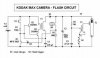

I have noticed that different people are working with different circuits. I have found the following schematics, and it seems like the fuji has a charge button that you need to hold, while the Kodak has a one touch charge button that you can release, and the charging continues.

There also seems to be two schools of though on how to get the correct voltage. The fuji boards can "pulse" to get the desired voltage, checked on a meter. The Kodak models, which I'm currently using, needs to be regulated. Some kodaks use a Zener Diode, and I'm working on varying the value of this, to have the voltage regulated at a predetermined value. A led, with proper resistors, can serve as a indicator that the cap is charged, and ready to weld.

For simplicity, and not needing a meter, I'm currently working on the Kodak Zener boards. I'd like to give some of these to friends, and can't afford to give away meters....

More info to follow...

There also seems to be two schools of though on how to get the correct voltage. The fuji boards can "pulse" to get the desired voltage, checked on a meter. The Kodak models, which I'm currently using, needs to be regulated. Some kodaks use a Zener Diode, and I'm working on varying the value of this, to have the voltage regulated at a predetermined value. A led, with proper resistors, can serve as a indicator that the cap is charged, and ready to weld.

For simplicity, and not needing a meter, I'm currently working on the Kodak Zener boards. I'd like to give some of these to friends, and can't afford to give away meters....

More info to follow...