I've recently switched to Framed Staple contact coils and I've been having issues getting my builds to last. As beautiful as they were, I was getting burnt hits on longer pulls and the resistance became erratic. I was changing the cotton (Cotton Bacon Prime) every single day and seeing scorches on it.

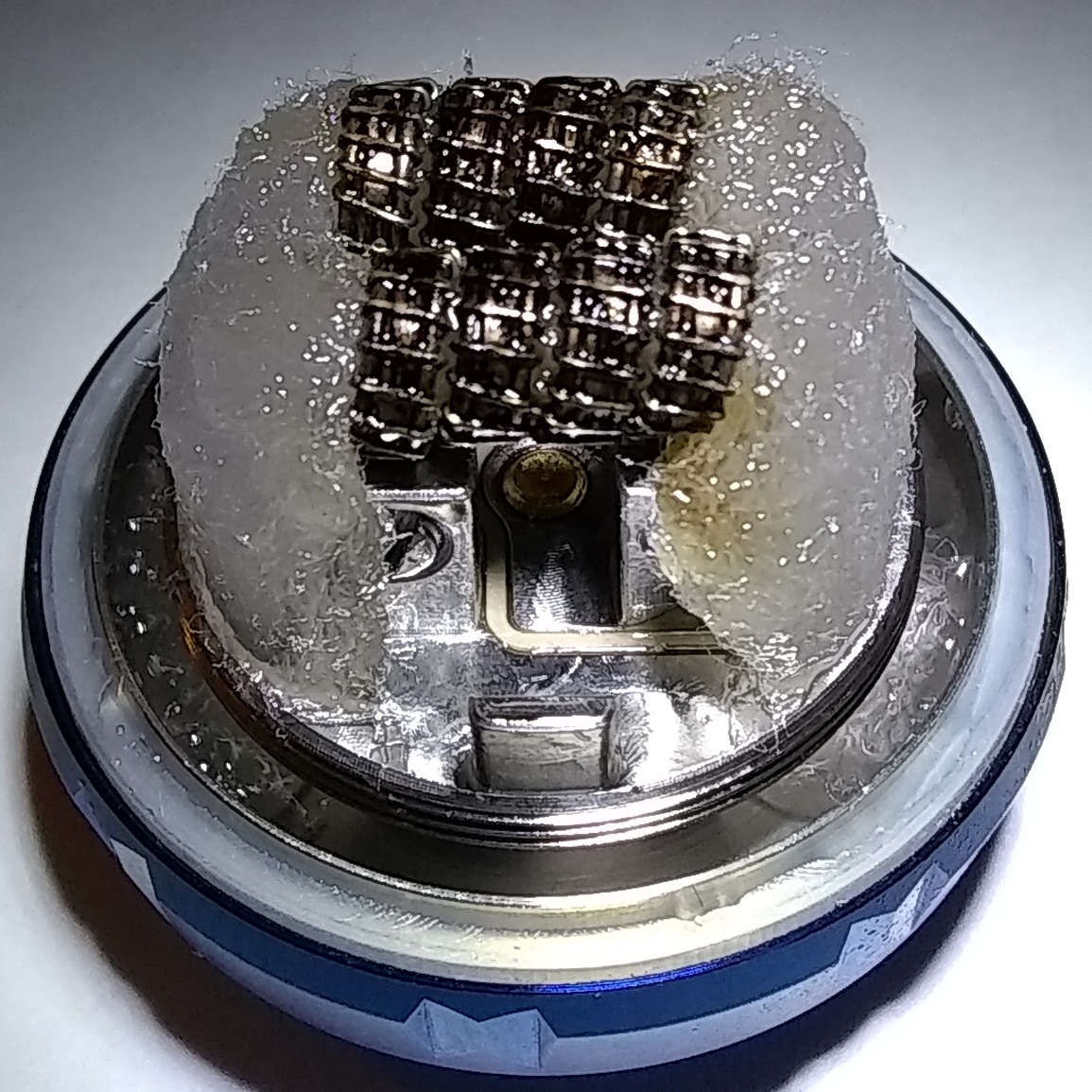

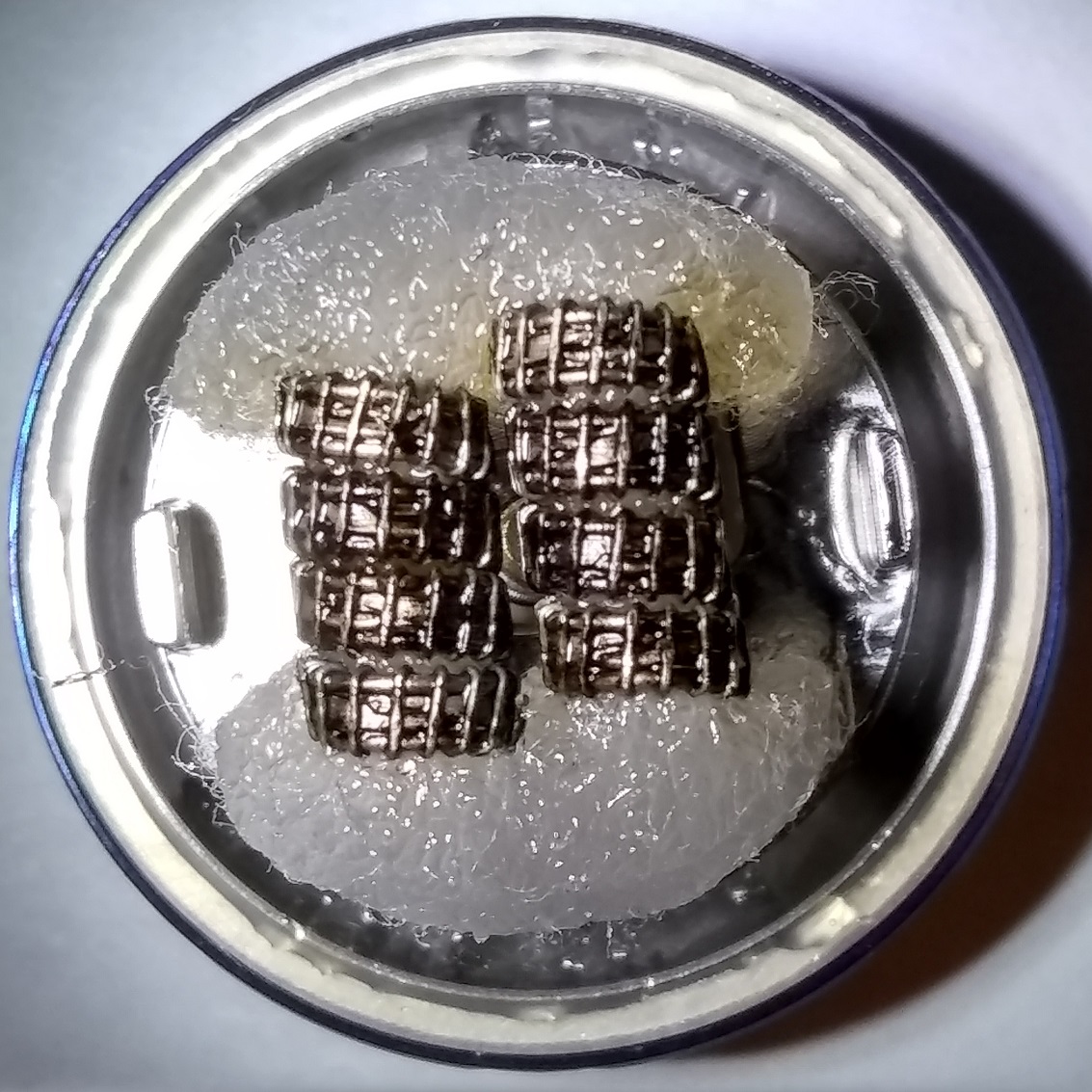

I ran this 3.5mm one at 150W:

And this 3mm one at 110W:

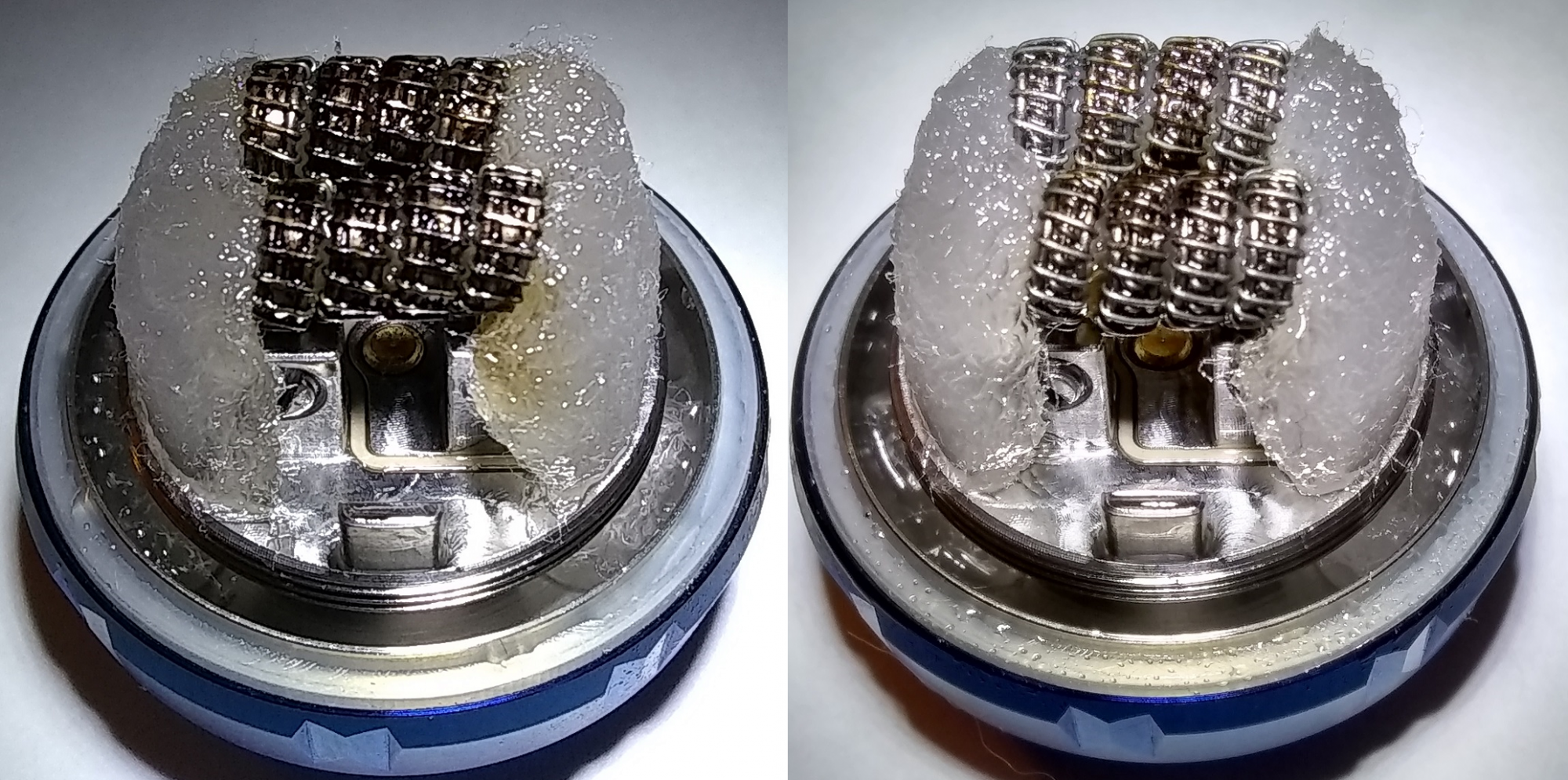

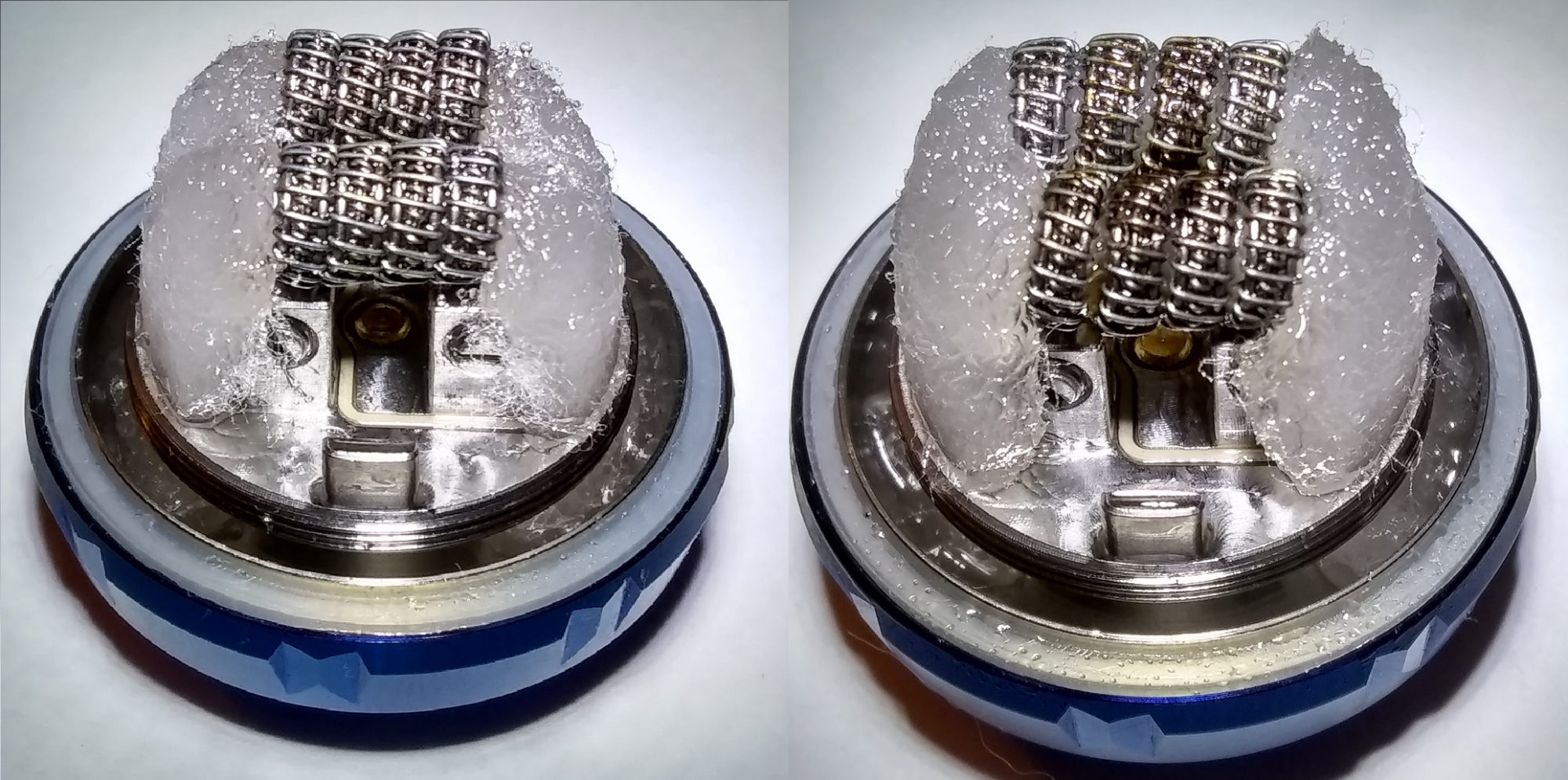

So I decided to stretch one into a spaced coil and it made a big difference. I run this 3mm one at 120W:

Notice the cotton visible between gaps.

The spaced coil build has so far outlasted the others with no noticeable performance degradation after 24 hours, and most importantly no dry hits (although the wick is a slightly discolored). The wick doesn't seem to burn easily when there are spaces between the wraps. I'm guessing that it doesn't dry out as severely due to extra juice in the gaps, which also serves to cool down the coils faster. And I can pack a bit more cotton in there too since it has room to expand.

I speculate that the resistance is more stable because there is no contact between wraps for electricity to bridge across.

You don't see a lot of talk about larger spaced coils. I only found one detailed comparison video (Youtube, 41min) discussing the topic. I'm curious to know what the community thinks about them.

I ran this 3.5mm one at 150W:

Saddle Horse Blues 0.11Ω ⌀3.5 Staggered Framed Staple Build on Zeus X

0.21ohm per coil \

26gN80 Frames \

36g/38gN80 - 3.5mm \

0.5mm K1 Ribbon x4

26gN80 Frames \

36g/38gN80 - 3.5mm \

0.5mm K1 Ribbon x4

