We all know how distillation works. Control the boiling temp of a liquid and everything with a boiling point below that temp boils off. Great for moonshine, not so for atomizers. I clearly notice the difference in the juice as I go through a tank. I did consider that if the tank was truly isolated from the coils, it shouldn't be happening. But it is so, what's the solution to this issue? PS why can't I create a tag with the word distillation?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Distillation Problem

- Thread starter Gentle Smoke

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

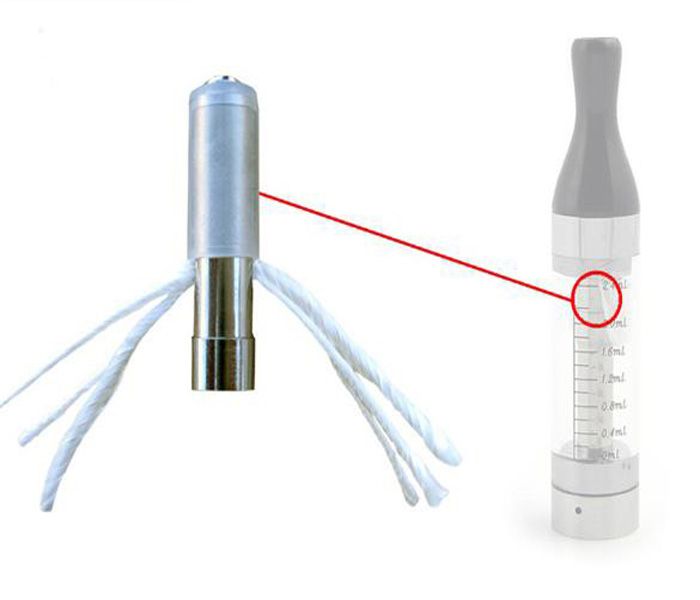

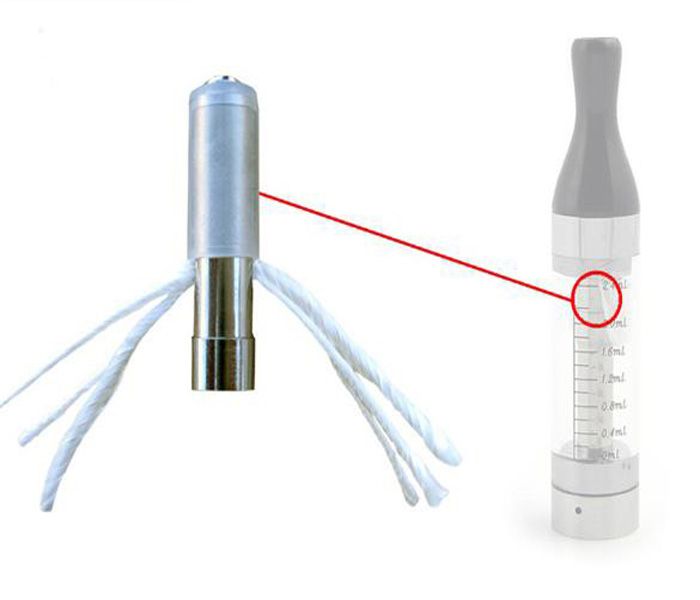

Your post reminds me of years ago when I used those awful Kanger long-wick coil heads.

The sediment would descend down the strands and pollute the clean liquid in the tank.

You should share a picture of your setup so we have some idea what you're dealing with.

Distillation isn't a really word that is associated with vaping since the e-juice itself doesn't actually reach its boiling point. Rather, the water contained in the e-liquid flash-boils which spits out droplets of liquid e-juice. What's left behind is some sediment from the flavoring, and scorched wicking if your setup runs too hot.

The sediment would descend down the strands and pollute the clean liquid in the tank.

You should share a picture of your setup so we have some idea what you're dealing with.

