Mac, I'm not getting the same success with SS wire. Am I correct in assuming it's due to a wholly different oxidising process? I'm finding SS and Nichrome acceptable in Clapton builds, but for plain wire, Kanthal is still my honey.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tensioned Micro Coils. The next step.

- Thread starter super_X_drifter

- Start date

- th_trl_thread_readers 0

- Status

- Not open for further replies.

Mac, I'm not getting the same success with SS wire. Am I correct in assuming it's due to a wholly different oxidising process? I'm finding SS and Nichrome acceptable in Clapton builds, but for plain wire, Kanthal is still my honey.

Find the same. SS is powerful but a lot warmer more diffuse production than strained Kanthal. If that's the goal that's great. If you want a center of density and diffusion you need precise control of the vaporization rate, the means to get to that. If it were as simple as just proper wicking and a resistance everyone would have it. But with open winds you have small variations in resistance that tend to make every wind we do differ slightly or more so.

How do you duplicate a vape experience if you can't precisely repeat it?

SS as you may know doesn't oxidize in the same way. Alumina is an insulator what allows close contact without driving res up. Pulse oxidation locks this into the relationship of turns in a contact coil. This allows a very uniform development of that insulation preserving some rigidity in the process when done right. That's what yields the service life and consistently high density potential. Kanthal is the only wire that exudes alumina. It was designed for this.

After sampling many rebuilt and factory coils nothing I've seen few come close to a Kanthal wind precisely dialed in to your own personal density and heat target. My main goal is to make sure vapers have a tool in hand to simply and neatly get it. Like I've said, a signpost at the crossroads they can always rely upon and get back to.

Me I've very happy living at that intersection most of the time.

Good luck.

Find the same. SS is powerful but a lot warmer more diffuse production than strained Kanthal. If that's the goal that's great. If you want a center of density and diffusion you need precise control of the vaporization rate, the means to get to that. If it were as simple as just proper wicking and a resistance everyone would have it. But with open winds you have small variations in resistance that tend to make every wind we do differ slightly or more so.

How do you duplicate a vape experience if you can't precisely repeat it?

SS as you may know doesn't oxidize in the same way. Alumina is an insulator what allows close contact without driving res up. Pulse oxidation locks this into the relationship of turns in a contact coil. This allows a very uniform development of that insulation preserving some rigidity in the process when done right. That's what yields the service life and consistently high density potential. Kanthal is the only wire that exudes alumina. It was designed for this.

After sampling many rebuilt and factory coils nothing I've seen few come close to a Kanthal wind precisely dialed in to your own personal density and heat target. My main goal is to make sure vapers have a tool in hand to simply and neatly get it. Like I've said, a signpost at the crossroads they can always rely upon and get back to.

Me I've very happy living at that intersection most of the time.

Good luck.

Don't understand what breaks this function but it doesn't uniformly when selecting text from alternate threads (tabs, alt windows)

Okay.. it works.. but.. I will explain elsewhere since this is off topic.

What is the difference between the coil I make with the coil master and a tensioned micro coil?

What is the difference between the coil I make with the coil master and a tensioned micro coil?

Two ways to shape wire. The first, forming which is to say basically to bend it. The second way is using strain or elongation, stretching.

When you strain wire you begin to alter and reorder its crystalline structure adding rigidity which is why contact coils better retain their precise orientation. Formed wire, even when wound on a known diameter spread and expand when the minimal tension applied by a coiler is released. This doesn't happen with a tensioned wind once you reach the strain or elongation point. The energy imparted to the wire is internalized.

For purposes of oxidation or extruding its alumina content having the wire in as closest and persistent contact as possible helps to ensure adequate and uniform oxidation. Alumina oxidation is thermally conductive but electrically resistive. Ideal to insulate adjacent turns to limit wire-to wire overheating. So the process of tensioning to contact and the resulting oxidation provides a very stable resistance under load (no hot segments in operation). Another way to look at this is as uniform thermal output which is the ideal we seek for maximal performance.

Best of all is that although there is some loss of rigidity using pulse oxidation of the tensioned coil enough is retained that the wind remains coherent far longer than a conventional non-strained wind.

This method results in a typical 25% gain in vaporization rate or vapor output as reported anecdotally by better than 90% of users or testers I surveyed over 3 years and my own participation with many users here in S FL. It's better than that but I lack the lab environment necessary to precisely quantify it for typical winds.

How is this useful? You can build a precise repeatable baseline wind. Any gauge, any resistance. Used wisely you can use the technique to maximize the wetted contact surface. Then optimize wicking or flow for that greater output. Now you're talkin'. Efficiency…at any power level and res you target. And you wound it in 30 seconds or less. Sweet.

