You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Subtank RBA builds? show em!

- Thread starter jlwiseman

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

slm" data-source="post: 17574374" class="bbCodeBlock bbCodeBlock--expandable bbCodeBlock--quote js-expandWatch">slm said:

Thx slm. Nice to see you hangin' in there. The build's the twisted lead parallel which warranted a highlight on my blog page...How about a compromise? Tensioned twisted-lead parallels! An advanced search with those terms on the forum should turn up a couple'a dozen entries devoted to makin' it and why.

It'll also turns up this entry from Jun 2014 Japanese Organic Cotton Pads about chunky wicking, a term I coined later. Point being I've been arguing maxing out wetted wire surface and the wick to go with it for quite some time, years. While folks were still talkin' <1.5mm micro's and thin wicks. My view since I started workin' strain into the Protank in 2013 has been to use as much capacity as the geometry of the atomizer will effectively support. Let variable wattage and airflow (tips, afc) do their job. So that meant larger coils stuffed adequately (short of throttling flow). A concept Kanger took to the limits with its introduction of the Subtank, ultimately.

The twisted lead parallel above is the evolution of that idea of maximum vaporizing contact area. The most stable coil I've ever done. Love parallels but they can warp and distort easily as higher power is applied. Strain winding them imparts the symmetry to stabilize them during oxidation; however, it's the twisted leads that keep them locked in place and incredibly stable. Not a beginners build and like anything more complex than single wire requires some experience with the result. The wind can be made to run cool or hot, low power or high power. If not strain wound tho, they will tend to go hot. So you get a diffusion effect at relatively low wattage as you might on a multi-wire wind at much higher power, if you like that vape. You still do get the stabilizing effect of the leads to help keep the coil itself coherent.

LMK if you try these or have questions. Post pictures!

Good luck.

Last edited:

Got my toys today

I fiddled with the ugly first coil I posted yesterday until the wraps were spaced out as evenly as I could get them and gave it a try. I don't have much to compare it to since this is my first mod & tank, but after a harsh start with super hot vapor on really low temps (not sure what was going on there but the resistance of my coil also dropped from 0,47 to 0,38, I suspect it wasn't really at room temperature yet when I first locked the resistance) it is vaping beautifully now.

The TC makes it real easy to dial in the temp so it's not too hot yet produces lots of flavor and vapor. I got a few more RBA deks in too and these have the larger juice holes (I'm using the plus right now that came with the tank, new ones are plus V2 if I'm not mistaken) so I'll paly with those for a bit and see if I can make a more even coil and a slightly tighter fitting wick, but for now I'm gonna keep on fogging the place up for a bit

I fiddled with the ugly first coil I posted yesterday until the wraps were spaced out as evenly as I could get them and gave it a try. I don't have much to compare it to since this is my first mod & tank, but after a harsh start with super hot vapor on really low temps (not sure what was going on there but the resistance of my coil also dropped from 0,47 to 0,38, I suspect it wasn't really at room temperature yet when I first locked the resistance) it is vaping beautifully now.

The TC makes it real easy to dial in the temp so it's not too hot yet produces lots of flavor and vapor. I got a few more RBA deks in too and these have the larger juice holes (I'm using the plus right now that came with the tank, new ones are plus V2 if I'm not mistaken) so I'll paly with those for a bit and see if I can make a more even coil and a slightly tighter fitting wick, but for now I'm gonna keep on fogging the place up for a bit

I, have made fire!!

lol

I was getting tired of the taste of my blueberry cheesecake so I rinsed out the tank, re-wicked, and went for some strawberry instead.

But I guess I wasn't careful enough when re-wicking and moved the coil around a bit too much. When I'd put everything back together it read only 0,08ohm (instead of 0,38). Silly me tried to fire it anyway and boom, my tank lit up!

When I pulled it apart one leg of the coil was gone for the most part but everything seemed fine otherwise, even the cotton looked brand new.

Anyway, I was about to go to bed and didn't feel like wrapping a new coil just now so I decided to grab one of the spare RBAs with the factory coil still in it, wick it and try the VW mode on my new mod instead. I do not like it! lol

It spits at me, is slow on start up and when it does get to temp it is really harsh and I get barely any flavor even at a mere 9 watts.

I do get a lot more and denser vapor now though. Could it be that it's just the juice (first juice was 65/35vg/pg, this one is 100%vg), or does putting in more wick in a more even coil result in this difference in vapor production?

