Hello there. Here is the story. I've been asked by a number of people to make them an e-pipe. I had a thread over in the mod section but got a hand slap for pre-saleing. I was in the wrong, so now I'm here, where I should be. I'm going to proto-type a few pipes, come up with a model I like and can build. The first four pipes will be for myself. This may turn into a full time business or just a hobby, time will tell. Whatever happens you will see it to the end.

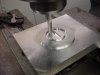

I started by designing a touch circuit and a battery holder. The battery holder is 1" in dia so it will fit into the bowl. Tomorrow I'll show the PCB and the casted battery holder. I already have the mold made for the battery holder. Enjoy

I started by designing a touch circuit and a battery holder. The battery holder is 1" in dia so it will fit into the bowl. Tomorrow I'll show the PCB and the casted battery holder. I already have the mold made for the battery holder. Enjoy