Distillation isn't a really word that is associated with vaping since the e-juice itself doesn't actually reach its boiling point. Rather, the water contained in the e-liquid flash-boils which spits out droplets of liquid e-juice. What's left behind is some sediment from the flavoring, and scorched wicking if your setup runs too hot.

Hello GO Don't have a picture but, I'm running a Dead Rabbit RTA with rayon wicks. According to an article I read here, thinning the tails eliminates back draw from the coils and having perfectly even length tails promotes bilateral draw. The last one is quite difficult but, I'm trying. Also, please see my comment to your post on boiling point calculator.

PS: My prior atomizer was a Vaporesso Cascade Baby with ceramic coils. I felt the same ordered loss with that atomizer also.

According to an article I read here, thinning the tails eliminates back draw from the coils and having perfectly even length tails promotes bilateral draw.

Do you mind sharing this link?

What is it are you trying to achieve?

The boiling point of ethanol is 75C, water 100C, PG 188C, VG 290C, but this stuff is thoroughly emulsified and quite possibly in solution since I've never seen it separate. That's pretty terrifying that you would see ingredients "distilling" away in that order. How are you sure that's actually what's happening?...the distillation problem. As I vape (TC Mode) my etoh - h20 - pg - vg mix, clearly they are disappearing in order of boiling point. So saying that I'm always at 100c isn't correct. Yes, when there's water still in the mix, I sense a lower temperature. However, there is a combined solution boiling point that I think I should hit to get a uniform vaporization (although I take it that you would argue against this). And, ultimately why I want to know the boiling point is to make a judgement as to whether my TCR is set correctly.

My understanding is that "Vegetable Glycerin and Propylene Glycol are hygroscopic. That means they suck up the water in the air and absorb it" so it should never run out of water.

The Dead Rabbit RTA looks very similar in design to the Zeus X RTA I use.

You might consider a rdta, coils aren't in contact with the tank juice. If you wick often you shouldn't notice any difference in the taste.

Hello Punk The article I referred to is: Rayon Wick - Better Flow, Flavor, Longevity, and Nic Hit!! - Pt.2. Its first post advises as to rayon wicking. What I trying to achieve is to vape consistently as to flavor / low temp experience. And GO, I sense this by taste and temperature. You can't miss that the small quatity of alcohol is boiling off first, probably all gone by 1/4 tank. As to water, I'd say it hangs around to 80 plus percent of the tank. When getting towards the end of the tank, I find that I'm raising the temp to get adequate vapor.

I'd definitely suggest that you take the ethanol out of your mix.