Geekvape Framed Staple Contact 0.12Ω Dual Coil Build Side View

Geekvape F202 Framed Staple Fused Clapton Coil 4-wrap 0.25Ω x2 on Zeus X

So I decided to stretch one into a spaced coil and it made a big difference. I run this 3mm one at 120W:

Geekvape Framed Staple Spaced 0.1Ω Dual Coil Build Side View

Geekvape F202 Framed Staple Twisted Coil 4-wrap 0.2Ω x2 on Zeus X

Geekvape Framed Staple Spaced 0.1Ω Dual Coil Build Top View

Geekvape F202 Framed Staple Twisted Coil 4-wrap 0.2Ω x2 on Zeus X

The spaced coil build has so far outlasted the others with no noticeable performance degradation after 24 hours, and most importantly no dry hits (although the wick is a slightly discolored). The wick doesn't seem to burn easily when there are spaces between the wraps. I'm guessing that it doesn't dry out as severely due to extra juice in the gaps, which also serves to cool down the coils faster. And I can pack a bit more cotton in there too since it has room to expand.

I speculate that the resistance is more stable because there is no contact between wraps for electricity to bridge across.

You don't see a lot of talk about larger spaced coils. I only found one detailed comparison video (Youtube, 41min) discussing the topic. I'm curious to know what the community thinks about them.