Ok so ive been using the same coil that i made about a couple weeks ago and its starting to get near needing replacement but ive tried to hook the NR wire up to my coil i made and i cant get the two to stay together for the life of me. Ive tried twisting multiple ways together and either they fall off or they are too big and touch the outside of my vivi nova head and short. I dont have any lead free solder and id like to avoid it. So if anyone has any ideas on how to get the wires to stay together would be appreciated!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Connecting resistance to NR

- Thread starter Thomas Simms

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

Watch one of the reviews of something like the Odysseus that Scott does on Youtube, it's a simple twist to make then stay together.

I've been making a few rebuildables at home using sterling silver wires (16ga) as lugs/posts for pos and negative. I just use a bit of slack nichrome wrapped around them 2 or 3 times.

Here is a place where it shows how to connect your resistance wire and no resistance wire. its about 10 pictures down

http://www.e-cigarette-forum.com/forum/atomizer-mods/294873-ce3xl-phoenix-tank-rebuild-how.html

http://www.e-cigarette-forum.com/forum/atomizer-mods/294873-ce3xl-phoenix-tank-rebuild-how.html

For me, the key to getting them to stay together is to angle the two wires out at right angles to the twisted portion as I twist them. That way, they make a good, tight twist, and can be clipped to about 1/8 inch afterward.

I tend to make the twisted parts stick up or down, and slightly inward, to keep them away from the sides of the head. Electrical current will bypass all but the initial joint of the twisted portion, as long as you don't short it to anything else, so no worries about it not contacting the wick and getting too hot.

ETA -

I should add that I now prefer to double the resistance wire legs by making them longer, and folding the ends back. I then twist them somewhat tightly, making sure to pick the last 1/16 inch or so of the wire on each end of the wire out at a right angle, and wrap that tightly around in order to form a loop that keeps it from unwinding.

I do that before winding it around the wick, so that last bit is important to keep the twisted legs intact while winding the coil. This uses more resistance wire, but it's a bit easier for me.

I tend to make the twisted parts stick up or down, and slightly inward, to keep them away from the sides of the head. Electrical current will bypass all but the initial joint of the twisted portion, as long as you don't short it to anything else, so no worries about it not contacting the wick and getting too hot.

ETA -

I should add that I now prefer to double the resistance wire legs by making them longer, and folding the ends back. I then twist them somewhat tightly, making sure to pick the last 1/16 inch or so of the wire on each end of the wire out at a right angle, and wrap that tightly around in order to form a loop that keeps it from unwinding.

I do that before winding it around the wick, so that last bit is important to keep the twisted legs intact while winding the coil. This uses more resistance wire, but it's a bit easier for me.

Last edited:

Here is Scotts Ody review. Notice how after he twists them together he wraps the twist with the NR wire. I think if you add this step you'll be fine. I make my twists a little on the long side, it makes it easier to do, then trim the twist before wrapping with the NR.

REVIEW OF THE ODYSSEUS REPAIRABLE ATOMISER - YouTube

REVIEW OF THE ODYSSEUS REPAIRABLE ATOMISER - YouTube

Also,if you use tweezers to twist them,its way easier and tighter...

My advice is to use needle from siring green one (don't now exact AWG number).

Cut small peaces like 2-2.5mm.

Use this like crimping, kantal/nichrome into one side, nr wire other side and crimp it all together with pliers.

This way you must have all that coil thing

Next is tide coil around the wick with help of needle and happy vaping

Cut small peaces like 2-2.5mm.

Use this like crimping, kantal/nichrome into one side, nr wire other side and crimp it all together with pliers.

This way you must have all that coil thing

Next is tide coil around the wick with help of needle and happy vaping

Thanks everyone for the great techniques they have been extremely helpful! Ever since i started rewicking my only hardware has been my vivi nova. Before rewicking, it was stashed in the junk drawer due to always burning. Now i have a new favorite!

You could set up an oxygen free carbon powder pot like they use for welding thermocouple wires of different alloys.

Sounds like a lot of trouble but they can be handy. Of course if you put it away and can't find it, it don't work.

1.5 inch pipe cap, variac, and an ounce of carbon powder, and welders googles. You can even shave the center electrode in carbon zinc D-cells to get the carbon.

Connect one lead from the variac to the pipe cap (bolt). Fold the two wires at the point you want to join, connect the other variac lead (alligator clip) to the end of both wires (temporarily twisted together), dip and weld in a circular path keeping the joint red and just out of the air. Couple of seconds per joint. Variac has to be set by trial and error for the gage wires being welded. Easily welds fine wires that can't be soldered. It blends the metals into a single alloy at the weld.

I looked for a link but couldn't find anything. I know it works, learned it in the 70's from a guy that did it in the 50's (probably in the 40's, but just being kind )

)

Sounds like a lot of trouble but they can be handy. Of course if you put it away and can't find it, it don't work.

1.5 inch pipe cap, variac, and an ounce of carbon powder, and welders googles. You can even shave the center electrode in carbon zinc D-cells to get the carbon.