Let me know sparks if any questions or doubts. I had more than a few myself.

Best of luck.

I have more questions but it’s late, so I will post in the morning.Two ways to shape wire. The first, forming which is to say basically to bend it. The second way is using strain or elongation, stretching.

When you strain wire you begin to alter and reorder its crystalline structure adding rigidity which is why contact coils better retain their precise orientation. Formed wire, even when wound on a known diameter spread and expand when the minimal tension applied by a coiler is released. This doesn't happen with a tensioned wind once you reach the strain or elongation point. The energy imparted to the wire is internalized.

For purposes of oxidation or extruding its alumina content having the wire in as closest and persistent contact as possible helps to ensure adequate and uniform oxidation. Alumina oxidation is thermally conductive but electrically resistive. Ideal to insulate adjacent turns to limit wire-to wire overheating. So the process of tensioning to contact and the resulting oxidation provides a very stable resistance under load (no hot segments in operation). Another way to look at this is as uniform thermal output which is the ideal we seek for maximal performance.

Best of all is that although there is some loss of rigidity using pulse oxidation of the tensioned coil enough is retained that the wind remains coherent far longer than a conventional non-strained wind.

This method results in a typical 25% gain in vaporization rate or vapor output as reported anecdotally by better than 90% of users or testers I surveyed over 3 years and my own participation with many users here in S FL. It's better than that but I lack the lab environment necessary to precisely quantify it for typical winds.

How is this useful? You can build a precise repeatable baseline wind. Any gauge, any resistance. Used wisely you can use the technique to maximize the wetted contact surface. Then optimize wicking or flow for that greater output. Now you're talkin'. Efficiency…at any power level and res you target. And you wound it in 30 seconds or less. Sweet.

Let me know sparks if any questions or doubts. I had more than a few myself.

Best of luck.

I have more questions but it’s late, so I will post in the morning.

Happy to help any way I can. Really love to get peeps to the point I describe. Most pass it on and that's what I'm lookin' for.

Good luck.

Been seeing much talk about not using factory coils on a mech lately. Did I miss something in ecf's history about exploding mechs from using them?

I'd like to place my Nautilus tank on my GP Paps someday....

Bad coils don't lead to exploding mech.... Bad BATTERIES cause exploding mods......

Shorted coils lead to burned out coils.. not vented batteties.

Sent from my SCH-I605 using Tapatalk

Ok, thank you for the information. I was not aware. I was under the impression from reading and research that stock coils on a mech mod was a big no no. Always learning I guess.

If a badly wound asymmetrical coil is going to arc, across itself or to the coil housing, it's going to happen regardless of the power source, mech or variable.

Building a repeatable, consistent baseline practically eliminates that concern. So it won't be happening with one of these…