I'm vaping this 0,5ohm Kanthal coil @ 9W while I was @ 215 degrees Celsius/420F on TC if that means anything to anyone.

Anyways, can't wait to roll a new Ti coil and get my TC back tomorrow, lmao.

lol

I was getting tired of the taste of my blueberry cheesecake so I rinsed out the tank, re-wicked, and went for some strawberry instead.

But I guess I wasn't careful enough when re-wicking and moved the coil around a bit too much. When I'd put everything back together it read only 0,08ohm (instead of 0,38). Silly me tried to fire it anyway and boom, my tank lit up!

When I pulled it apart one leg of the coil was gone for the most part but everything seemed fine otherwise, even the cotton looked brand new.

Anyway, I was about to go to bed and didn't feel like wrapping a new coil just now so I decided to grab one of the spare RBAs with the factory coil still in it, wick it and try the VW mode on my new mod instead. I do not like it! lol

It spits at me, is slow on start up and when it does get to temp it is really harsh and I get barely any flavor even at a mere 9 watts.

I do get a lot more and denser vapor now though. Could it be that it's just the juice (first juice was 65/35vg/pg, this one is 100%vg), or does putting in more wick in a more even coil result in this difference in vapor production?

I'm vaping this 0,5ohm Kanthal coil @ 9W while I was @ 215 degrees Celsius/420F on TC if that means anything to anyone.

Anyways, can't wait to roll a new Ti coil and get my TC back tomorrow, lmao.

Thanks! I need to devote a week to reading all your information!Thx SLM. Nice to see you hangin' in there. The build's the twisted lead parallel which warranted a highlight on my blog page...How about a compromise? Tensioned twisted-lead parallels! An advanced search with those terms on the forum should turn up a couple'a dozen entries devoted to makin' it and why.

It'll also turns up this entry from Jun 2014 Japanese Organic Cotton Pads about chunky wicking, a term I coined later. Point being I've been arguing maxing out wetted wire surface and the wick to go with it for quite some time, years. While folks were still talkin' <1.5mm micro's and thin wicks. My view since I started workin' strain into the Protank in 2013 has been to use as much capacity as the geometry of the atomizer will effectively support. Let variable wattage and airflow (tips, afc) do their job. So that meant larger coils stuffed adequately (short of throttling flow). A concept Kanger took to the limits with its introduction of the Subtank, ultimately.

The twisted lead parallel above is the evolution of that idea of maximum vaporizing contact area. The most stable coil I've ever done. Love parallels but they can warp and distort easily as higher power is applied. Strain winding them imparts the symmetry to stabilize them during oxidation; however, it's the twisted leads that keep them locked in place and incredibly stable. Not a beginners build and like anything more complex than single wire requires some experience with the result. The wind can be made to run cool or hot, low power or high power. If not strain wound tho, they will tend to go hot. So you get a diffusion effect at relatively low wattage as you might on a multi-wire wind at much higher power, if you like that vape. You still do get the stabilizing effect of the leads to help keep the coil itself coherent.

LMK if you try these or have questions. Post pictures!

Good luck.

I currently have a triple tight twisted 30G .45 ohm coil in my V1 deck and a 1 ohm 28/34 Clapton in a V2. Definitely nothing near as fancy as that coil! I'm going to read up on how to do it and give it a go.

Thanks! I need to devote a week to reading all your information!

I currently have a triple tight twisted 30G .45 ohm coil in my V1 deck and a 1 ohm 28/34 Clapton in a V2. Definitely nothing near as fancy as that coil! I'm going to read up on how to do it and give it a go.

My go to for the better part of the past three years was twisted for high power. Until…the means to stabilize parallels became clear. If you like the fast-firing high contact surface area of parallels the downside has been durability due to susceptibility to distortion. Strain winding will give you the best chance at uniform oxidation. Twisted leads will lock that in place. It's a great build to have in your kit. Tag me if needed.

Good luck!

Alright, titanium coil number 2:

Still a bit crooked but slightly less crooked than number 1, lol

This one comes in at 0,31ohm. I wicked it much better though, clouds are now as dense as with the factory Kanthal coil.

Still a bit crooked but slightly less crooked than number 1, lol

This one comes in at 0,31ohm. I wicked it much better though, clouds are now as dense as with the factory Kanthal coil.

