Has anyone tried it? I imagine it would work best with ribbon wire. What I'm getting at is something like this:

The bends in the wire create resistance, much like a typical wound coil. However it occurs to me that if someone could pull this off in an rda, it could be a big flavor and vapor kicker due to a flatter and increased surface area.

So, zig zag coils, feasible, and has anyone tried it?

The bends in the wire create resistance, much like a typical wound coil. However it occurs to me that if someone could pull this off in an rda, it could be a big flavor and vapor kicker due to a flatter and increased surface area.

So, zig zag coils, feasible, and has anyone tried it?

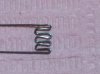

) in the picture I made with a pair of needle-nose pliers and a smooth flat tip pliers.

) in the picture I made with a pair of needle-nose pliers and a smooth flat tip pliers.