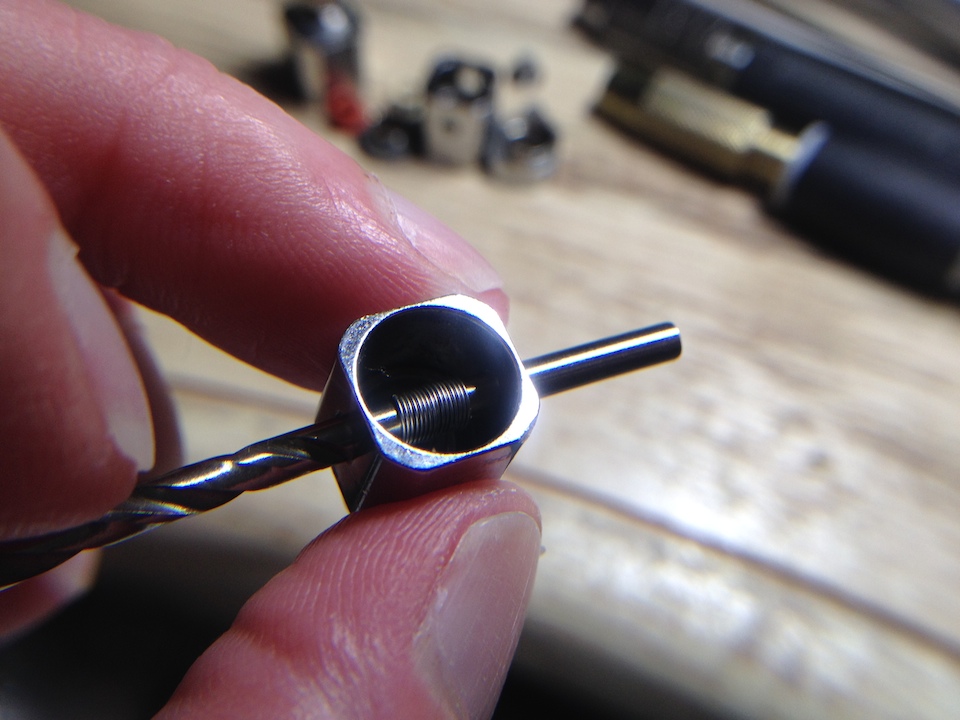

Tensioned coils do squeeze the wick when they heat up and cool down, so they improve the e-liquid flow and Vapour production. But they are so difficult to build!

Really think so Ray?

I find it takes most 30 seconds or less to hand wind a t.m.c. up to 24AWG. A few minutes more to begin prompting oxidation by pulse firing once set (the goal). Merely pulling on the wire will not be enough to make it a spring. Or too much and you make the wind hot (stretch the wire lowering its res). So, I think a lot of peep's just don't know what I'm talking about…because they haven't quite got it. The technique really is simple, roll it…don't pull it or bend it. Done right the wire gets sticky by itself. You've achieved

a balance of strain. Kids do it in a heartbeat making toy jewelry. For me, it's harder than most. Keep in mind, it's about

balanced tension.

Deep oxidation (for higher pwr) is more an art than a skill and requires knowing how this wind responds on a particular device under power. A bit more knowledge of Kanthal as a material, it's metal color temps, is helpful and gained with some experience on simple single-wire winds. Then better higher power handling…

How much a t.m.c. squeezes depends on Ø chosen. The advantage of this wind is uniform contact. Loose but

adequate compression will diffuse (rather than vaporize) a bit more. The sweet spot (tight) for the wicking material usually yields better performance (density). Too tight tho and you'll increase the

speed of flow (like squeezing a water hose). If you can dry out the coil quickly to the point of dry hits as you add power, you're over-wicked for the Ø. Eventually you find a happy place with your media.

Tension (strain) is in every coil we make. Using tension methods to wind has the potential to balance the strain across the entire element. The purpose of this approach is to ensure uniform oxidation. This apparently equalizes minute resistance differentials. It's quite evident in the manner in which the coil heats up as I've referred to in my writings as "the effect". In practical terms the resulting thermal characteristics (uniform end-to-end heating) help ensure more effective vaporization. Years of surveying users as to the diff between a t.m.c. and single-wire open or close-contact winds suggests a greater than 25% greater vapor/density output (the comp here to a comparable close-contact or contact, non-strained coil of similar mass).

The control of strain in rebuilding yields consistency of reproduction, performance and the potential of uniquely precise personalization of the vape. And it just takes 30 seconds to begin. The use of strain management in wind and installation I feel is the most over-looked and undeservedly unappreciated technology in the vaping universe. Vapers I've worked with outside the digital space of ECF, etc. look in marvel at this omission as satisfied users.

Regarding Kanger coils, I still buy square OCC 0.5 Ohm coils, but they are all top-sealed.…

Kanger shoot themselves in the foot when modified the Protank dual-coils to avoid rebuildability. Only a minority of vapers rebuilded the coils, but they all documented it in public... The newer Protank dual-coils tasted orrible, and that was their endgame.

I agree, it's unfortunate they sealed it. It worked better than the RBA and you could put some decent size coils in there. A bit harder for new vapers to achieve alignment and consistent tension but def worth the effort to learn.

Thanks for the nod Ray.

Good luck.