Alright, titanium coil number 2:

Still a bit crooked but slightly less crooked than number 1, lol

This one comes in at 0,31ohm. I wicked it much better though, clouds are now as dense as with the factory Kanthal coil.

Save you some time. I don't think Ti does well as a contact coil (if it fired at all, that must be very low res). By now you've prolly seen it goes quite hot, if it did. Better to build it as tight close spaced coil. Rather than torching it which I don't recommend, you can use strain to create the geometry neatly by winding on a screw. To fill that 9mm of post-to-post spread and maximize contact surface without skewing you've got to use Kanthal. It builds an alumina oxide surface insulating layer which allows for contact without shorting when properly developed by low voltage pulsing. For that you need very uniform contact and consistent turn to turn strain as demonstrated in post #422.

Good luck and shout out if needed.

Save you some time. I don't think Ti does well as a contact coil (if it fired at all, that must be very low res). By now you've prolly seen it goes quite hot, if it did. Better to build it as tight close spaced coil. Rather than torching it which I don't recommend, you can use strain to create the geometry neatly by winding on a screw. To fill that 9mm of post-to-post spread and maximize contact surface without skewing you've got to use Kanthal. It builds an alumina oxide surface insulating layer which allows for contact without shorting when properly developed by low voltage pulsing. For that you need very uniform contact and consistent turn to turn strain as demonstrated in post #422.

Good luck and shout out if needed.

I'm trying to stay as close to 0,4 to 0,5ohm as I can get so that doesn't leave me enough room to have a spaced out coil with 26g on this little RBA. I've ordered some 28g though (thinnest I could find locally, I would have preferred 30g), to give myself a bit more room to play without going too low in resistance.

I want to use TC so Kanthal isn't an option, plus I didn't like the taste of it when I tried it.

Not sure what you mean with it getting hot though, it gets as hot as I set the temperature to? Resistance is 0,31 ohm on this one.

I don't torch or dry-burn ti by the way. I sand it lightly, then rinse with hot water, roll, wick, and vape

I'm trying to stay as close to 0,4 to 0,5ohm as I can get so that doesn't leave me enough room to have a spaced out coil with 26g on this little RBA. I've ordered some 28g though (thinnest I could find locally, I would have preferred 30g), to give myself a bit more room to play without going too low in resistance.

I want to use TC so Kanthal isn't an option, plus I didn't like the taste of it when I tried it.

Not sure what you mean with it getting hot though, it gets as hot as I set the temperature to? Resistance is 0,31 ohm on this one.

I don't torch or dry-burn ti by the way. I sand it lightly, then rinse with hot water, roll, wick, and vape

OTA, looks like you're well on your way tryin' the Ti thing. If I picked up on that I wouldnt have posted the parallel pic. Prolly too much for this tank unless you go very thin. Some thoughts tho.

If you're tasting Kanthal, it isn't properly oxidized. The alumina layer's essentially ceramic. That's the process I introduced, oxidizing Kanthal. Prior to this everyone was torching Kanthal to form wire which changes its flavor output. The ceramic layer is neutral. To my taste quite close to stainless, even as I can taste food cooked in stainless, it's far more subtle in a vape. You'll have to decide for yourself if TC and stainless are worth the cost in time and effort. I can produce KA1 winds in 30 sec's or less, it's drop-and-go after oxidizing which takes a few pulses inside of a few minutes. And I encourage new users to learn that baseline. Otherwise, how do we know what tastes or performs better or best?

As you note, the res you build to determines your output temp. However, if you short wire it will go hot in operation. You're no longer dealing with the theoretical linear spec of res for a given length of wire. You've changed that by giving electrons an alternative exit path. A shorter one. Less wire, less res, more heat. And progressively so with more power. That's what I was referring to. It's not a stable wind or the resulting temp predictable. The short will be an annoyance I suppose if it cuts firing off too quickly (shortens fire time). Haven't experimented with shorting TC to say. I think my conclusion's confirmed on the TC threads. Contact's not desirable for TC reg devices.

Typical Mini build for me is 25/7/7 2.7051mmØ LL=9mm t.m.c. @ 0.7905Ω producing ~17-22W (3.7-4.2V). Of course you can push these out further but I'll add wire mass Ø say 2.28mm, as I want more production. This build generates a lot of density which you can then diffuse by more airflow, AFC drip tip and draw style. Want more, add watts. It's purposely a density build based on the geometry of this device and the sweet spot for most of the variable mods I have in the mix.

