I use blended solvents when extracting flavor from tobacco and vanilla beans, cloves and etc. A recent addition to my extraction methodology, I use a small portion of purified water in all solvent blends to enhance and expedite flavor extraction. Once the extraction and filtering process is complete, the benefits of water cease and as a statistically significant ingredient in an extract it isn't advantageous for "stable" long term storage. Just my personal opinion but for long term storage of extract I want only PG and or VG as a base.

In the past I have used low heat and open air evaporation to remove free water and PGA from extracts prior to storage. This method isn't ideal and isn't able to remove dissolved water (water absorbed at the molecular level), just the free water that exists above the saturation point of the solvents in play. VG is hygroscopic with a relatively high saturation point and readily absorbs water, this dissolved water is - very - difficult to remove.

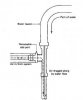

I am familiar with several methods capable of removing dissolved water from oils but only have the equipment and capability of performing one of those methods, vacuum dehydration. Once the extraction and filtering processes are complete I will warm the extract to 160F (71C), and subject it to a high vacuum while being magnetically stirred. Stirring isn't really necessary for such a small quantity but should help. Most of the dissolved water should boil off and exit through the vacuum circuit. In "theory" anyway.....

As an amusing side note, I "inadvertently" boiled the PGA in a blended PGA/PG extract last September while vacuum filtering it. This occurred at room temperature with only a moderate (~20"), vacuum. The PGA boiled vigorously.

In the past I have used low heat and open air evaporation to remove free water and PGA from extracts prior to storage. This method isn't ideal and isn't able to remove dissolved water (water absorbed at the molecular level), just the free water that exists above the saturation point of the solvents in play. VG is hygroscopic with a relatively high saturation point and readily absorbs water, this dissolved water is - very - difficult to remove.

I am familiar with several methods capable of removing dissolved water from oils but only have the equipment and capability of performing one of those methods, vacuum dehydration. Once the extraction and filtering processes are complete I will warm the extract to 160F (71C), and subject it to a high vacuum while being magnetically stirred. Stirring isn't really necessary for such a small quantity but should help. Most of the dissolved water should boil off and exit through the vacuum circuit. In "theory" anyway.....

As an amusing side note, I "inadvertently" boiled the PGA in a blended PGA/PG extract last September while vacuum filtering it. This occurred at room temperature with only a moderate (~20"), vacuum. The PGA boiled vigorously.

I'm looking at this as a possible way to force the solvent into and out of the tobacco giving us the best flavor the tobacco can. Now today is the first day I've even considered this process but If I can get my hands on the equipment I'm willing to give it a try.

I'm looking at this as a possible way to force the solvent into and out of the tobacco giving us the best flavor the tobacco can. Now today is the first day I've even considered this process but If I can get my hands on the equipment I'm willing to give it a try.