I just got privileges to create a new thread, and have also done a bit more investigation to determine some preliminary feasibility. So, here goes a new thread about creating a high density atomizer that is viable for a puppet stage smoke machine or perhaps a pipe.

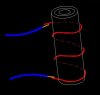

Attached is an image of what I am thinking about. A simple loop of nichrome wire that is wrapped around a loop of wicking material. I think the wick can be a flameproof fiberglass ribbon, like that used for seals on a wood stove.

The idea is that there is a large amount of wick available to each portion of wire, as opposed to the standard tight coil of nichrome. The standard tight coil will tend to use up all the available juice when it is used for a longer than normal time period (i.e. over 5 seconds).

I've attached two images. One with a short, fat coil, perhaps best for a pipe. In this case, the nichrome may be best located on the inside of the wick, and actually threaded through the wick to facilitate drawing the smoke through the center. The 2nd version has the nichrome wrapped around the wick.

I don't have any nichrome wire to test these ideas out, but will probably order some soon. Any one else want to try it out?

Joe Dunfee

Attached is an image of what I am thinking about. A simple loop of nichrome wire that is wrapped around a loop of wicking material. I think the wick can be a flameproof fiberglass ribbon, like that used for seals on a wood stove.

The idea is that there is a large amount of wick available to each portion of wire, as opposed to the standard tight coil of nichrome. The standard tight coil will tend to use up all the available juice when it is used for a longer than normal time period (i.e. over 5 seconds).

I've attached two images. One with a short, fat coil, perhaps best for a pipe. In this case, the nichrome may be best located on the inside of the wick, and actually threaded through the wick to facilitate drawing the smoke through the center. The 2nd version has the nichrome wrapped around the wick.

I don't have any nichrome wire to test these ideas out, but will probably order some soon. Any one else want to try it out?

Joe Dunfee