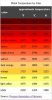

Or when manufacturing it.. The health hazard rating is a 1 ... That's good on the list of health problems

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pyrex Tube/Inner Coil/SS Mesh Genesis Mod

- Thread starter Big Screen D

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

We really need someone to point a heat temp gun on a glowing coil and see what temps we are dealing with...I'm sure it's posted somewhere but not interested In looking around the forums right now lol

I believe this was done back in Scubabatdan's original thread - I don't recall the exact temparature, but I seem to recall it being over 1200°F...

Ahh ok dsy makes sense so we are safe at 2k plus

I just worry about it becoming crumbly under the heat and giving off any particulates. I would want to test it thoroughly before attempting a working wick.

We are not saying anybody should use this. If we and others are interested in using it we can talk about it and it's potential for use. I know someone may look at this from the outside world, but almost everything except water has a health risk of 1 if not way higher of a health risk. For instance check this. http://www.essentialdepot.com/msds/msds%20glycerin%20kosher%20food%20grade.pdf

I just worry about it becoming crumbly under the heat and giving off any particulates. I would want to test it thoroughly before attempting a working wick.

Last edited:

After cleaning the bulk of the accumulated gunk off of the wick yesterday in a PGA bath, seems I had pronounced the patient healed a bit prematurely. While it looked clean, beauty was only skin deep. A close observation revealed that part of the wick was still not producing vapor as it should, and had been earlier. So what I determined is that the top half or so of the heated wick portion that should be producing was clogged below the surface.

Now having melted several tubes during dry fire testing, I have been working under the assumption that dry burning using Pyrex was out of the question. Turns out, that is not so. In a dimly lit room, I can see the coils glow through the thin layers of mesh. So I was able to fire in short low voltage burst firing just until the coils glow. 8-10 cycles of this, and I had a ash grey wick, that brushed up nice and clean, and is kicking but again.

Some great work running down some options for using FQ tubes guys. By this time next week, we should have a pretty good idea which tubes are the best choice for this method.

Another observation. I had mentioned that I cracked a couple of tubes by overdoing it during testing. Having almost did it again after cleaning this evening, I know now what happened. Running the wick dry=overheated tube=cracked tube when tilted to re-wet as the juice rushes into the hot wick and shocks the glass. With that in mind, always prime a dry wick before use.

One other thing regarding liquid entering the top of the tubes as I make them. Even a long shower under the faucet, and a PGA bath only allowed the equivalent of several drops inside the tube. This minor amount was quickly expelled through the tiny opening during dry burning with the tube angled down. I'd use caution completely sealing these tubes as I have concern should the glass or top seal fail, we'd have lift off! Strongly suggest using a needle to leave a not quite airtight passageway in the top seal. Just shape it so moisture runs off and not down inside the tube.

Now having melted several tubes during dry fire testing, I have been working under the assumption that dry burning using Pyrex was out of the question. Turns out, that is not so. In a dimly lit room, I can see the coils glow through the thin layers of mesh. So I was able to fire in short low voltage burst firing just until the coils glow. 8-10 cycles of this, and I had a ash grey wick, that brushed up nice and clean, and is kicking but again.

Some great work running down some options for using FQ tubes guys. By this time next week, we should have a pretty good idea which tubes are the best choice for this method.

Another observation. I had mentioned that I cracked a couple of tubes by overdoing it during testing. Having almost did it again after cleaning this evening, I know now what happened. Running the wick dry=overheated tube=cracked tube when tilted to re-wet as the juice rushes into the hot wick and shocks the glass. With that in mind, always prime a dry wick before use.

One other thing regarding liquid entering the top of the tubes as I make them. Even a long shower under the faucet, and a PGA bath only allowed the equivalent of several drops inside the tube. This minor amount was quickly expelled through the tiny opening during dry burning with the tube angled down. I'd use caution completely sealing these tubes as I have concern should the glass or top seal fail, we'd have lift off! Strongly suggest using a needle to leave a not quite airtight passageway in the top seal. Just shape it so moisture runs off and not down inside the tube.

Link to msds on the fireplace stuff..

Thanks dsy

http://www.imperialgroup.ca/userfiles/file/GA0188 Stove & FP Mortar.pdf

Thanks dsy

http://www.imperialgroup.ca/userfiles/file/GA0188 Stove & FP Mortar.pdf

Yea I am not planning on totally sealing, but leaving some area for pressure to expel..

Fireplace stuff sounds scary, but the mica and silica are encapsulated within the emulsion. More than likely would be safe as long as it's not crumbly. For added peace of mind, might be good to use a two part plug. HT cement topped with HT Silicone to insure isolation.

Or you could just melt Pyrex tubes We know that works!

We know that works!

Or you could just melt Pyrex tubes

The resistor coat is a great idea, I have seen resistors glow from overheating and the finish of the resistor remain almost enamel like. Just don't grind/scrape on it. Try injecting it in each end of the fq tube and then hardening it. I'll bet you could dip a completed coil with nr end leads in it and just wrap it with ss mesh and it would work. As far as friability asbestos isn't a huge danger as long as it isn't disturbed and this stuff is a heck of lot less dangerous than that. ( no I DID NOT suggest asbestos!).

I have been lurking and had to throw in my two cents worth.

Matt

Sent while sitting on my .... in my living room vaping away!

I have been lurking and had to throw in my two cents worth.

Matt

Sent while sitting on my .... in my living room vaping away!

Found the post in Dan's original thread on the temperature of a coil - http://www.e-cigarette-forum.com/forum/modding-forum/351986-pyrex-ss-hybrid-wick-36.html#post7877080. Cloudchaser had measured 1048°F after a 1 minute burn; keep in mind that this was wrapped around a ss wick - in a tube, I would think it could reach at least that temperature in a shorter amount of time.

The cement I recommended has a maximum servicing temp of 2600F that 1427C. Our use is well below that temp.

What about using a short piece of Pyrex (5mm) melted inside the FQ tube to plug it?

Goode that would probably work on the bottom, if the fq is big enough.. But we don't want to totally seal it...

Oh, I thought the goal is to seal it. I was thinking if you used a Pyrex plug in FQ on both ends, you could seal one end, let it cool, heat the whole tube while sealing the other end, to expand the air inside before getting the final seal, achieving a partial vacuum.

Hi there from Germany,

I've received some 1.5-1.8mm pyrex tubes and started to experiment with it. Since i want to use it with my GLV, i need a coil with both ends at the bottom. Making a double helix style coil seems to work quite well, the hardest part is to separate the two right at the bottom. These things are tiny and my phone can't focus on them, so no pics for now.

TAz

I've received some 1.5-1.8mm pyrex tubes and started to experiment with it. Since i want to use it with my GLV, i need a coil with both ends at the bottom. Making a double helix style coil seems to work quite well, the hardest part is to separate the two right at the bottom. These things are tiny and my phone can't focus on them, so no pics for now.

TAz

Lol taz, yes I use a magnifying glass when making mine.. If u have a genesis type atty we connect the negative to non resistant wire and run it up through the fill hole and connect it, that way we don't have to double it.. But if what you are doing works we will love to see pics..AZ was doing some of that I thought also..

checking in..hows it going with you guys on the modding of this wick??? Want pics..LOL and comments..

- Status

- Not open for further replies.

Similar threads

- Replies

- 48

- Views

- 9K

- Locked

- Replies

- 5

- Views

- 1K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)