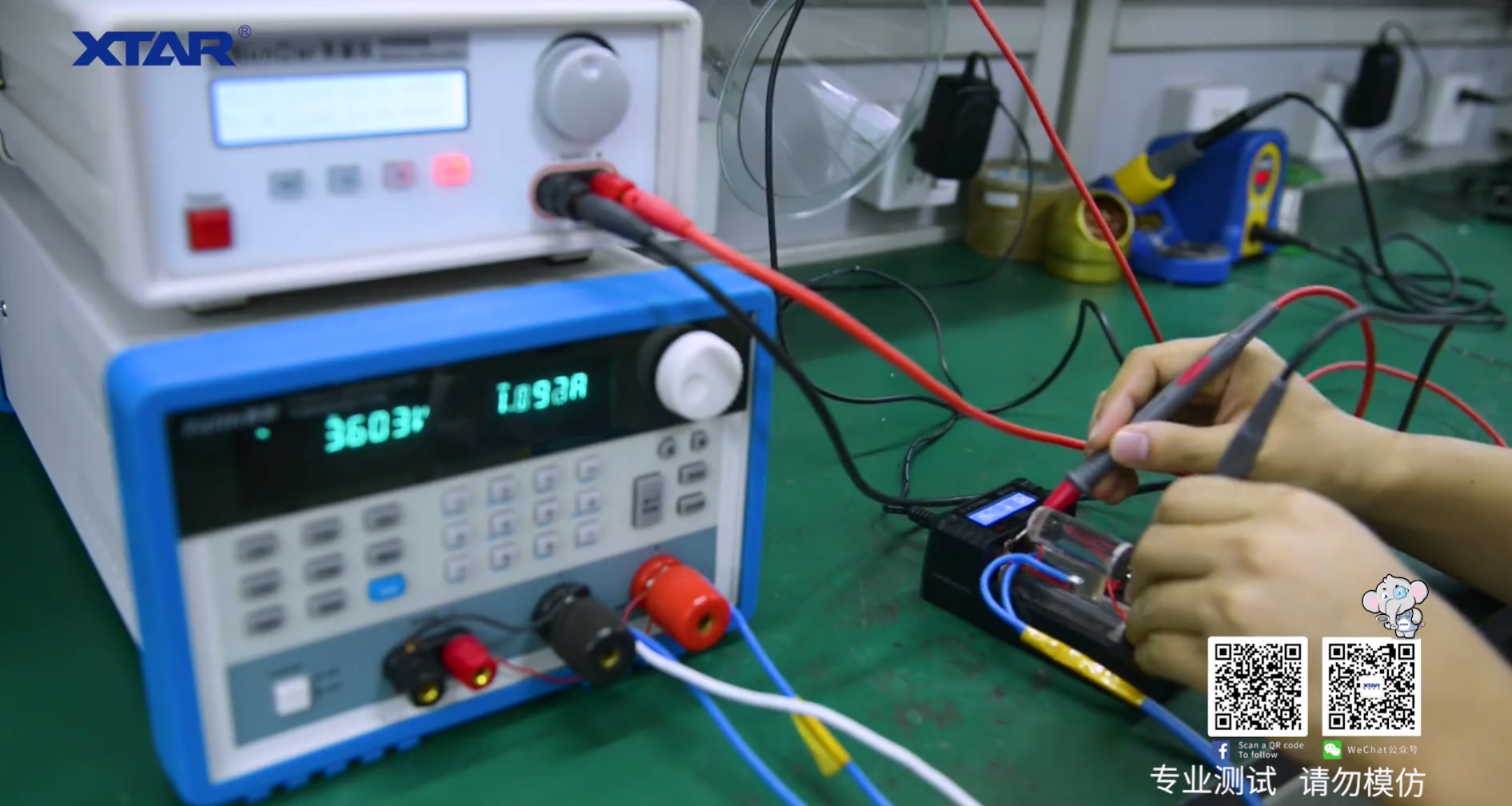

2. Accurate testing for judging battery voltage after fully charged with professional equipment, keeping the performance parameter deviation within 1%.

3. Aging test. Simulating the daily use of battery chargers, testing the stability of electronic components. Test duration: 1-10 hours.

4. Extreme high temperature test to ensure the chargers use safety in extreme environments. Test duration: 1-5 hours. Test temperature: -20℃-65℃.

