OK, as promised I ran some tests using a thermocouple on a Merlin rta to get some real life temperature measurements inside of a modern atty under real use.

I threaded a .010" thermocouple (click link for source) through the airhole up into the chamber

I tucked just the end up underneath the center coil.

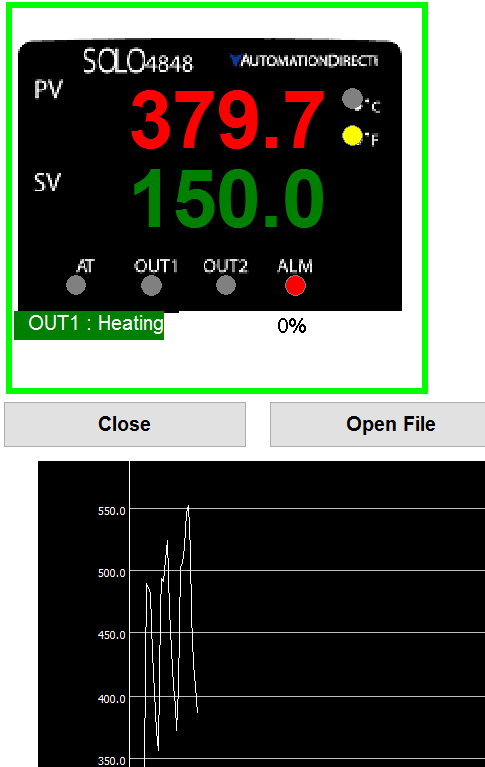

I hooked it up to a Temp Controller that accepts type-k thermocouples. This controller was checked against a Fluke 725 Process Calibrator that is traceable to the NIST, and is within calibration date expiration.

Fluke 725 Process Calibrator used to calibrate/certify the AutomationDiirect Solo Temperature Controller

Calibration data showing NIST traceability:

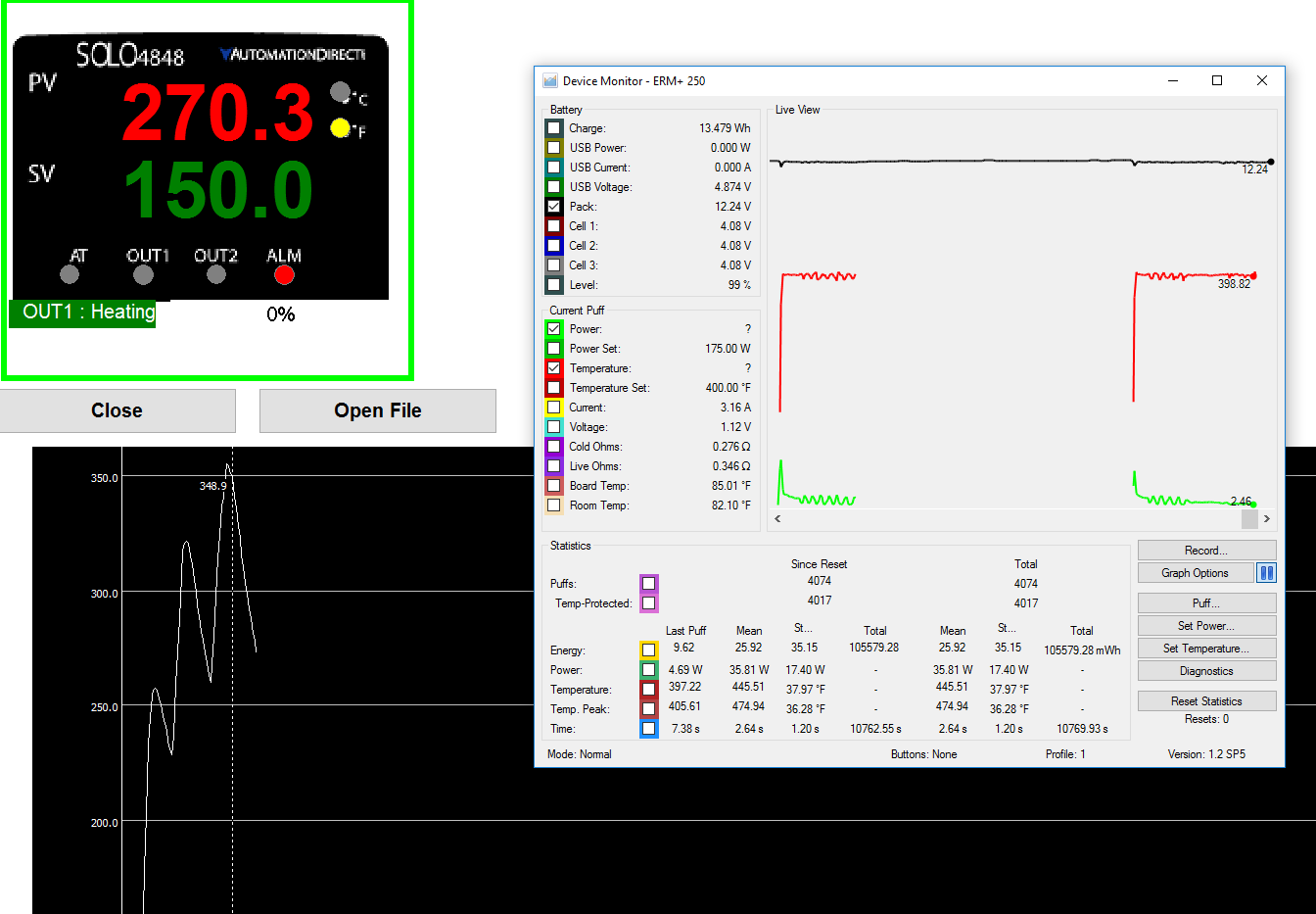

I set the DNA250 to 400F (the insulation of the thermocouple is limited to 500f) and fired the mod while capturing the thermocouple and Evolv's Device Monitor at the same time.

The coil was a 5/6 wrap of 26AWG SS430 around a 3mm drillbit and ohmed out to be 0.317ohms. Used a TCR curve from Steam-Engine, SS430 works well in Watts mode too.

Wick material was rayon, packed firmly inside the coil, and packed lightly inside the juice wells..

I have the airflow and juiceflow wide open for every test unless explicitly stated. I then vaped the tank normally (for me which is a strong MTL style).

The liquid is a 36mg 50/50 mix with no flavor or other additives except nic.

Discovered a couple of things:

WATTS MODE

So, to correlate this for folks running in straight watts mode without TC:

Same 15 watts in watts mode:

Depending on the coil, airflow, chain vape, etc, it doesnt take much wattage to get high temps.

Testing the ends of coil vs center:

Placed sensor under far right coil, it was significantly cooler (about 290) at the same 400 degree setting.

I suspected it would be though, the wick is always more scorched in the middle than on the outside.

Temp in center of the wick

OK, so I stuck the sensor into the middle of the wick, pushed in so the tip of the sensor is inserted to the middle of the coil lengthwise.

So this is the temp the juice sees in the middle of the wick:

Effects of wick saturation

Ok, so all of my tests were done with the juice control wide open to ensure good wick saturation

At 15watts with juice flow wide open:

At 15watts with juice flow closed down (note, not a dry, or even bad tasting hit):

At 20 watts with juice control throttled back:

The 2nd and 3rd hits tasted slightly burnt to me, not dry hits. So I would say that yes, I taste "something" when you get over 500 degrees.

Not going to push the wattage up anymore as the insulation of the sensor cant handle any hotter.

I didnt do a screen capture of it but at 15w the wick center maxed out at about 400 degrees after several chains vapes. The temp was still increasing slightly with each chain hit, but the ROR (rate of rise) with each hit had almost leveled out. I quit after about 6 hits.

So, some conclusions:

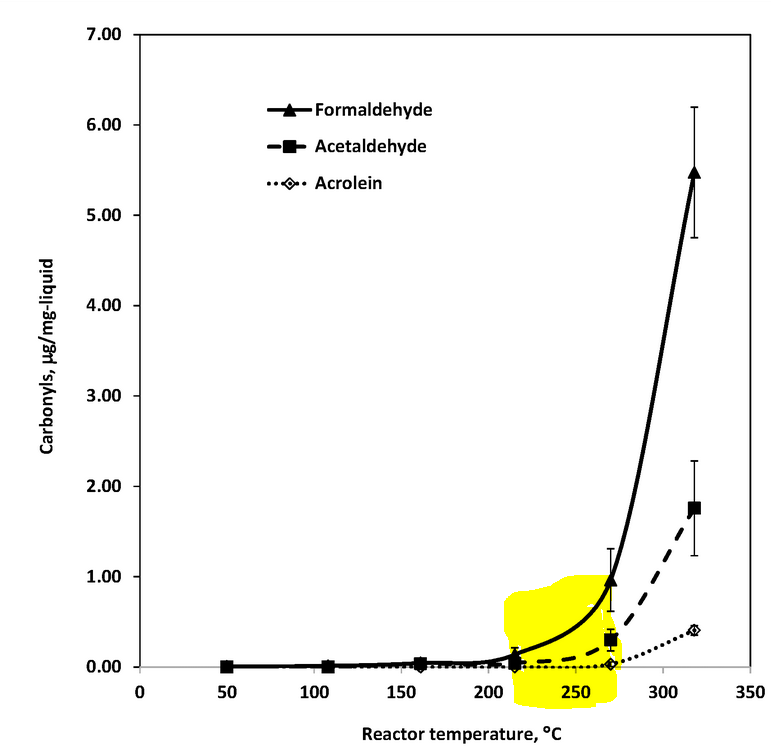

Specifically, I could not "taste" the area highlighted in yellow below.

© Wang

©2017 Mike Petro. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

I threaded a .010" thermocouple (click link for source) through the airhole up into the chamber

I tucked just the end up underneath the center coil.

I hooked it up to a Temp Controller that accepts type-k thermocouples. This controller was checked against a Fluke 725 Process Calibrator that is traceable to the NIST, and is within calibration date expiration.

Fluke 725 Process Calibrator used to calibrate/certify the AutomationDiirect Solo Temperature Controller

Calibration data showing NIST traceability:

I set the DNA250 to 400F (the insulation of the thermocouple is limited to 500f) and fired the mod while capturing the thermocouple and Evolv's Device Monitor at the same time.

The coil was a 5/6 wrap of 26AWG SS430 around a 3mm drillbit and ohmed out to be 0.317ohms. Used a TCR curve from Steam-Engine, SS430 works well in Watts mode too.

Wick material was rayon, packed firmly inside the coil, and packed lightly inside the juice wells..

I have the airflow and juiceflow wide open for every test unless explicitly stated. I then vaped the tank normally (for me which is a strong MTL style).

The liquid is a 36mg 50/50 mix with no flavor or other additives except nic.

Discovered a couple of things:

- The thermocouple data acquisition software limited me in that it only had a sample rate of 1 sec, where Evolv's DM is about 10 times as fast.

- The thermocouple had a lag as compared to Evolv's resistance derived measurements. The lag makes sense though, the coil has to heat up first, then the mass of sensor will heat up.

- Nonetheless, the max temp measured by the thermocouple was about 390. Evolv claims +/- 10 degrees so that was within tolerance, barely.

- I measured off the center coil in this series, about 6-7 tests, the results were very repeatable.

WATTS MODE

So, to correlate this for folks running in straight watts mode without TC:

- SS 430 coil, 26 awg, a 5/6 wrap, 3mm diameter, 0.317 ohms, rayon wick

- In Temp Mode it started out at 20w, and after 1sec dropped to 15 watts to maintain 400 degrees

- First hit was 400 degrees

- Each successive chain vape got a little hotter at the same 15 watts. By the third hit I was getting 440.

Same 15 watts in watts mode:

- 1st hit was airflow control closed off to a minimal MTL setting

- 2nd hit was with airflow opened up (keep in mind that, as shown above, a second hit is normally hotter with all else being equal)

Depending on the coil, airflow, chain vape, etc, it doesnt take much wattage to get high temps.