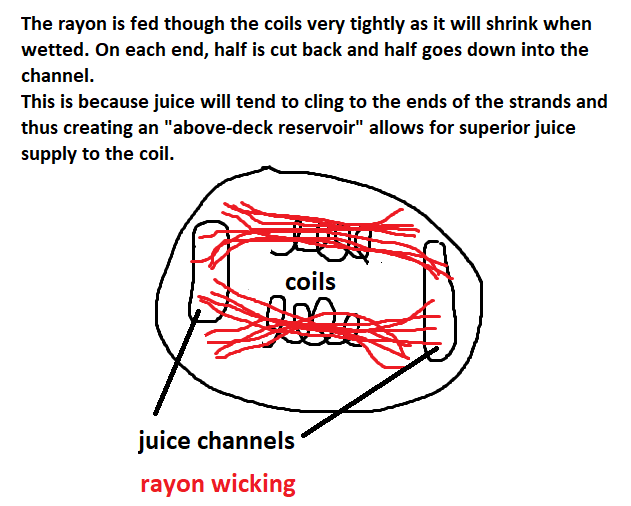

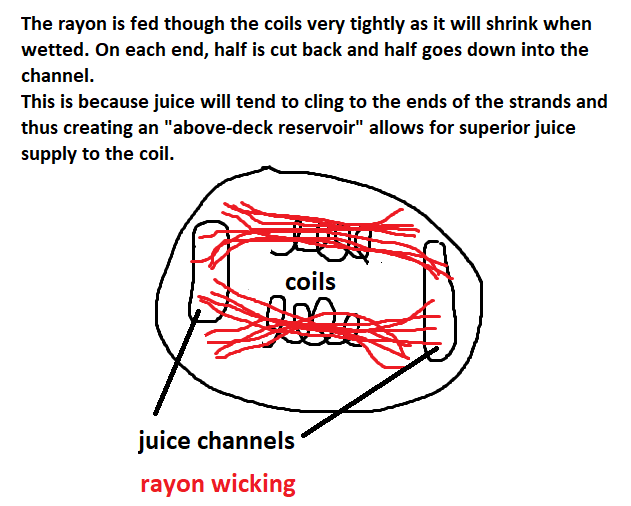

And I made a drawing on how to use rayon, based on this howto video.

Disclaimer: I haven't got any first-hand experience with rayon.

And I made a drawing on how to use rayon, based on this howto video.

Disclaimer: I haven't got any first-hand experience with rayon.

Anyone with experience vaping clearo's might understand that what we're dealing with more resembles kitchen science and so reduction. Back in the day with the quality of drop-in's often shorting turn-to-turn, irregularly heating or actually arcing we "darkened" a heck of a lot of juice. And given that water actually only constitutes probably <.5% of most recipes, it's pretty easy to do.

As the experiment has been done a gazillion times by so many of us, it's pretty common knowledge when your tank starts to foul like this…it don't vape. Depletion of the water component definitely occurs. Freshen up the tank a bit and you've got your vape back.

I never understood "thinning" (to account for gravity?). How do you get more liquid to go through less hose (when it's already wet)? Too much for my little head.

RxW (Nextel braid wicking) are incredibly tightly wound ceramic fibers. Not only does it flow like mad and is utterly flavor neutral its small (micron size) capillaries retain fluid very well. If you want it dry you're going to have to vape it dry. The advantage is that the juice inside doesn't tend to oxidize. The fabulous flavor you enjoy is always nearby. Add a drop of VG (water) to prime, wet it or drip it and you're back in business inside of one or two pulls…flavor and volume as you meant it to be...overnight or even days later. Now tell me you can do that with any other kind of wicking.

There's a lot to be said for squonkers and bottom-fed RDA's for a clean tasting vape. Doesn't surprise me why those flavor lovers were the leading exponents of Nextel early on in vaping.

Good luck.

As the experiment has been done a gazillion times by so many of us, it's pretty common knowledge when your tank starts to foul like this…it don't vape. Depletion of the water component definitely occurs. Freshen up the tank a bit and you've got your vape back.

I never understood "thinning" (to account for gravity?). How do you get more liquid to go through less hose (when it's already wet)? Too much for my little head.

RxW (Nextel braid wicking) are incredibly tightly wound ceramic fibers. Not only does it flow like mad and is utterly flavor neutral its small (micron size) capillaries retain fluid very well. If you want it dry you're going to have to vape it dry. The advantage is that the juice inside doesn't tend to oxidize. The fabulous flavor you enjoy is always nearby. Add a drop of VG (water) to prime, wet it or drip it and you're back in business inside of one or two pulls…flavor and volume as you meant it to be...overnight or even days later. Now tell me you can do that with any other kind of wicking.

There's a lot to be said for squonkers and bottom-fed RDA's for a clean tasting vape. Doesn't surprise me why those flavor lovers were the leading exponents of Nextel early on in vaping.

Good luck.

Last edited:

You mean raking out the cotton to thin the ends? The only time it makes sense to me is when the volume of material would cause a constriction. The prime example would be an RTA where the cotton needs to descend into and fill the juice channels but still be loosely packed enough to wick properly. If it's densely packed into those channel then juice won't rise easily to the coils.I never understood "thinning" (to account for gravity?). How do you get more liquid to go through less hose (when it's already wet)? Too much for my little head.