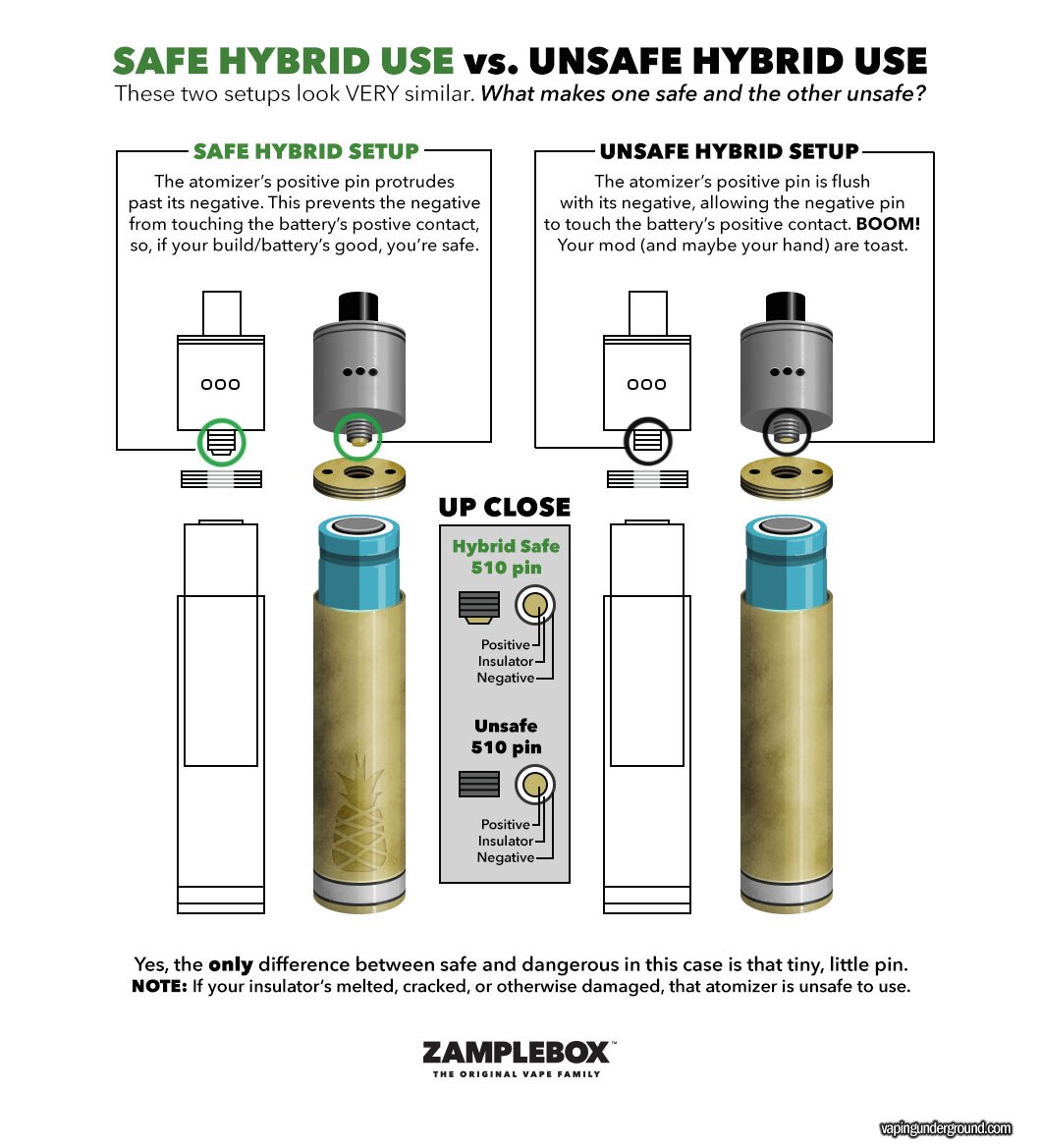

The remaining real concern with atomizers on mechanicals is the 510 connection. That the positive pin be adequately protruding such that it and the (negative) threads don't both simultaneously contact the battery positive causing a short. The positive pin on some atomizers is floating. That means that they can slide up too high into the 510 when screwed on too tightly. Great graphic illustration of this below thanks to the folks at Zamplebox®…

No worries. Vape safe.

The positive pin on some atomizers is floating. That means that they can shift up into the 510 if it is screwed on too tightly.

Good luck.

From the thread Good morning everybody . I'm new and researching ,first mech / build...... | Port # 100 | Page 5 | E-Cigarette Forum for reference…

Congrats. As you consider the differences, pay close attention to apparent temperature. Temperature at a given wattage or voltage is a clear indicator of the vaporization efficiency of a wind. That is, how effectively it accomplishes the conversion. It's not merely important how much volume you may seemingly generate which determines a real overall level of production but its density. A cooler deeper density at any level of power is evidence of success in capturing the high side limits of a wind's capacity of conversion.

One can always scale up a build to support more wattage (and so production) or add wattage to create more diffusion but you must have production first or you're merely further thinning the vape.

Comparisons to be accurate and pertinent need to be of wire or combinations of the same total mass.

[Sorry for the late edit. Still having my a.m. coffee, lol.]

Good luck.

I've been rollin these coils - and used both spaced and no…to see and taste myself if there is a difference, and if there, how big it is. From what i read , I expect some difference.

Congrats. As you consider the differences, pay close attention to apparent temperature. Temperature at a given wattage or voltage is a clear indicator of the vaporization efficiency of a wind. That is, how effectively it accomplishes the conversion. It's not merely important how much volume you may seemingly generate which determines a real overall level of production but its density. A cooler deeper density at any level of power is evidence of success in capturing the high side limits of a wind's capacity of conversion.

One can always scale up a build to support more wattage (and so production) or add wattage to create more diffusion but you must have production first or you're merely further thinning the vape.

Comparisons to be accurate and pertinent need to be of wire or combinations of the same total mass.

[Sorry for the late edit. Still having my a.m. coffee, lol.]

Good luck.

@MacTechVpr, HELP! (Please; and thank you!!)

The more I read, watch (super_X vids), and try; the worse my results become (regarding tension-coils).

Tonight, I tried going back to basics and resulted in the following:

I used kanthol A1 29ga. wire and wrapped around a (2.5mm-3.0mm machine screw <threaded rod actually... to give me a bit more grip>)

To create tension; I made 2 loose wraps of the wire on one end of the threaded rod (the other end of the wire is still attached to the spool), and clamped it in a small (6"?) pair of vise grips... trapping both wire and threaded rod.