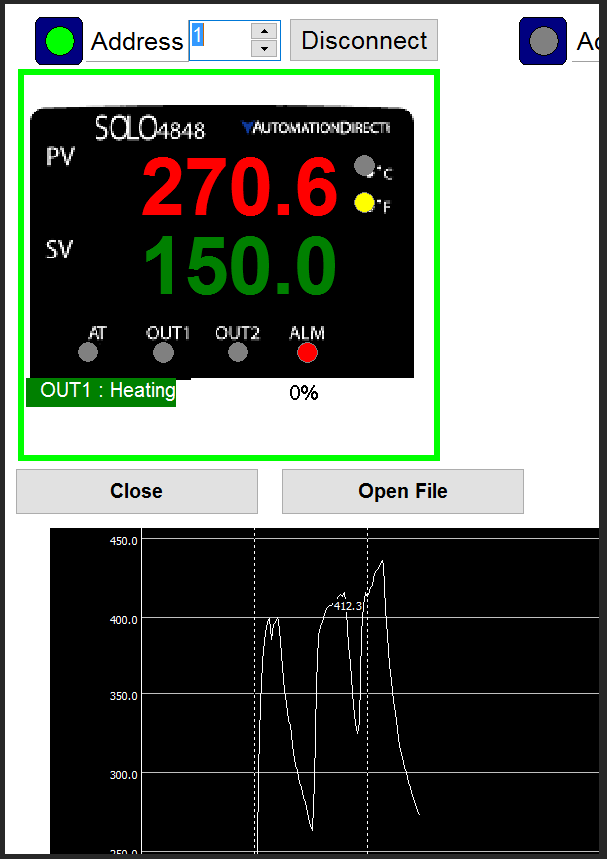

Testing the ends of coil vs center:

Placed sensor under far right coil, it was significantly cooler (about 290) at the same 400 degree setting.

I suspected it would be though, the wick is always more scorched in the middle than on the outside.

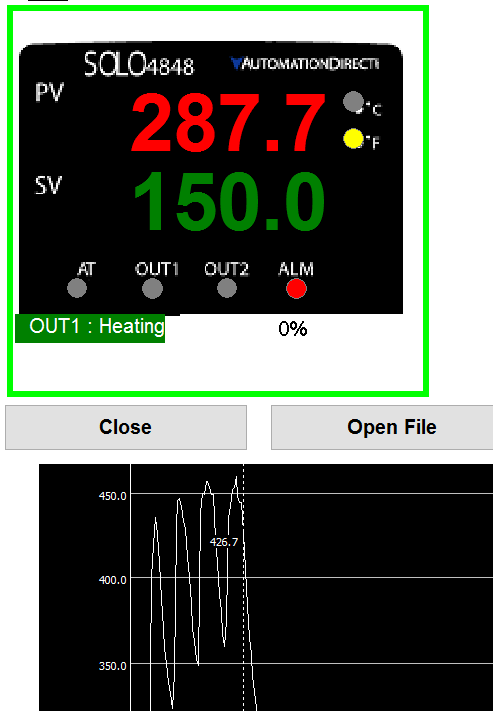

Temp in center of the wick

OK, so I stuck the sensor into the middle of the wick, pushed in so the tip of the sensor is inserted to the middle of the coil lengthwise.

So this is the temp the juice sees in the middle of the wick:

- Normal 3 sec puffs

- Same 400 degree TC setting

- 1st puff the center of the wick only got up to 252 degrees.

- Successive puffs kept the wick temp rising

- Also, if you increase the puff length, the center of the wick continues to rise.

- It would appear that juice inside the wick does not get heated as hot as the coil.

- With single hits the wick stays pretty cool, but with chain hits the wick approaches the coil temp. TC only limits the coil temp, but the wick temp is not being directly controlled.

Effects of wick saturation

Ok, so all of my tests were done with the juice control wide open to ensure good wick saturation

At 15watts with juice flow wide open:

At 15watts with juice flow closed down (note, not a dry, or even bad tasting hit):

At 20 watts with juice control throttled back:

The 2nd and 3rd hits tasted slightly burnt to me, not dry hits. So I would say that yes, I taste "something" when you get over 500 degrees.

Not going to push the wattage up anymore as the insulation of the sensor cant handle any hotter.

I didnt do a screen capture of it but at 15w the wick center maxed out at about 400 degrees after several chains vapes. The temp was still increasing slightly with each chain hit, but the ROR (rate of rise) with each hit had almost leveled out. I quit after about 6 hits.

So, some conclusions:

- Coil temp did coincide with DNA board setting at 400F.

- Chain vaping in wattage mode clearly increased temp with each hit

- Longer hits in wattage mode clearly increased temp

- Less air or juice flow clearly increased temp in wattage mode

- I personally didnt taste anything "bad" until over 500 degrees, but it was detectable above that point

- Under normal vaping (not chain), the center of the wick was considerably cooler than the coil

- Depending on the coil/juice/air it doesnt take much wattage to get over 400 degrees, and I didnt taste anything bad until you hit 500.

Specifically, I could not "taste" the area highlighted in yellow below.

© Wang

©2017 Mike Petro. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.