Geekvape Framed Staple Contact 0.12Ω Dual Coil Build Side View

Geekvape F202 Framed Staple Fused Clapton Coil 4-wrap 0.25Ω x2 on Zeus X

So it wouldn't make much sense to rake the cotton in say, an RDA. Also rayon seems to work a bit differently from cotton.

Last edited:

You cant seperate water, PG and VG by distillation and I find it hard to believe that PG gets "vaped away" and the VG stays in the tank. How is that supposed to happen?

Did some tests at work on vapor composition vs liquid composition and its the same.

Did some tests at work on vapor composition vs liquid composition and its the same.

That’s what I was thinking. It’s like presuming that since alcohol weighs less than soda, if you make a Jack and Come you’d drink off most of the Jack before getting to the soda.You cant seperate water, PG and VG by distillation and I find it hard to believe that PG gets "vaped away" and the VG stays in the tank. How is that supposed to happen?

Did some tests at work on vapor composition vs liquid composition and its the same.

The science is beyond me, I admit, but mixed together surely there is some bonding of atoms or something like that.

It’s one thing to say each ingredient has its own boing point. Boil them each separately and you’ll see those results. But I’d expect that mixed, you would see that their boiling points would be an average of their individual temperatures.

What sort of coils are you using? Single or dual? What's the total resistance? What material are they built from?low temp experience

my TCR

What kind of mod?

What approximate wattage range are you seeing?

May I refer you all to a nice heated argument from 2014 in this forum? How it works: coils, temperature, juice, etc.

And Mac Tech, I believe you have the solution. I've started to run my RTA at low volume and am adding juice when It approaches exposing the ports. Definitely more flavorful and consistent.

You cant seperate water, PG and VG by distillation and I find it hard to believe that PG gets "vaped away" and the VG stays in the tank. How is that supposed to happen?

Did some tests at work on vapor composition vs liquid composition and its the same.

Water expands of a ratio of approx 1600:1 @ 100C when vaporized. A boiling point is a constant. It's a volatile process which aerosolizes the solution otherwise, i.e. PG/VG, into the fine mist we see. That is my understanding. Determining just how much of the VG or PG we might be vaporizing with the breath of hardware and chem in use would seem to me to be highly problematical.

Good luck.

May I refer you all to a nice heated argument from 2014 in this forum? How it works: coils, temperature, juice, etc.

Thanks for the validation here.

To which I'll disagree somewhat with the common consensus that it's dry heating that causes accretion. It certainly can exacerbate it but it does so by baking it in. What got the juice that "sticky" in the first place? Well…just as in the kitchen, heat. Heat short of or inadequate to achieve uniform vaporization. And once such deposition begins high dry heat will bake it in. Just like in the kitchen or on the grill.

And Mac Tech, I believe you have the solution. I've started to run my RTA at low volume and am adding juice when It approaches exposing the ports. Definitely more flavorful and consistent.

Yes, I've been running half tank fills for many years to avoid undue concentration and keep flavor/output levels high. Juice is good but…

I encourage peep's I teach to rebuild and testers in my baseline DIY distribution to use VG. My recipes are 10-20% over the flavor target to allow for generous use of VG (~.5% water) to freshen tanks or to prime dripping (1 drop to 6-7 juice). This keeps output robust and the installation clean by helping to promote optimal vaporization. It's under-vaporization that is our nemesis. If the recipe is a bit on the rich side this facilitates this method.

Because the .5% of water in raw VG is diluted by ingredients somewhat, straight VG can give it a boost.

Good luck.

Last edited:

@MacTechVpr - Love your posts, always lots of info to consume and chew on. But question: It is a know fact that sighted tests can lead to biased results. Have you blindly tested your theories?

- Status

- Not open for further replies.

Similar threads

- Locked

- Replies

- 2

- Views

- 486

- Replies

- 11

- Views

- 1K

- Replies

- 5

- Views

- 857

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)