Hello! I've been vaping for a year now without serious involvement with the community excluding local shop interaction. I'm in Oklahoma, El Reno in specific, and I've got a rather technical background. I'll keep my comments to vaping.

I'm very electrically and mechanically inclined, and got introduced to vaping through making custom flashlights. Most serious flashlights use the 18650 and I stumbled onto vaping through the common battery usage. Odd, right? Well, I'd been smoking about half a pack a day at that point and I figured I'd give it a try. After doing a bit of research I decided I would give making one a shot. I decided to make a simple dripping rba. I hopped on my lathe and made a one piece dripper that connected straight to the battery, threaded to one of the flashlight housings I made. Using the momentary switch it had, I essentially made a mechanical mod. I went to the not-so-near vape shop and picked up some nichrome and silica, and set up a pretty darn good dripper from what they told me. Not bad for my first try. Come December '12 I gave the setup to a fellow wanting-to-quit smoker and as far as I'm aware they're a happy vaper. I gave it away because I went and pre-ordered the Tesla. During the preorder time, a different friend of mine let me borrow their eGo 1100 and a good ol' CE4. It kept me going, you know? The Telsa was/is great, and I have (nearly) no complaints. I just wish I had the jet black version.

I gave it away because I went and pre-ordered the Tesla. During the preorder time, a different friend of mine let me borrow their eGo 1100 and a good ol' CE4. It kept me going, you know? The Telsa was/is great, and I have (nearly) no complaints. I just wish I had the jet black version.  I typically use a AGA T2 or Nautilus now, the latter giving me problems and making me want to stay away from silica forever(suggestions welcome). Well, here it is now the end of July, and the itch for something new is strong. I'm drawing up a mechanical mod with the design criteria of having an extremely low voltage drop, as I find it rather dumb to have a great Li-Ion battery not being used to its full potential.

I typically use a AGA T2 or Nautilus now, the latter giving me problems and making me want to stay away from silica forever(suggestions welcome). Well, here it is now the end of July, and the itch for something new is strong. I'm drawing up a mechanical mod with the design criteria of having an extremely low voltage drop, as I find it rather dumb to have a great Li-Ion battery not being used to its full potential.  Think 1/4" solid copper contacts, possibly gold plated for the primary switch contacts, multipoint switch contact, and a springless holding system. (quarter turn tensioning, etc) The design will probably slightly resemble the good ol' GG side firing mech mod. Potential materials would be Titanium, 316L, Copper, Brass...

Think 1/4" solid copper contacts, possibly gold plated for the primary switch contacts, multipoint switch contact, and a springless holding system. (quarter turn tensioning, etc) The design will probably slightly resemble the good ol' GG side firing mech mod. Potential materials would be Titanium, 316L, Copper, Brass...

I don't really have much to ask at the moment, but I have a rather extensive electrical and mechanical background. I am almost done with my electrical engineering degree. This summer I've been doing a lot of heavy weight mechanical designs as well as control system design for them. Busy busy busy. Though, school is about to start up again and I'll have access to the machine shop again to create this beauty.

Vape on.

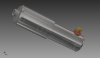

I'm very electrically and mechanically inclined, and got introduced to vaping through making custom flashlights. Most serious flashlights use the 18650 and I stumbled onto vaping through the common battery usage. Odd, right? Well, I'd been smoking about half a pack a day at that point and I figured I'd give it a try. After doing a bit of research I decided I would give making one a shot. I decided to make a simple dripping rba. I hopped on my lathe and made a one piece dripper that connected straight to the battery, threaded to one of the flashlight housings I made. Using the momentary switch it had, I essentially made a mechanical mod. I went to the not-so-near vape shop and picked up some nichrome and silica, and set up a pretty darn good dripper from what they told me. Not bad for my first try. Come December '12 I gave the setup to a fellow wanting-to-quit smoker and as far as I'm aware they're a happy vaper.

I typically use a AGA T2 or Nautilus now, the latter giving me problems and making me want to stay away from silica forever(suggestions welcome). Well, here it is now the end of July, and the itch for something new is strong. I'm drawing up a mechanical mod with the design criteria of having an extremely low voltage drop, as I find it rather dumb to have a great Li-Ion battery not being used to its full potential.

I typically use a AGA T2 or Nautilus now, the latter giving me problems and making me want to stay away from silica forever(suggestions welcome). Well, here it is now the end of July, and the itch for something new is strong. I'm drawing up a mechanical mod with the design criteria of having an extremely low voltage drop, as I find it rather dumb to have a great Li-Ion battery not being used to its full potential.  Think 1/4" solid copper contacts, possibly gold plated for the primary switch contacts, multipoint switch contact, and a springless holding system. (quarter turn tensioning, etc) The design will probably slightly resemble the good ol' GG side firing mech mod. Potential materials would be Titanium, 316L, Copper, Brass...

Think 1/4" solid copper contacts, possibly gold plated for the primary switch contacts, multipoint switch contact, and a springless holding system. (quarter turn tensioning, etc) The design will probably slightly resemble the good ol' GG side firing mech mod. Potential materials would be Titanium, 316L, Copper, Brass...I don't really have much to ask at the moment, but I have a rather extensive electrical and mechanical background. I am almost done with my electrical engineering degree. This summer I've been doing a lot of heavy weight mechanical designs as well as control system design for them. Busy busy busy. Though, school is about to start up again and I'll have access to the machine shop again to create this beauty.

Vape on.

Would love to see a pic of your first mod if you got one.

Would love to see a pic of your first mod if you got one.