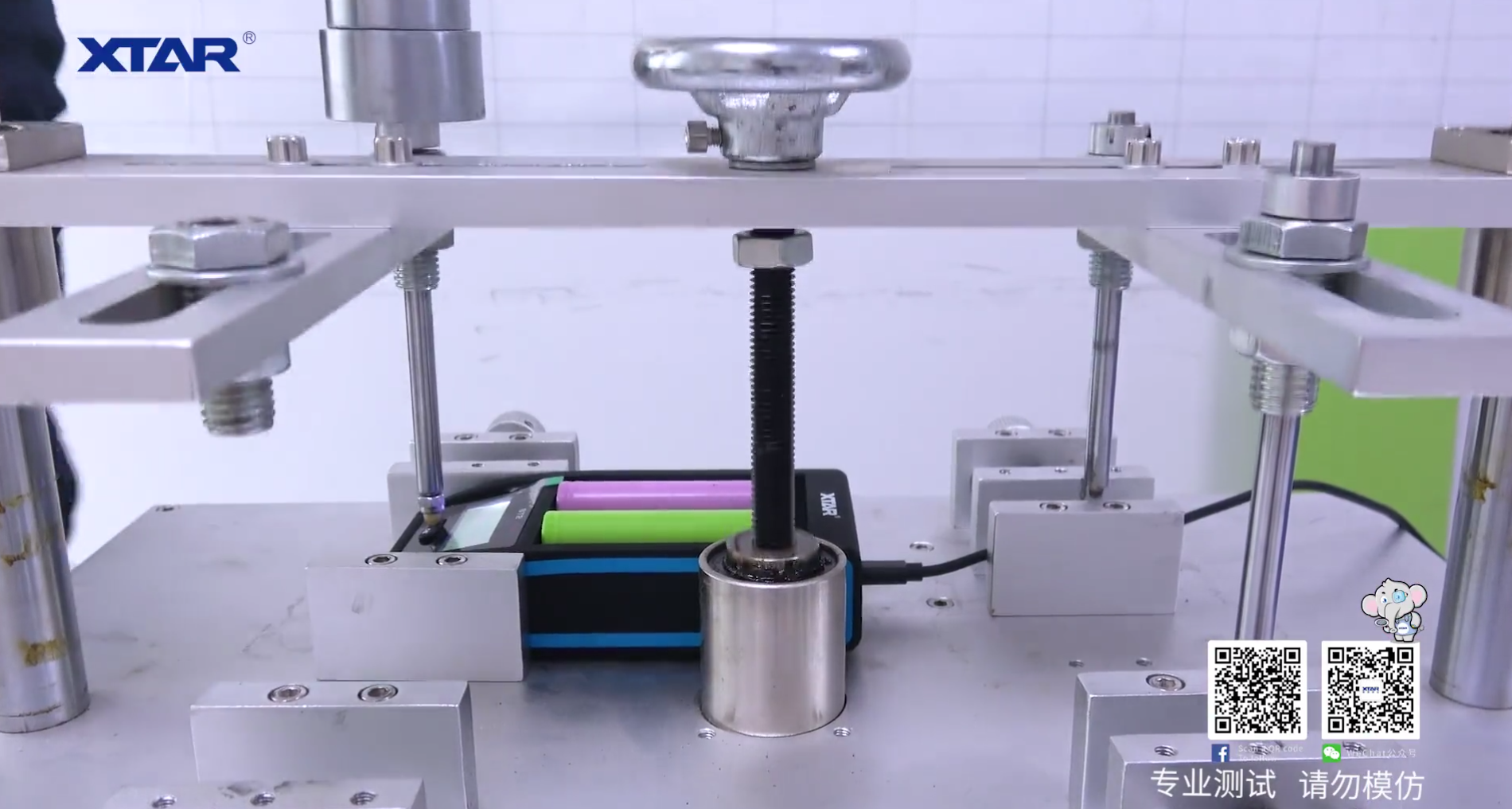

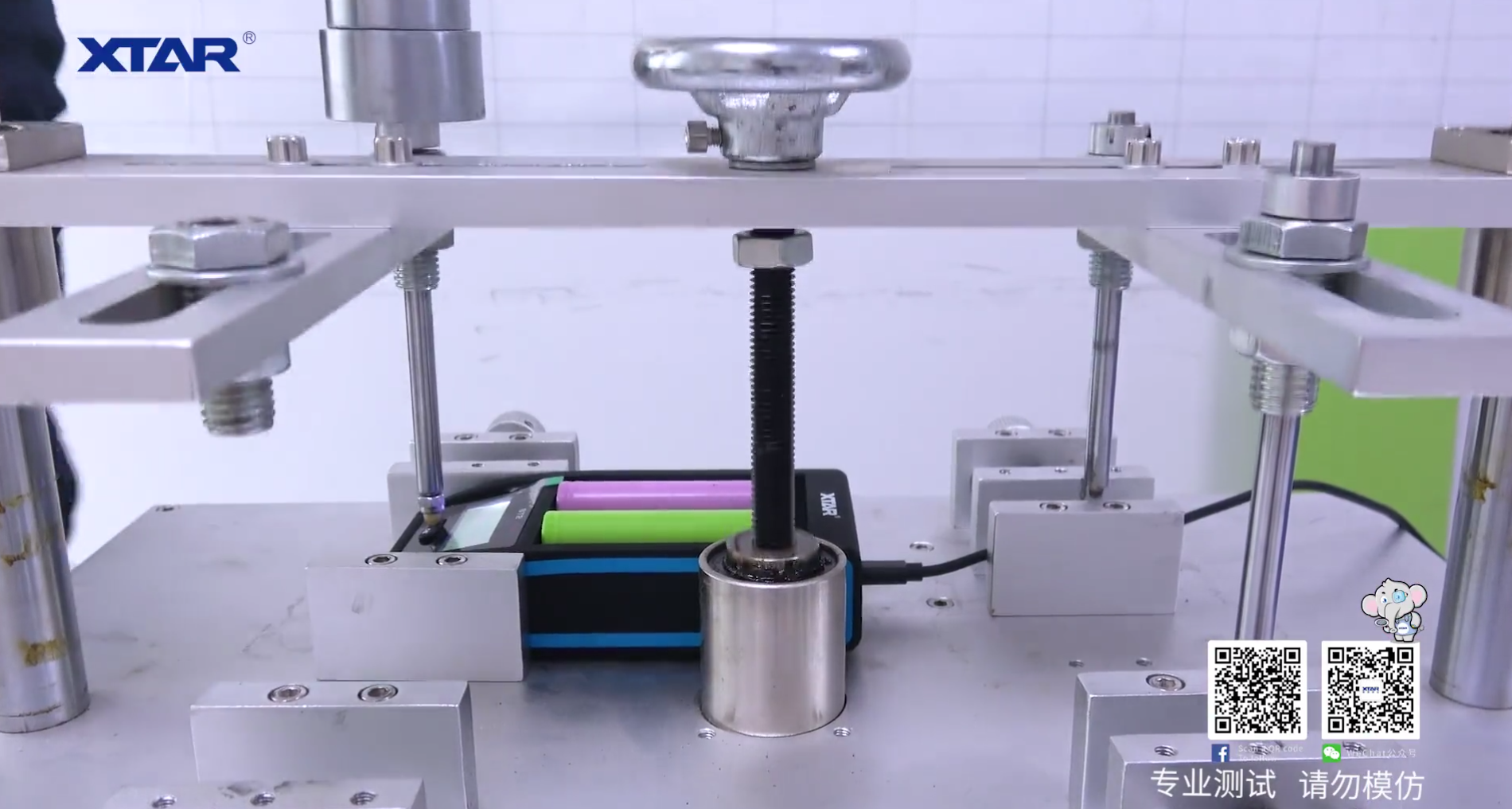

5. Button press test. Check the service life of the buttons on the chargers and eliminate the bad buttons of the products. Test duration: 1-5 hours, test times: 2000-50,000 times.