Then I took a couple of additional wraps (to move the wind away from the vise grips).

Then, drawing the wire spool tight, I did my best to keep a significant amount of tension (I had previously done several trials to the point of breaking the wire), as well as a bit of back angle (against the direction/"pitch" of the screw/wind; to aid in the wire following the threads of the threaded rod), and ended up with an eight wrap coil (without any signs of "relaxing" or unwinding).

(Specific Steam Engine results say this should be between 1.8, and 1.9 ohms resistances; based on wire gauge, coil I.D., and "leg" length variables.)

I gauged the resulting I.D. as looser than my 2mm smooth bit, and tighter than my 2.5mm smooth bit. The initial resistance was about 1.8mm (based on the build; attached to the end build deck).

Then, with every pulse to the coil, the resistance raised 0.1-0.2 ohms per pulse. Ir was only when I reached 4.4 ohms that I chickened out.

I moved the build deck to a second mod; and it has set at a steady 1.88 ohm resistance.

WHAT IS GOING ON?

I repeatedly checked contact screws (to the wire/coil ends) to make sure they were tight (BEFORE switching over).

The original power supply is a old-school Sigielei 100W (series oriented 2 18650 battery) (non-temp control) box mod.

The secondary box mod is a Eleaf iStick100TC parallel-battery mod.

When I first dry-burned/pulsed the coil (prior to wicking) (at 10 watts) I got a uniform glow across the coil. No "inward-out" glow, like I have seen with previous contact coils.

I repeatedly checked the screw contacts, as well as short potentials, and had NO interference/change (to the increase OR overall resistance).

Is this a simple issue of the Sigielei being a P.O.S./worn out/contacts shot; or am I completely missing something????

Is it possible/likely... that a person is able to nick/scratch/ or otherwise, blemish the wire (I am fairly certain that I significantly scraped the coil wire against the thread peaks... WITHOUT necessarily providing noticeable damage (breaks/ "hangnails"/ or weakening to the point of it breaking)?

Additional note: I did not once touch the coil, or coil contact screws, after changing power supply... (to try to tighten, clear<clean>, or realign).

I am at the point that is is fully (re: ME) operator error; I am only hoping to find out what I am messing up...

Why the steady climb?

Why did it disappear when I changed the power supply?

Help please... ????

I am NOT "tension-savvy." I only seem to make two steps forward... to make one and a half steps back.

I thought, when I had the "even-glow" of the dry coil; I had arrived on the tensioned coil. I seemingly have much more to learn.

I am really starting to feel MORE ignorant than when I first began this endeavor.

The more I read, watch (super_X vids), and try; the worse my results become (regarding tension-coils).

Tonight, I tried going back to basics and resulted in the following:

I used kanthol A1 29ga. wire and wrapped around a (2.5mm-3.0mm machine screw <threaded rod actually... to give me a bit more grip>)

To create tension; I made 2 loose wraps of the wire on one end of the threaded rod (the other end of the wire is still attached to the spool), and clamped it in a small (6"?) pair of vise grips... trapping both wire and threaded rod.

Then I took a couple of additional wraps (to move the wind away from the vise grips).

Then, drawing the wire spool tight, I did my best to keep a significant amount of tension (I had previously done several trials to the point of breaking the wire), as well as a bit of back angle (against the direction/"pitch" of the screw/wind; to aid in the wire following the threads of the threaded rod), and ended up with an eight wrap coil (without any signs of "relaxing" or unwinding).

(Specific Steam Engine results say this should be between 1.8, and 1.9 ohms resistances; based on wire gauge, coil I.D., and "leg" length variables.)

I gauged the resulting I.D. as looser than my 2mm smooth bit, and tighter than my 2.5mm smooth bit. The initial resistance was about 1.8mm (based on the build; attached to the end build deck).

Then, with every pulse to the coil, the resistance raised 0.1-0.2 ohms per pulse. Ir was only when I reached 4.4 ohms that I chickened out.

I moved the build deck to a second mod; and it has set at a steady 1.88 ohm resistance.

WHAT IS GOING ON?

I repeatedly checked contact screws (to the wire/coil ends) to make sure they were tight (BEFORE switching over).

The original power supply is a old-school Sigielei 100W (series oriented 2 18650 battery) (non-temp control) box mod.

The secondary box mod is a Eleaf iStick100TC parallel-battery mod.

When I first dry-burned/pulsed the coil (prior to wicking) (at 10 watts) I got a uniform glow across the coil. No "inward-out" glow, like I have seen with previous contact coils.

