Hi all. I'd like to first thank all of you for this forum which has provided some very good reading over the past couple of weeks.

About a year ago I quit smoking cold turkey after having a first rib resectomy because of Paget-Schroetter disease. Fast forward about 7 months and I was back to smoking again when I was working a few months overnight. If I had done my research on this forum beforehand I probably would have avoided buying a ridiculously overpriced/underfeatured starter kit (I'll let you guess which one. ). Been vaping for a couple of weeks now.

). Been vaping for a couple of weeks now.

So, anywho... on to my current question.

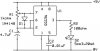

Most mods and vv batteries I've seen use linear voltage regulation. Nothing wrong with that, as so many probably have proved. I like to tinker with circuits though, and was looking at using pulse-width modulation to control power delivered to the atmoizer ("wattage"... am I the only one who doesn't like that term, lol). Basically, switching full voltage to the atmomizer quickly (68 kHz is easily done with a 555 multivibrator), at a duty cycle from 100% down to however low still manages to vaporize the e liquid. At 100% duty cycle (basically equivalent to a switch between the battery and atomizer with no voltage regulation), using a 5v source, a 3 ohm atomizer would dissipate about 8.3 watts of power. So, would using a 75% duty cycle dissipate 8.3*0.75=6.2 watts, 60% dissipate 8.3*0.6=5 watts, etc., etc.?

I'm probably a very long way away from a homebuilt variable power mod, but in the meantime I can always play around with a 556, some power transistors, and nichrome wire on my bench. Thanks for any input you may have, and thanks again for this extremely informative forum.

Thanks for any input you may have, and thanks again for this extremely informative forum.

About a year ago I quit smoking cold turkey after having a first rib resectomy because of Paget-Schroetter disease. Fast forward about 7 months and I was back to smoking again when I was working a few months overnight. If I had done my research on this forum beforehand I probably would have avoided buying a ridiculously overpriced/underfeatured starter kit (I'll let you guess which one.

So, anywho... on to my current question.

Most mods and vv batteries I've seen use linear voltage regulation. Nothing wrong with that, as so many probably have proved. I like to tinker with circuits though, and was looking at using pulse-width modulation to control power delivered to the atmoizer ("wattage"... am I the only one who doesn't like that term, lol). Basically, switching full voltage to the atmomizer quickly (68 kHz is easily done with a 555 multivibrator), at a duty cycle from 100% down to however low still manages to vaporize the e liquid. At 100% duty cycle (basically equivalent to a switch between the battery and atomizer with no voltage regulation), using a 5v source, a 3 ohm atomizer would dissipate about 8.3 watts of power. So, would using a 75% duty cycle dissipate 8.3*0.75=6.2 watts, 60% dissipate 8.3*0.6=5 watts, etc., etc.?

I'm probably a very long way away from a homebuilt variable power mod, but in the meantime I can always play around with a 556, some power transistors, and nichrome wire on my bench.