I've read so many threads and posts, I've confused myself.

I'm gonna go through my rebuild process with as much detail as possible in the hope someone can tell me what I'm doing wrong.

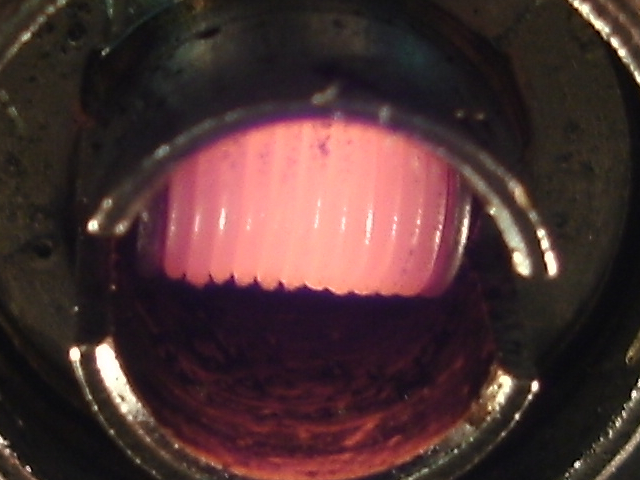

So.. 32g kanthal d wire, 2mm silica wick. This current build has 3 wraps, burns evenly when fired, tastes like crap, and stranger to me still reads 2.3ohms, how on a 3 wrap does it read at 2.3!?!

I see no hot spots, the wraps may as far as I can tell be slightly loose. The legs have been cut as close as possible to the post, there's no way they're making contact with anything they shouldn't.

Please for the love of god let there be something in this post that someone sees as so obvious that I must just be stupid

If you can help me, please do, I'll buy you a beer or 10!. Thank you.

Sent from my GT-I9505 using Tapatalk

I'm gonna go through my rebuild process with as much detail as possible in the hope someone can tell me what I'm doing wrong.

So.. 32g kanthal d wire, 2mm silica wick. This current build has 3 wraps, burns evenly when fired, tastes like crap, and stranger to me still reads 2.3ohms, how on a 3 wrap does it read at 2.3!?!

I see no hot spots, the wraps may as far as I can tell be slightly loose. The legs have been cut as close as possible to the post, there's no way they're making contact with anything they shouldn't.

Please for the love of god let there be something in this post that someone sees as so obvious that I must just be stupid

If you can help me, please do, I'll buy you a beer or 10!. Thank you.

Sent from my GT-I9505 using Tapatalk