I repeatedly checked the screw contacts, as well as short potentials, and had NO interference/change (to the increase OR overall resistance).

Is this a simple issue of the Sigielei being a P.O.S./worn out/contacts shot; or am I completely missing something????

Is it possible/likely... that a person is able to nick/scratch/ or otherwise, blemish the wire (I am fairly certain that I significantly scraped the coil wire against the thread peaks... WITHOUT necessarily providing noticeable damage (breaks/ "hangnails"/ or weakening to the point of it breaking)?

Additional note: I did not once touch the coil, or coil contact screws, after changing power supply... (to try to tighten, clear<clean>, or realign).

I am at the point that is is fully (re: ME) operator error; I am only hoping to find out what I am messing up...

Why the steady climb?

Why did it disappear when I changed the power supply?

Help please... ????

I am NOT "tension-savvy." I only seem to make two steps forward... to make one and a half steps back.

I thought, when I had the "even-glow" of the dry coil; I had arrived on the tensioned coil. I seemingly have much more to learn.

I am really starting to feel MORE ignorant than when I first began this endeavor.

ID, kinda at a loss whether you're making a contact m.c. or screw wind. Yes, I've seen countless times the res shoot up while pulsing before oxidation soundly sets in. Don't totally understand the physics but arcing via oxidation and wire width aberrations (gaps) is likely happening. This sends the wire res up and that's what you see before the wire totally cools down. Set it aside, maybe reinsert the bit (I don't rake) and it should read the rated res. At times if wire gets too heated this can distort the symmetry and result in loss of full contact. That's what raking in a way addresses. I prefer to carefully nudge the coil from either end and let the t.m.c. find its own shape (return to being the wound coil). Or, reinsert the bit particularly to match end-turn strain to the rest of the wind (often the problem, but don't over tighten). So that's what you check/do if you see those res distortions while pulsing to oxidation…along with light careful tweezing of the wind to help resolve any gray or dark spots caused by gaps.

But now, if you're winding on a screw a spaced coil, and you're still seeing odd res returns; then, you're looking at some other hardware or contact issue. I'd check it on an alt device or meter.

I wind tensioned spaced coils on screws and there seems to be a slight advantage in oxidation time/effort/pulses to achieve uniformity. Start coherent, end coherent. Even as it's a bad/loose/less then optimal connect that induces hot turns or leads, the flow goes to the highest res point, i.e. highest strain. That's what tension winding's about…balancing it all out.

Which leads me to strain level. I've always suggested folks start winding using an ordinary bit and pin vise for a reason. It's a lot easier with a light or medium gauge, say 32-29 AWG to learn where adhesion lives (closest contact). It's only a bit beyond there that you need to go. It's a narrow but identifiable zone of happiness. But if you push it which is easier to do with a jig you can excessively elongate the wire which may substantially increase resistance and give you a much warmer and even hotter result with thinner gauges.

No pin vice, grab a 7/64" (2.778mm) instrument screwdriver or other known diameter. It's very important as you've noticed to know what the res should be. It will definitely impact the thermal output and often quite noticeably if you fall short or over-run the zone.

Then ID just do a test with a couple of winds starting from the point that the wire is merely bent around the bit and slowly adding the same strain with each 1/4 to a 3rd rotation of the bit. If you ease off to improve the hand-hold on the PV try to always recall or return to the exact pressure you were applying. The gradual effort will help you see the precise point that adhesion begins as the turns stack up together…and stay that way!

Jig or pin vise or one-end-trapped vs. off-off-the spool, they all can work but the degree of strain being applied must be identified and learned to recognition and muscle memory. Once there, you will often find your winds requiring very few pulses even on thick gauges to begin oxidizing uniformly. You can continue the effort if you want to build further rigidity and capacity.

Strained spaced coils will have a tendency to fire more evenly end-to-end but not nearly what you see above (3 frames/sec) time lapse. If you want this, you'll need the smooth bit.

Not an answer ID but a starting point. Think we can narrow down your issue with some feedback.

Good luck.

But now, if you're winding on a screw a spaced coil, and you're still seeing odd res returns; then, you're looking at some other hardware or contact issue. I'd check it on an alt device or meter.

I wind tensioned spaced coils on screws and there seems to be a slight advantage in oxidation time/effort/pulses to achieve uniformity. Start coherent, end coherent. Even as it's a bad/loose/less then optimal connect that induces hot turns or leads, the flow goes to the highest res point, i.e. highest strain. That's what tension winding's about…balancing it all out.