What can I add. The (inner) spread on the ST RDA is about 2.8mm. You can build out to ~3.0mm without appreciably skewing the end turns. The splaying inwards creates pressure points (or absence of strain, looser) which can result in variations in temp as well. Then one end of the coil may be hotter than the other. Won't be a functional micro then anyway (not firing inside out). Properly oxidized (tensioned) Kanthal fire fairly uniformly end-to-end. Usually, spinnin' just the number of winds to avert skew of the end tuns is usually enough as a guideline to ensure a dry burn of about 1200F at 4-6 sec's (red surface color temp roughly) on a fresh 4.2V (n.b. wind with too much strain and this will go hotter, perhaps even leads). And that is more than adequate for a very solid vape. Insofar as temp, your target as normal by varying turn count and overall diameter.

Defintely try Ti and Kanthal along with if you like. I'll help as I can maxing out the latter. Def recommend.

Good luck!

Last edited:

OTA, looks like you're well on your way tryin' the Ti thing. If I picked up on that I wouldnt have posted the parallel pic. Prolly too much for this tank unless you go very thin. Some thoughts tho.

If you're tasting Kanthal, it isn't properly oxidized. The alumina layer's essentially ceramic. That's the process I introduced, oxidizing Kanthal. Prior to this everyone was torching Kanthal to form wire which changes its flavor output. The ceramic layer is neutral. To my taste quite close to stainless, even as I can taste food cooked in stainless, it's far more subtle in a vape. You'll have to decide for yourself if TC and stainless are worth the cost in time and effort. I can produce KA1 winds in 30 sec's or less, it's drop-and-go after oxidizing which takes a few pulses inside of a few minutes. And I encourage new users to learn that baseline. Otherwise, how do we know what tastes or performs better or best?

As you note, the res you build to determines your output temp. However, if you short wire it will go hot in operation. You're no longer dealing with the theoretical linear spec of res for a given length of wire. You've changed that by giving electrons an alternative exit path. A shorter one. Less wire, less res, more heat. And progressively so with more power. That's what I was referring to. It's not a stable wind or the resulting temp predictable. The short will be an annoyance I suppose if it cuts firing off too quickly (shortens fire time). Haven't experimented with shorting TC to say. I think my conclusion's confirmed on the TC threads. Contact's not desirable for TC reg devices.

Typical Mini build for me is 25/7/7 2.7051mmØ LL=9mm t.m.c. @ 0.7905Ω producing ~17-22W (3.7-4.2V). Of course you can push these out further but I'll add wire mass Ø say 2.28mm, as I want more production. This build generates a lot of density which you can then diffuse by more airflow, AFC drip tip and draw style. Want more, add watts. It's purposely a density build based on the geometry of this device and the sweet spot for most of the variable mods I have in the mix.

What can I add. The (inner) spread on the ST RDA is about 2.8mm. You can build out to ~3.0mm without appreciably skewing the end turns. The splaying inwards creates pressure points (or absence of strain, looser) which can result in variations in temp as well. Then one end of the coil may be hotter than the other. Won't be a functional micro then anyway (not firing inside out). Properly oxidized (tensioned) Kanthal fire fairly uniformly end-to-end. Usually, spinnin' just the number of winds to avert skew of the end tuns is usually enough as a guideline to ensure a dry burn of about 1200F at 4-6 sec's (red surface color temp roughly) on a fresh 4.2V (n.b. wind with too much strain and this will go hotter, perhaps even leads). And that is more than adequate for a very solid vape. Insofar as temp, your target as normal by varying turn count and overall diameter.

Defintely try Ti and Kanthal along with if you like. I'll help as I can maxing out the latter. Def recommend.

Good luck!

I did forget to dry burn the Kanthal coil before use, are you trying to tell me that's what caused the metallic taste with that one?

I must admit I sometimes have a hard time understanding your English for some reason..

The coil in my last photo (it's a 3mm ID by the way, I did my best to max out the space that this little RBA gives me) has been working fine fine albeit it could be a little harsher then the first one, but I'm not a 100% sure about that. The first one was wicked very loosely so that one underperformed a bit anyway, plus I'm using a different juice now which also affected the experience much more than I anticipated.