Connect one lead from the variac to the pipe cap (bolt). Fold the two wires at the point you want to join, connect the other variac lead (alligator clip) to the end of both wires (temporarily twisted together), dip and weld in a circular path keeping the joint red and just out of the air. Couple of seconds per joint. Variac has to be set by trial and error for the gage wires being welded. Easily welds fine wires that can't be soldered. It blends the metals into a single alloy at the weld.

I looked for a link but couldn't find anything. I know it works, learned it in the 70's from a guy that did it in the 50's (probably in the 40's, but just being kind

Last edited:

You could set up an oxygen free carbon powder pot like they use for welding thermocouple wires of different alloys.

Sounds like a lot of trouble but they can be handy. Of course if you put it away and can't find it, it don't work.

1.5 inch pipe cap, variac, and an ounce of carbon powder, and welders googles. You can even shave the center electrode in carbon zinc D-cells to get the carbon.

Connect one lead from the variac to the pipe cap (bolt). Fold the two wires at the point you want to join, connect the other variac lead (alligator clip) to the end of both wires (temporarily twisted together), dip and weld in a circular path keeping the joint red and just out of the air. Couple of seconds per joint. Variac has to be set by trial and error for the gage wires being welded. Easily welds fine wires that can't be soldered. It blends the metals into a single alloy at the weld.

I looked for a link but couldn't find anything. I know it works, learned it in the 70's from a guy that did it in the 50's (probably in the 40's, but just being kind)

Wish you did have that link. I'm having a hard time visualizing this. I may go looking for it.

I can't find a link and I think most places that work with thermocouples use a computerized spot welder now.

Maybe a little better explanation would work (I'll use a dual alloy thermocouple as an example).

The Carbon pot:

We used a 1.5 inch threaded pipe cap, just because

Drilled and tapped a hole in the bottom to attach to a piece of plywood and another hole in the side to attach a binding post. We had a 2 pound tin can of carbon powder that must have been surplus from Edison's lab. Fill the pipe cap with the carbon powder.

At this point you have a pipe cap bolted to a piece of plywood with a terminal to attach something electrical to it.

Needless to say it looks ominous and home made

To weld a thermocouple, make a twist at the end of the two different alloy wires so they will remain close together while welding. Use an insulated alligator clip to attach another lead to both wires. The purpose is to conduct current through both leads at the same time in parallel from where the clip is attached to the twisted end. When dipped into the carbon powder they will conduct, heat up and resistance weld at the point the current goes from the wire to the hot carbon.

We used a variac set to about 20 volts (just enough voltage for an arc in the carbon powder) for 28ga wires, but it would vary a little from alloy to alloy.

Welding: Wear goggles (not googles)

dip the twisted end (a single twist) of the thermocouple into the carbon powder, below the surface and keep it moving to keep fresh carbon next to the wires as they heat up. The glowing carbon will combine with any Oxygen in the air that is near the wires. Don't bump the sides of the pipe cap or you just welded the wires to the cap.

AC Current Flow: From one lead of the variac to the alligator clip, down the thermocouple wires to the end dipped in the carbon powder, through the carbon powder to the pipe cap, and back to the variac. Typically only tool about 3 seconds to make a nice little welded blob.

For a small ga wire to a larger gage wire, like a 28 ga Constantine wire to a 20 ga copper wire, make a single wrap of the smaller wire near the end of the larger wire, with a small amount of the larger wire projecting out. The weld will start heating the larger wire first then consume the wrap.

The one I made for home use had the pipe cap bolted inside a metal 3X5 card holder, with a flip top lid. I could store the leads and clips in the box. Just can't find it now. If I run across it, I'll post a pic.

Maybe a little better explanation would work (I'll use a dual alloy thermocouple as an example).

The Carbon pot:

We used a 1.5 inch threaded pipe cap, just because

Drilled and tapped a hole in the bottom to attach to a piece of plywood and another hole in the side to attach a binding post. We had a 2 pound tin can of carbon powder that must have been surplus from Edison's lab. Fill the pipe cap with the carbon powder.

At this point you have a pipe cap bolted to a piece of plywood with a terminal to attach something electrical to it.

Needless to say it looks ominous and home made

To weld a thermocouple, make a twist at the end of the two different alloy wires so they will remain close together while welding. Use an insulated alligator clip to attach another lead to both wires. The purpose is to conduct current through both leads at the same time in parallel from where the clip is attached to the twisted end. When dipped into the carbon powder they will conduct, heat up and resistance weld at the point the current goes from the wire to the hot carbon.

We used a variac set to about 20 volts (just enough voltage for an arc in the carbon powder) for 28ga wires, but it would vary a little from alloy to alloy.

Welding: Wear goggles (not googles)

dip the twisted end (a single twist) of the thermocouple into the carbon powder, below the surface and keep it moving to keep fresh carbon next to the wires as they heat up. The glowing carbon will combine with any Oxygen in the air that is near the wires. Don't bump the sides of the pipe cap or you just welded the wires to the cap.

AC Current Flow: From one lead of the variac to the alligator clip, down the thermocouple wires to the end dipped in the carbon powder, through the carbon powder to the pipe cap, and back to the variac. Typically only tool about 3 seconds to make a nice little welded blob.