Which leads me to strain level. I've always suggested folks start winding using an ordinary bit and pin vise for a reason. It's a lot easier with a light or medium gauge, say 32-29 AWG to learn where adhesion lives (closest contact). It's only a bit beyond there that you need to go. It's a narrow but identifiable zone of happiness. But if you push it which is easier to do with a jig you can excessively elongate the wire which may substantially increase resistance and give you a much warmer and even hotter result with thinner gauges.

No pin vice, grab a 7/64" (2.778mm) instrument screwdriver or other known diameter. It's very important as you've noticed to know what the res should be. It will definitely impact the thermal output and often quite noticeably if you fall short or over-run the zone.

Then ID just do a test with a couple of winds starting from the point that the wire is merely bent around the bit and slowly adding the same strain with each 1/4 to a 3rd rotation of the bit. If you ease off to improve the hand-hold on the PV try to always recall or return to the exact pressure you were applying. The gradual effort will help you see the precise point that adhesion begins as the turns stack up together…and stay that way!

Jig or pin vise or one-end-trapped vs. off-off-the spool, they all can work but the degree of strain being applied must be identified and learned to recognition and muscle memory. Once there, you will often find your winds requiring very few pulses even on thick gauges to begin oxidizing uniformly. You can continue the effort if you want to build further rigidity and capacity.

Strained spaced coils will have a tendency to fire more evenly end-to-end but not nearly what you see above (3 frames/sec) time lapse. If you want this, you'll need the smooth bit.

Not an answer ID but a starting point. Think we can narrow down your issue with some feedback.

Good luck.

Sorry for the confusion. My effort was directed to making a spaced tension coil. I used about a 1½ inch piece of threaded rod; which looks to be about the size of a 2mm machine screw.ID, kinda at a loss whether you're making a contact m.c. or screw wind.

As I mention in the previous post, as soon as I moved the atomizer deck (with the questionable coil still installed) to a second (different) devise, it behaved just fine. I immediately, and consistently (now for more than 24 hours), have and still read a steady 1.88 ohms (which is right were Steam Engine says it should be).But now, if you're winding on a screw a spaced coil, and you're still seeing odd res returns; then, you're looking at some other hardware or contact issue. I'd check it on an alt device or meter.

I don't know if it was due to the oxidation stabilizing; as I totally forgot about that part, and failed to observe it. Or, if it was just that the original devise is finally giving out.

Actually, aside from the squirrelly initial resistance reading, that is very similar to they way this coil performed. The glow/color was almost immediate, and happened uniformly across the entire coil (vs. starting in the middle and working out to the ends). No hot spots or hot leges were ever noticed.Strained spaced coils will have a tendency to fire more evenly end-to-end but not nearly what you see above (3 frames/sec) time lapse. If you want this, you'll need the smooth bit.

I hope the above helps. If I am still leaving needed information out, just ask, and I will do my best to answer.Not an answer ID but a starting point. Think we can narrow down your issue with some feedback.

Thanks Mac; for your time, patience, AND willingness to help out those of us who are "challenged." Your assistance is greatly appreciated!Good luck.

Regarding screw winds…

Good explanation @IDJoel. It helps. Yes, as I said, coils can go hot (higher res) during pulsing to oxidize. But it does sound like you actually made a nice balanced coil there (on a screw, recommended for spacers, or things get unpredictable).

In all likelihood you wound tightly and there was some imbalance in your installation somewhere. Things got hot until oxidation progressed. Sounds like. But yes, balanced strain helps get uniform output for any wind…if indeed it is balanced.

Your scenario points to another issue. How do you tell how tight you're winding with a screw? Learning to do tensioned contacts you rely upon eyesight to fix the point that adhesion occurs. And like I said, a bit beyond that to ensure the coil's rigid enough to not come undone (expand, as with coilers, springy) when you let off the pressure. My take, as I make them both, is that you end up adding a little bit more strain than needed. So they run (or have to be run) a tad warmer than a well optimized t.m.c.

As you noted with this problem an inexact i.d. is like a loose canary. Does you no good down that dark mine when the res goes off. So the problem with screws is you lose the advantage of being able to predict the wire length (res) as you plan your build. It's hard to know what the exact landing point or pitch diameter within the threads of the screw channel (where the wire sits within the thread)…unless you want to do some math. If the inner diameter of the wind varies there goes repeatability.

The diagrams and inputs here may help…

UN imperial screw thread calculator

Fastener / Thread Pitch Circle Calculator | Engineers Edge | www.engineersedge.com

Fastener Thread Pitch Circle Diameter Equation and Calculator | Engineers Edge

If you have similar you'd like to share, let me know. Never enough tools.

Best of luck and keep us posted!

Good explanation @IDJoel. It helps. Yes, as I said, coils can go hot (higher res) during pulsing to oxidize. But it does sound like you actually made a nice balanced coil there (on a screw, recommended for spacers, or things get unpredictable).

