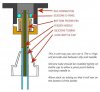

well I came up with a way to make these 510 connectors work great. I came up with a few different alternatives but the best one required me to drill out the plastic insulator to 3/16". was easy to do little by little with the drill bit by hand with no drill, I then inserted a 3/16" OD silicone hose into the barrel of the plastic insulator bottomed to the bottom stop. this silicone bushing is all that's needed, get the length right and just slip the needle in. the silicone has enough give that it allows the head of the needle to sit high enough to contact an atty before it is fully seated and allow the needle to compress and let any atty sit flush and absorb any discrepancies in length from different atties.

the silicone bushing is substantial and there is no chance of leaking as it's a snug enough fit to the outer wall of the insulator drilled to 3/16" and the 1/16" ID is perfect for the needle to slide through with just enough resistance that it can move yet is fully sealed too. I lubed it with vg as I assembled it and it works perfect, should be perfect and durable

I had this hose because this is the hose I use in all my bottom feeder builds as my feed tubes, it's also great to make soft insulators from. what I did was make the main silicone insert be slightly shorter than protruding from the top of the plastic insulator and then cut another small ring to use on the needle to bring it to final length... this allows me to insert the needle and check final adjustment that I can fine tune by simply removing the ring and making the final ring fatter or thinner until i get the right thickness that it works on several atties. once you trim it right it should work on all of your atties

heres a few pics

this is approx how high the final results will be, actually it's slightly less than this but to fine tune the length to perfect without having to keep removing and installing the main insert of this tube I cut it short of this and then add a ring that can be fine tuned easily as it will just slip in and out easily with the needle

cut short of the top so it has room to give for the separate adjusting ring

this is the size ring that works for me with the main insert cut as shown above

this thing will now make great contact with all my atties yet still let all my atties sit completely flush too and def no chance of leaks

this is the hose I used... this is enough to do well over 100 of these but it is good to have as feed tube hose and for insulators and stuff too. I use this hose all the time for insulating as well as feeding

White SiliconeTubing, 1/16"ID, 3/16"OD, 1/16" Wall, 10' Length: Industrial Rubber Tubing: Amazon.com: Industrial & Scientific