I'll try a more spaced out coil tomorrow when my 28g wire comes in while keeping everything else the same and report back again.

I'm not a 100% certain how to interpenetrate this by the way: 25/7/7 2.7051mmØ LL=9mm t.m.c. @ 0.7905Ω

Would that be 7 wraps of 25 gauge @ 2,7mm ID with 9mm legs resulting in a 0,8 ohm resistance..? I'm still missing a '7' there though, what does the second 7 after the 25 stand for?

I'm gonna stick to titanium for now, but I'll experiment with Kanthal and SS a bit more once I got my bearings down. I think it'll get to confusing otherwise, it is a lot to take in for newbie.

Thanks for the thorough reply anyhoe, I really appreciate the time you put in your posts

LOL, you're following quite well. Yep on the Kanthal. Bare metal Kanthal is not tasty. Pin vise tension winding I highly recommend to ensure thorough oxidation and insulation (stop short). Then Kanthal is ideal. It IS heating element wire. Kinda silly I guess to state the obvious. All else is experimental including high tech TC with us as the guinea pigs. A stable tensioned KA1 micro/mini/macro coil will run with the best of them. When you're ready to try and wind one OTA give a shout. Really glad to help. On the Ti, all feedback is appreciated by those trying to struggle through as you know.

On 7/7, it's simply a "full wrap" (legs opposing) vs. a half-wrap, 7/6. You're trackin' great.

Not to worry, take your time. For most it's a months long process not only with the tech but gear selection. I feel the t.m.c. can shorten that to weeks as easy to make, repeatable and cheap. Adaptable to any gear.

Good luck again.

On 7/7, it's simply a "full wrap" (legs opposing) vs. a half-wrap, 7/6. You're trackin' great.

Not to worry, take your time. For most it's a months long process not only with the tech but gear selection. I feel the t.m.c. can shorten that to weeks as easy to make, repeatable and cheap. Adaptable to any gear.

Good luck again.

LOL, you're following quite well. Yep on the Kanthal. Bare metal Kanthal is not tasty. Pin vise tension winding I highly recommend to ensure thorough oxidation and insulation (stop short). Then Kanthal is ideal. It IS heating element wire. Kinda silly I guess to state the obvious. All else is experimental including high tech TC with us as the guinea pigs. A stable tensioned KA1 micro/mini/macro coil will run with the best of them. When you're ready to try and wind one OTA give a shout. Really glad to help. On the Ti, all feedback is appreciated by those trying to struggle through as you know.

On 7/7, it's simply a "full wrap" (legs opposing) vs. a half-wrap, 7/6. You're trackin' great.

Not to worry, take your time. For most it's a months long process not only with the tech but gear selection. I feel the t.m.c. can shorten that to weeks as easy to make, repeatable and cheap. Adaptable to any gear.

Good luck again.

I guess I'm getting there

Thanks for the reassurance and clarification!

I tend to be a bit obsessive when something really interests me so hopefully I'll get there a little bit quicker then months, haha, but we'll see, we're never done learning anyway

And number 3, I'm actually a little bit proud of this one:

28g Ti, 7 and a little bit wraps @3mm ID, comes in @ 0,52ohm.

Just a few more questions @MacTechVpr;

-if there is a popping sound while taking a hit does this mean the wick is running dry or too wet?

-do you just measure the length from the screw to where the coil starts to get the accurate leg length, or do you have to factor in the entire length of wire that's wrapped around the screws as well?

28g Ti, 7 and a little bit wraps @3mm ID, comes in @ 0,52ohm.

Just a few more questions @MacTechVpr;

-if there is a popping sound while taking a hit does this mean the wick is running dry or too wet?

-do you just measure the length from the screw to where the coil starts to get the accurate leg length, or do you have to factor in the entire length of wire that's wrapped around the screws as well?

And number 3, I'm actually a little bit proud of this one:

28g Ti, 7 and a little bit wraps @3mm ID, comes in @ 0,52ohm.

Just a few more questions @MacTechVpr;

-if there is a popping sound while taking a hit does this mean the wick is running dry or too wet?

-do you just measure the length from the screw to where the coil starts to get the accurate leg length, or do you have to factor in the entire length of wire that's wrapped around the screws as well?