In all likelihood you wound tightly and there was some imbalance in your installation somewhere. Things got hot until oxidation progressed. Sounds like. But yes, balanced strain helps get uniform output for any wind…if indeed it is balanced.

Your scenario points to another issue. How do you tell how tight you're winding with a screw? Learning to do tensioned contacts you rely upon eyesight to fix the point that adhesion occurs. And like I said, a bit beyond that to ensure the coil's rigid enough to not come undone (expand, as with coilers, springy) when you let off the pressure. My take, as I make them both, is that you end up adding a little bit more strain than needed. So they run (or have to be run) a tad warmer than a well optimized t.m.c.

As you noted with this problem an inexact i.d. is like a loose canary. Does you no good down that dark mine when the res goes off. So the problem with screws is you lose the advantage of being able to predict the wire length (res) as you plan your build. It's hard to know what the exact landing point or pitch diameter within the threads of the screw channel (where the wire sits within the thread)…unless you want to do some math. If the inner diameter of the wind varies there goes repeatability.

The diagrams and inputs here may help…

UN imperial screw thread calculator

Fastener / Thread Pitch Circle Calculator | Engineers Edge | www.engineersedge.com

Fastener Thread Pitch Circle Diameter Equation and Calculator | Engineers Edge

If you have similar you'd like to share, let me know. Never enough tools.

Best of luck and keep us posted!

Last edited:

Lifted from the thread Best wicking matetial | Page 4 | Post #77 | E-Cigarette Forum for reference here.

Regarding wicking and management of any flaking when sectioning Nextel, see these two posts…

Best wicking matetial | Page 4 | Post #80 | E-Cigarette Forum

Best wicking matetial | Page 4 | Post # 75 | E-Cigarette Forum

CMD we both know this stuff is incredibly easy to wick. And if you know how it takes seconds and there is little shedding when properly handled.

But get this…if you use a fine needle nose tweezers you can insert the moist wick almost through any wind. Even a monster like this one…

You just moisten the point and squeeze or slightly roll the tip tightly as you grip it with the tweezer point. Since the wick being braided and hollow compresses you can use this technique to insert 3mm into all diameters above 7/64" (2.778mm). Once in it's so slippery that it follows the wind right through if you just softly rotate it with a little forward pressure.

It's almost as much a pleasure rebuilding with this as using it.

Good luck.

Regarding wicking and management of any flaking when sectioning Nextel, see these two posts…

Best wicking matetial | Page 4 | Post #80 | E-Cigarette Forum

Best wicking matetial | Page 4 | Post # 75 | E-Cigarette Forum

@MacTechVpr knows more than I, I defer to him above. I do use the VG, kind of wipe the ends down while shaping the wick before I try (with varying success) to get it in the coil.

CMD we both know this stuff is incredibly easy to wick. And if you know how it takes seconds and there is little shedding when properly handled.

But get this…if you use a fine needle nose tweezers you can insert the moist wick almost through any wind. Even a monster like this one…

You just moisten the point and squeeze or slightly roll the tip tightly as you grip it with the tweezer point. Since the wick being braided and hollow compresses you can use this technique to insert 3mm into all diameters above 7/64" (2.778mm). Once in it's so slippery that it follows the wind right through if you just softly rotate it with a little forward pressure.

It's almost as much a pleasure rebuilding with this as using it.

Good luck.

For general info here, from the thread …Vaping is too complicated. | Page 4 | Post #79 | E-Cigarette Forum…

The foremost cause of hot leads or hot segments in open or closed coils is geometric asymmetry. This may as well contribute to ineffective termination. The mangling brought by the irregularity of hand winding or common forming (bending) can corrupt a wind and unbalance dual or parallel elements. A common hazard is inconsistent wick contact which results in hot zones or segments regardless of coil type, i.e. variations in turn-to-turn diameters, spacing. There is a methodology to best promote temp stability across coils using strain in wind and installation to promote symmetry, uniform rigidity, oxidation and so durability. It makes best use of the properties of Kanthal, a wire developed to serve as a thermal element. Such coils are notably less susceptible to hot leads. Best of all, it's so simple anyone can do it…and consistently reproduce it!

It may not be the way we always vape…but it sure is a nice warm and reliable hearth to return to from the cold.

Good luck all and Happy New Year.