For a small ga wire to a larger gage wire, like a 28 ga Constantine wire to a 20 ga copper wire, make a single wrap of the smaller wire near the end of the larger wire, with a small amount of the larger wire projecting out. The weld will start heating the larger wire first then consume the wrap.

The one I made for home use had the pipe cap bolted inside a metal 3X5 card holder, with a flip top lid. I could store the leads and clips in the box. Just can't find it now. If I run across it, I'll post a pic.

Last edited:

For those who are still having difficulty & don't want to be going to the nerd extremes to join a little wire there are simpler options. I soldered (soddered for US readers) them after twisting until I realised that the join was more than strong enough without soldering.

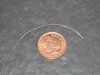

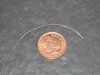

However as I said......other simple options. To secure your join try a 1.5mm (or 1mm) brass crimp tube over your join. You can buy them plated....slver, gold, or I have them platinum plated. You can always trim any excess from the tube after crimping or leave it as it is. In the pic below I twisted the join on the left & used a crimp on the join on the right. (the non resistive wire is in the middle as I only done the pic to show someone how its done)

Brass Crimp Tubes | eBay

However as I said......other simple options. To secure your join try a 1.5mm (or 1mm) brass crimp tube over your join. You can buy them plated....slver, gold, or I have them platinum plated. You can always trim any excess from the tube after crimping or leave it as it is. In the pic below I twisted the join on the left & used a crimp on the join on the right. (the non resistive wire is in the middle as I only done the pic to show someone how its done)

Brass Crimp Tubes | eBay

Last edited:

I can't find a link and I think most places that work with thermocouples use a computerized spot welder now.

Maybe a little better explanation would work (I'll use a dual alloy thermocouple as an example).

The Carbon pot:

We used a 1.5 inch threaded pipe cap, just because

Drilled and tapped a hole in the bottom to attach to a piece of plywood and another hole in the side to attach a binding post. We had a 2 pound tin can of carbon powder that must have been surplus from Edison's lab. Fill the pipe cap with the carbon powder.

At this point you have a pipe cap bolted to a piece of plywood with a terminal to attach something electrical to it.

Needless to say it looks ominous and home made

To weld a thermocouple, make a twist at the end of the two different alloy wires so they will remain close together while welding. Use an insulated alligator clip to attach another lead to both wires. The purpose is to conduct current through both leads at the same time in parallel from where the clip is attached to the twisted end. When dipped into the carbon powder they will conduct, heat up and resistance weld at the point the current goes from the wire to the hot carbon.

We used a variac set to about 20 volts (just enough voltage for an arc in the carbon powder) for 28ga wires, but it would vary a little from alloy to alloy.

Welding: Wear goggles (not googles)

dip the twisted end (a single twist) of the thermocouple into the carbon powder, below the surface and keep it moving to keep fresh carbon next to the wires as they heat up. The glowing carbon will combine with any Oxygen in the air that is near the wires. Don't bump the sides of the pipe cap or you just welded the wires to the cap.

AC Current Flow: From one lead of the variac to the alligator clip, down the thermocouple wires to the end dipped in the carbon powder, through the carbon powder to the pipe cap, and back to the variac. Typically only tool about 3 seconds to make a nice little welded blob.

For a small ga wire to a larger gage wire, like a 28 ga Constantine wire to a 20 ga copper wire, make a single wrap of the smaller wire near the end of the larger wire, with a small amount of the larger wire projecting out. The weld will start heating the larger wire first then consume the wrap.

The one I made for home use had the pipe cap bolted inside a metal 3X5 card holder, with a flip top lid. I could store the leads and clips in the box. Just can't find it now. If I run across it, I'll post a pic.

Thanks, I think what threw me was the circular motion part. I couldn't figure out what was moving in a circular motion. I actually have a really old General Radio Company variac laying around. It weighs a ton and looks like it came out of a Frankenstein movie.

I actually have a really old General Radio Company variac laying around. It weighs a ton and looks like it came out of a Frankenstein movie.

Yup, that's what we used

Yup, that's what we used

One question. We're just talking about a 1 1/2" galvanized pipe cap with a bolt in the side right?

One question. We're just talking about a 1 1/2" galvanized pipe cap with a bolt in the side right?

In the lab, we had a big variac to run equipment through the max and min input voltage to check performance. I think it was rated at a kilowatt. Way more bigger than necessary. A 1.5 inch pipe cap as the ground conductor for the carbon powder 'electrode' could be just about any conductive 'cup'. 1.5 inch was big enough to not have to worry about bumping the sides and shorting out the wires, which would then melt quickly

At home I have a 200 watt autotransformer (unknown brand) that I used. just about anything that can be adjusted will probably work. 20 to 30 volts or so should sustain an arc in the carbon. We welded TCs from 28 to 18 ga. and it worked great.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 34

- Views

- 3K

- Replies

- 23

- Views

- 5K

- Replies

- 5

- Views

- 812

- Locked

- Replies

- 7

- Views

- 880

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)