Popping usually means a dry or drying wick, common when you're breaking in cotton. You're wicking might be a bit on the thin side for such a thick i.d. This resembles a factory coil which produces a very diffuse airy and hot vape. It also cakes quickly at the top if you throw power at it. Over saturation will produce popping as well when hot juices spit out of the wick to strike the surface of the hotter outside surface of the coil. Usually these sizzle. That won't be your issue here.

I'd suggest taking it down a notch. Try a 7/64" screwdriver and wind as tightly as you can by hand. If they go contact, separate them carefully to as even and as close a spacing as possible. The goal, to line up end-turns as directly with the posts as possible. The symmetry will help with uniform wick surface contact. Also then, match wicking to the wind by using as much as will comfortably fit in without distorting the turns. This should be a bit more than you're using now.

An alternative would be finding a screw that will give you 3mm width and 2.5-2.75mm i.d. If you have a 7/64 shank screwdriver or drill bit compare that to any screws you might have, machine screw or other. Clamp it in a vice grips and wind tightly. You will come close to a full contact coil in terms of strain. The advantage is that turns won't tend to bunch together as when you try to tension wind a spaced coil or some other pricey widget. Contact coils on the other hand are only practical if they really are full contact.

Finally, lead length is effectively the length of wire running from the point of lost contact with the element (or 0/180 deg vertical, bottom or top of end turn) and the point of first contact with the post (termination point). Since the span between the pos/neg posts is ~9mm we can figure 1/2 the total spread for the symmetrical full-wrap wind we're using here with the SubMini.

Tell you what, it's much easier to predict your wind's resistance and ultimate performance if you build tensioned micro's because the length is precisely known. You can achieve symmetry with open winds but the math gets a bit tricky and I don't want to have to start posting schematics and engineering app's. For the new vaper…t.m.c.'s rock.

Good luck OTA.

Popping usually means a dry or drying wick, common when you're breaking in cotton. You're wicking might be a bit on the thin side for such a thick i.d. This resembles a factory coil which produces a very diffuse airy and hot vape. It also cakes quickly at the top if you throw power at it. Over saturation will produce popping as well when hot juices spit out of the wick to strike the surface of the hotter outside surface of the coil. Usually these sizzle. That won't be your issue here.

I'd suggest taking it down a notch. Try a 7/64" screwdriver and wind as tightly as you can by hand. If they go contact, separate them carefully to as even and as close a spacing as possible. The goal, to line up end-turns as directly with the posts as possible. The symmetry will help with uniform wick surface contact. Also then, match wicking to the wind by using as much as will comfortably fit in without distorting the turns. This should be a bit more than you're using now.

An alternative would be finding a screw that will give you 3mm width and 2.5-2.75mm i.d. If you have a 7/64 shank screwdriver or drill bit compare that to any screws you might have, machine screw or other. Clamp it in a vice grips and wind tightly. You will come close to a full contact coil in terms of strain. The advantage is that turns won't tend to bunch together as when you try to tension wind a spaced coil or some other pricey widget. Contact coils on the other hand are only practical if they really are full contact.

Finally, lead length is effectively the length of wire running from the point of lost contact with the element (or 0/180 deg vertical, bottom or top of end turn) and the point of first contact with the post (termination point). Since the span between the pos/neg posts is ~9mm we can figure 1/2 the total spread for the symmetrical full-wrap wind we're using here with the SubMini.

Tell you what, it's much easier to predict your wind's resistance and ultimate performance if you build tensioned micro's because the length is precisely known. You can achieve symmetry with open winds but the math gets a bit tricky and I don't want to have to start posting schematics and engineering app's. For the new vaper…t.m.c.'s rock.

Good luck OTA.

