One of the nice features of the Vivi Nova is the replaceable atty head. While the stock head design is good (sic) for the intended production performance, it is somewhat lacking with respect to wicking. (IMO) A number of rebuild tutorials here in this

thread and elsewhere have focused on changing the wick material (cotton, bamboo, SS mesh, etc) or altering the head design (bigger slots, boring out a hole, etc), or coil designs or a combinations of these more or less with the original design intent.

I have tried a number of these and while some were really great, each had trade offs. The following approach, a bit different that previous approaches has provided me the best performance yet with a Vivi and I and I wanted to share with you.

The core of the design concept is not new, but I want to share what I did for those that may wish to try it on a Vivi.

The basic concept was to replicate a carto within the Vivi head. My objective was to maximize wick on coil, maintain proper airflow and allow for rebuild using "safer than silica" material.

Here goes:

Using the "machine screw method", you form an appropriate coil for target ohm resistance. Here I used a 2mm screw. I double twisted the 32g kanthal leg that goes

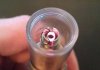

through the center of the grommet. I left the top leg as a single wire. I placed the coil with the screw still in the coil into the head and secured the bottom leg. I brought the top leg through the slot and wrapped it clockwise securing it through the bored out opening and then around the top lip of the head. (This was a head that was previously bored out for a cheesecloth coil) After centering the coil, I removed the screw and achieved a perfect glow. Resistance was higher than I wanted at 3.1 ohms, but the coil was perfect so I proceeded with the build.

I then chose to use cheesecloth as the wick material, but you can most likely use Bamboo or cotton yarn as well. I did try cotton batten and will share some thoughts on that shortly.

To maintain coil integrity during the wick placing process, I insulated the coil with a plastic straw, cut down the middle to accommodate the coil size the and the top wire. I placed ten strand twists of cheescloth at a time on both sides of the coil through the slot and incrementally built up wick around the coil.

I alternated placing the twisted cheesecloth on each side of the coil to have it overlap in the slot. The plastic straw worked great to keep the coil shape. Note here that you have a very clear channel down to the air inlet of the base.

After placing all the cheesecloth twists, I gently removed the straw to see very nice coil coverage and a nice wide opening to the air inlet.

I placed a few more cheesecloth twists to cover the expose coils., then trimmed the wick legs and placed the head in the Vivi tank and primed it with juice.

The result were great. Compared to all other vivi set ups, this has produced the best overall vape so far.

After 5mls, this set up is still going strong. No decrease in airflow, no flooding, no funky taste...etc. The cottony flavor has diminished as well.

I still need to see how long this wick will last and how easy a change of wick material will be to really feel compelled here, but so far really outstanding.

--------------------------

A couple of additional thoughts...On my first try, I used a 1.5 mm coil and cotton batten. The vapor production was incredible. However, the wick failed, because the batton is so absorbent it expanded into the coil, became too wet and air flow was reduced. When I disassemble, it was a PITA to remove the batten. On this try, I increased the coil to 2mm and used cheesecloth to solve for both issues. Given performance so far, my next try (if/when this gives out) will be to use cheesecloth and a 1.5mm coil and/or perhaps incorporate some layers of batten. I may also revisit the top leg with a double twist down the center or perhaps some silver NR wire, but this really is not an issue so far.

So the short version here is:

1) Use the inner channel of the coil as the pathway for air flow.

2) Maximize wick on coil by using the outside of the coil for greater wick to coil surface area.

3) Use stranded material to facilitate removal during a wick change out.

4) Minimize the vapor chamber as much as possible.

Now back to my Grand Marnier...enjoy.

Just when ya think this tread has expored all the options, you think out of the box and come up with this. The pic's are great and help a lot to see what/how ya done it.

Just when ya think this tread has expored all the options, you think out of the box and come up with this. The pic's are great and help a lot to see what/how ya done it.