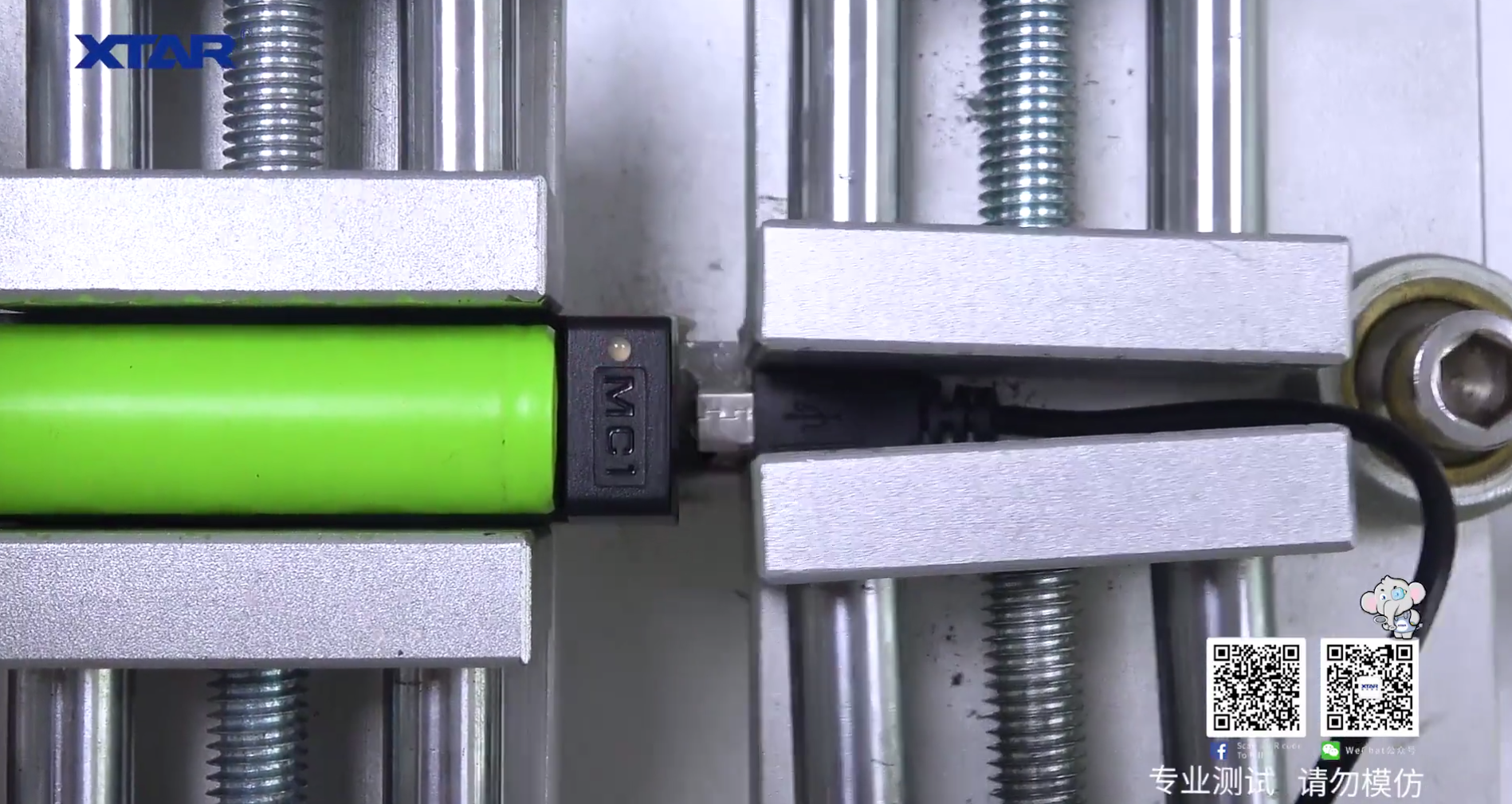

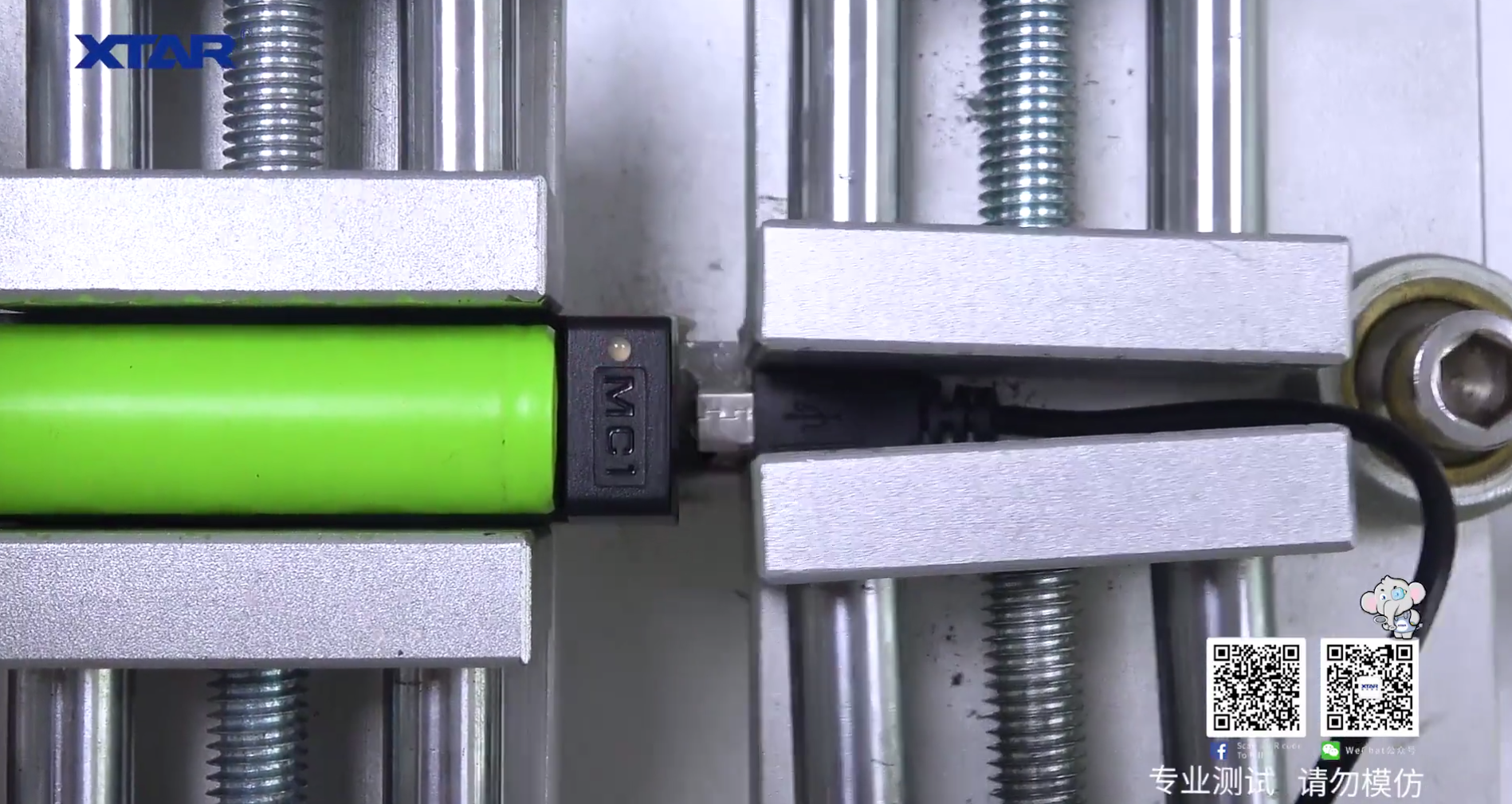

6. Interface plug detection. Test duration: 1-5 hours, test times: 2000-50000 times.

7. Anti-drop test. Simulate the battery charger's daily use environment and test the durability of the housing.

The product quality inspection in xtar is full inspection.

What’s your oldest xtar charger? Share with us below.

As a professional battery charger manufacturer, xtar exposed its charger product testing process for the first time. Let’s see how we test our battery chargers.

1. Over ten tests for chargers’ appearance

2. Accurate testing for judging battery voltage after fully charged with professional equipment, keeping the performance parameter deviation within 1%.

3. Aging test. Simulating the daily use of battery chargers, testing the stability of electronic components. Test duration: 1-10 hours.

4. Extreme high temperature test to ensure the chargers use safety in extreme environments. Test duration: 1-5 hours. Test temperature: -20℃-65℃.

5. Button press test. Check the service life of the buttons on the chargers and eliminate the bad buttons of the products. Test duration: 1-5 hours, test times: 2000-50,000 times.

6. Interface plug detection. Test duration: 1-5 hours, test times: 2000-50000 times.

7. Anti-drop test. Simulate the battery charger's daily use environment and test the durability of the housing.

The product quality inspection in xtar is full inspection.

What’s your oldest xtar charger? Share with us below.