Hi again

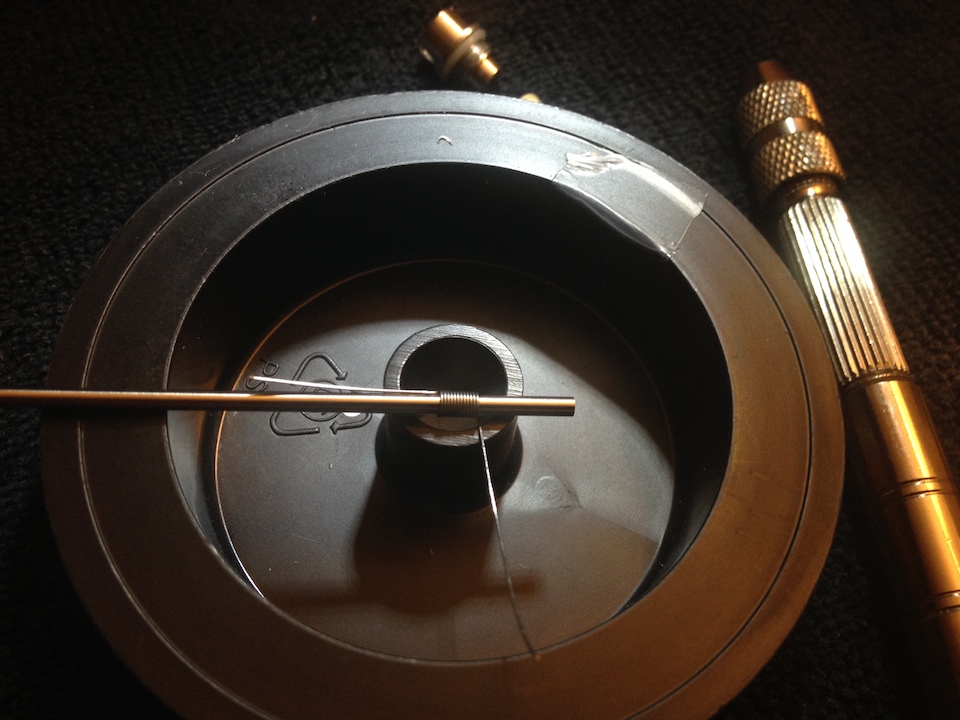

I was looking for a screw to wrap the coil on but the only ones I could find with the right diameter had pretty wide threads which would space the coil out too much so I just used the thingie I got on ebay again, one of these:

I was initially going for a 2,5mm inner diameter but I didn't put enough tension on the wire when wrapping so it ended up being 3mm anyway, lol. But I know I can make it tighter if I pull harder when rolling, I just was a bit careful today because the 28g wire felt so thin using it for the first time.

My preferred way right now is to clamp the wire in a vice and then roll that ^ thingie around while pulling on it to form a coil around it.

But if understand you correctly a smaller coil should give me more flavor? Or did you suggest a thinner coil only so the legs will line up better with the RBA's posts?

I'm not a high temp vaporist by the way. I usually start off around or just below 200 degrees Celsius in the morning and gradually up the temp a little as the day progresses. In general I don't get above 215 C which would be about 420 degrees in Fahrenheit.

So even more wick?! I thought I had already stuffed a lot in there this time!

I do like how this coil performs though, flavor and vapor production are pretty awesome at 215 C. It also seems more consistent in use then that second coil I made. But, I'm coming from an Ego-CC so I'm probably easily impressed.

I also played a bit more with Kanthal by the way. Flavor seemed pretty similar compared to Ti now that I gave it a proper burn in before I wicked it, but I do prefer TC for a more consistent vape. It's just easier and more user friendly in my limited experience. I'd love to try stainless as well but my mod doesn't support it in TC mode so I'll stick to Ti for now.

I'm tempted to try a twisted coil with the 28g TI next, but I guess it's easier to stick with a single wire until I perfected my technique enough..

Thanks again for your input

Hi again

I was looking for a screw to wrap the coil on but the only ones I could find with the right diameter had pretty wide threads which would space the coil out too much so I just used the thingie I got on ebay again, one of these:

I was initially going for a 2,5mm inner diameter but I didn't put enough tension on the wire when wrapping so it ended up being 3mm anyway, lol. But I know I can make it tighter if I pull harder when rolling, I just was a bit careful today because the 28g wire felt so thin using it for the first time.

My preferred way right now is to clamp the wire in a vice and then roll that ^ thingie around while pulling on it to form a coil around it.

But if understand you correctly a smaller coil should give me more flavor? Or did you suggest a thinner coil only so the legs will line up better with the RBA's posts?

I'm not a high temp vaporist by the way. I usually start off around or just below 200 degrees Celsius in the morning and gradually up the temp a little as the day progresses. In general I don't get above 215 C which would be about 420 degrees in Fahrenheit.

So even more wick?! I thought I had already stuffed a lot in there this time!

I do like how this coil performs though, flavor and vapor production are pretty awesome at 215 C. It also seems more consistent in use then that second coil I made. But, I'm coming from an Ego-CC so I'm probably easily impressed.