The foremost cause of hot leads or hot segments in open or closed coils is geometric asymmetry. This may as well contribute to ineffective termination. The mangling brought by the irregularity of hand winding or common forming (bending) can corrupt a wind and unbalance dual or parallel elements. A common hazard is inconsistent wick contact which results in hot zones or segments regardless of coil type, i.e. variations in turn-to-turn diameters, spacing. There is a methodology to best promote temp stability across coils using strain in wind and installation to promote symmetry, uniform rigidity, oxidation and so durability. It makes best use of the properties of Kanthal, a wire developed to serve as a thermal element. Such coils are notably less susceptible to hot leads. Best of all, it's so simple anyone can do it…and consistently reproduce it!

It may not be the way we always vape…but it sure is a nice warm and reliable hearth to return to from the cold.

Good luck all and Happy New Year.

@MacTechVpr Would you care to give our friend Randy a brief lesson and some links?

Not to sure Randy's on board with the mission there Leti.

What I will say is that I spent many months proofing the principle with extraordinary amounts of hands on by myself and others. Discussed the issue and process for many moons with both supe who introduced the closed (contact) coil and physicist Bill who designed the first mech jig to make them. As well with physicist Boden who confirms the potentials of concentration if not uniform oxidation with his own designs. So I'm quite confident in the physics and what they mean for the average and every vaper. And he list could get much bigger particularly if I were to include external references.

Suffice it to say I know the number of users is substantial even if they seldom ack or recall the source of the contribution. In great measure this has been my wish that at as many vapers as possible acquire the simple means to precisely build stable wind baselines. That's my mission. Always glad to help…

Good luck.

Lifted from the thread FL ALERT: Florida Constitution Revision Commission | E-Cigarette Forum for reference here…

Just received an alert from Alex Clark, CEO (CASAA), re Proposal 65…which ostensibly proposes a referendum amending the FL constitution to proscribe public [indoor] vaping, to be placed on the ballot in Nov. This is horribly short notice for this apparently first public meeting of the Constitutional Revision Commission (CRC) on this issue. For this critical question with profound individual rights implications, participants will only be allowed 2 minutes to voice their opinion!

For what it's worth, here at the particulars…

Tuesday, February 6, 2018

1:00 PM - 7:00 PM

Rick Case Arena at the Don Taft University Center (map)

3301 College Avenue

Fort Lauderdale, FL 33314

Presently because the state preempts legislation on this matter private business and those who live in community environments are somewhat sheltered from frivolous local regulation. If this passes a great many vapers and vape enterprise owners may find themselves targeted by every street corner zealot.

Good luck.

Just received an alert from Alex Clark, CEO (CASAA), re Proposal 65…which ostensibly proposes a referendum amending the FL constitution to proscribe public [indoor] vaping, to be placed on the ballot in Nov. This is horribly short notice for this apparently first public meeting of the Constitutional Revision Commission (CRC) on this issue. For this critical question with profound individual rights implications, participants will only be allowed 2 minutes to voice their opinion!

For what it's worth, here at the particulars…

Tuesday, February 6, 2018

1:00 PM - 7:00 PM

Rick Case Arena at the Don Taft University Center (map)

3301 College Avenue

Fort Lauderdale, FL 33314

Presently because the state preempts legislation on this matter private business and those who live in community environments are somewhat sheltered from frivolous local regulation. If this passes a great many vapers and vape enterprise owners may find themselves targeted by every street corner zealot.

Good luck.

Last edited:

Lifted from the thread Coils caught on fire! | Page 2 | E-Cigarette Forum for reference…

Massively agree with your 1st P. But there's nary a discussion of the shorting potentials of asymmetrical unoxidized multi-wire no matter how much we rake, chant or good the soundtrack…

OP's post adequately describes arcing. Note to self (it doesn't have to touch). Oh, and they can run the length of the coil, no screwdriver required.

Not everything beautiful works as advertised.

Good luck.

[p.s. Upping the power (voltage) increases those potentials.]

This.

I use the same mod, rarely go below .2 in my single coils. The vape is smooth and watm enough and the battery doesn't take a killing.

I agree with the others, looks like the coil is touching something. May have moved it while wicking.

Massively agree with your 1st P. But there's nary a discussion of the shorting potentials of asymmetrical unoxidized multi-wire no matter how much we rake, chant or good the soundtrack…

OP's post adequately describes arcing. Note to self (it doesn't have to touch). Oh, and they can run the length of the coil, no screwdriver required.

Not everything beautiful works as advertised.

Good luck.

[p.s. Upping the power (voltage) increases those potentials.]

I guess that was Supe V1, as Supe V2 vapes flavored juices, some regulated squonkers, and IIRC even premade coils from others.Discussed the issue and process for many moons with both supe

Love that guy.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 863

- Replies

- 0

- Views

- 726

- Replies

- 9

- Views

- 2K

- Replies

- 0

- Views

- 920

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)