A while back bapgood got me started on CADing mod designs, so I started playing with a concept for a 3D printed bottom feeder. He was nice enough to lend me some of the elements he used for his SXS to get me going. (So a big Hat Tip to baps). The objective here was to get a squonker design in the smallest amount of space possible. While squeezing in a DNA chip between the juice and battery compartments was a challenge, the toughest part of the design was to get all the wiring connections aligned and into a top cap that was removable for battery changes and juice refills. The mod holds an 18650 and 6ml juice bottle and a number of parts came from MiikePetro and Tibs' co-op but are readily sourced on line. (Faddydaddy 510, copper disc, screws, spring, etc.) The mod has seven printed parts: the body, the base cap, the top cap, the button, an internal removable spacer for the battery compartment and a small positioning piece and a firing pin for the mini tact switch. The juice bottle compartment is fully sealed off in the body from the DNA chip and the battery.

Dimensions are 3.5 x 1.9 X .87. Here is a comparison to Tibs for size.

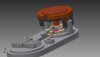

Rough layout for parts and wiring.

Painted and partial assembly.

Magnets, spring pin connectors and terminal turrets installed.

It works!

Final assembly.

One thing I noticed is that the shapeway material while durable and strong, can deform. The top cap started out flush to the body, but after a lot of handling and probably from the counter pressure from the battery spring, the material bowed out about half millimeter. I swapped out the spring with a much softer one and the top relaxed a bit. I think the big win here was that the spring pin connectors and terminal turrets held power all the way up to 30 watts. I wasnt certain, even though the spring pins are rated to 20 amps, that at the actual connection point to the turrets they wouldnt get hot enough to melt the plastic. So far so good.

This is a first prototype. The build works, its noticeably light and holds well in the hand, but like anything else, going through the actual build from a design on paper, a lot of improvements/changes become more obvious. So this is prototype #1. Prototype #2 (major redesign) is on order and prototype #3 is being finalized.

Dimensions are 3.5 x 1.9 X .87. Here is a comparison to Tibs for size.

Rough layout for parts and wiring.

Painted and partial assembly.

Magnets, spring pin connectors and terminal turrets installed.

It works!

Final assembly.

One thing I noticed is that the shapeway material while durable and strong, can deform. The top cap started out flush to the body, but after a lot of handling and probably from the counter pressure from the battery spring, the material bowed out about half millimeter. I swapped out the spring with a much softer one and the top relaxed a bit. I think the big win here was that the spring pin connectors and terminal turrets held power all the way up to 30 watts. I wasnt certain, even though the spring pins are rated to 20 amps, that at the actual connection point to the turrets they wouldnt get hot enough to melt the plastic. So far so good.

This is a first prototype. The build works, its noticeably light and holds well in the hand, but like anything else, going through the actual build from a design on paper, a lot of improvements/changes become more obvious. So this is prototype #1. Prototype #2 (major redesign) is on order and prototype #3 is being finalized.