I also played a bit more with Kanthal by the way. Flavor seemed pretty similar compared to Ti now that I gave it a proper burn in before I wicked it, but I do prefer TC for a more consistent vape. It's just easier and more user friendly in my limited experience. I'd love to try stainless as well but my mod doesn't support it in TC mode so I'll stick to Ti for now.

I'm tempted to try a twisted coil with the 28g TI next, but I guess it's easier to stick with a single wire until I perfected my technique enough..

Thanks again for your input

Thanks for the feedback. And excellent bro. Yes, securing the wire in a vise and using a stepped mandrel is an outstanding way to do very precise controlled strain winding (for best control keep the wire length short, distance from vice to wind). Wind with just enough strain to effectively form the wire. For a contact coil, increase tension a little bit at a time as you add turns. You will sense the exact amount of strain required to keep the coil from unwinding — the "sticky" point or what I refer to as adhesion in other threads. It's not mechanical adhesion in physics terms…but practical closest contact. You added enough heat to alter the internal metallic structure and impart metal memory. For Ti using an appropriate screw as I mentioned will give you the symmetry you're looking for. I don't see it any easier to wind with strain from one metal to the next. Still the same approaches available. I use a pin vise for standard winding or a fixed vise for parallels. Kanthal is a lot less "springy" than Ti or SS but the latter I would think respond to strain at least as well as KA1. The point here being gaining symmetry is what gets us to the vape quickly and reliably. No guessing or fiddly with it. Keep it on the bit or mandrel (or of the same size so it just drops in tight. And as I mentioned, 30 seconds to this…

Too many mods to mention. And I vape everything from clearo's at 12W to very high power builds…straight wire, parallels and multi-wire. Couldn't do it without the ease afforded by the prudent use of strain in wind and installation. You are on your way there. Congrats.

Good luck.

p.s. More vapor, more flavor. You have to have an effective vaporization rate of juice to actually taste it. Not just add heat to the vapor comin' off the kettle. Big clouds don't necessarily mean big taste. But they certainly can! If you build for density. So no, smaller diameters won't necessarily yield that. You build for the capacity of the device. Fill 'er up.

Last edited:

Thanks for the feedback. And excellent bro. Yes, securing the wire in a vise and using a stepped mandrel is an outstanding way to do very precise controlled strain winding (for best control keep the wire length short, distance from vice to wind). Wind with just enough strain to effectively form the wire. For a contact coil, increase tension a little bit at a time as you add turns. You will sense the exact amount of strain required to keep the coil from unwinding — the "sticky" point or what I refer to as adhesion in other threads. It's not mechanical adhesion in physics terms…but practical closest contact. You added enough heat to alter the internal metallic structure and impart metal memory. For Ti using an appropriate screw as I mentioned will give you the symmetry you're looking for. I don't see it any easier to wind with strain from one metal to the next. Still the same approaches available. I use a pin vise for standard winding or a fixed vise for parallels. Kanthal is a lot less "springy" than Ti or SS but the latter I would think respond to strain at least as well as KA1. The point here being gaining symmetry is what gets us to the vape quickly and reliably. No guessing or fiddly with it. Keep it on the bit or mandrel (or of the same size so it just drops in tight. And as I mentioned, 30 seconds to this…

Too many mods to mention. And I vape everything from clearo's at 12W to very high power builds…straight wire, parallels and multi-wire. Couldn't do it without the ease afforded by the prudent use of strain in wind and installation. You are on your way there. Congrats.

Good luck.

p.s. More vapor, more flavor. You have to have an effective vaporization rate of juice to actually taste it. Not just add heat to the vapor comin' off the kettle. Big clouds don't necessarily mean big taste. But they certainly can! If you build for density. So no, smaller diameters won't necessarily yield that. You build for the capacity of the device. Fill 'er up.

Gotcha, I'll put it to practice, thanks again!

ps: your (image..?) link doesn't work, it gives an error if I click it. This is also the case with yours:

my image dont work? it shows on my end, I must be setting something wrong. new to the forums and image hosting links wont work, still trying to figure out the whole media section. lol EDIT: fixed it I think made a public album didnt realize my other albums were not oublic lol.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 14

- Views

- 4K

- Replies

- 1

- Views

- 556

- Replies

- 0

- Views

- 1K

- Replies

- 0

- Views

- 2K

- Replies

- 5

- Views

- 1K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)