Do keep in mind it will probably take double the time for the coil to heat up with that many wraps...

Yeah, I realize that. So is there an "Optimum" number of wraps? Is this why 8 wrap coils seem to be the norm.?

Do keep in mind it will probably take double the time for the coil to heat up with that many wraps...

Isn't the heatflux dropping a lot when you're not upping the power in this scenario?

That's good news ether. Keepin' tension and rotation up is hard for some of us. Thicker wire can make it a challenge. Trick is learning to detect the level of strain pulling the wire off the spool. Or, if you use a needle nose or such. Fingers are far more sensitive than the wrist.

If we really look at our coils, learn to distinguish the subtle differences in coil color temperature you will see exactly why your micro's not goin' full t.m.c. from the jump. It may be imperfections in the wire but often it's just a subtle variation in our wind. Imperfections are often cured with just the right level of strain. They'll show up in the set if tension's not consistent (inconsistent turn-to-turn pull). Not only does this make it tedious to square away but it may never operate at the best resistance. And you'll see the result in the smoothness of the vape.

Even if you're not using fat wire, if you're having problems with variation switching off to the gizmo can help.

Thx E.

Good luck.

Exactly Mac,

I've been playing with weight for a consistent benchmark of strain and teasing it a bit with my fingers for slight variation and so i can feel the tension applied by the weight. At this point I can almost duplicate it with vise grips on the end of the wire as an anchor.

Hope to be able to get it right soon.

Exactly Mac,

I've been playing with weight for a consistent benchmark of strain and teasing it a bit with my fingers for slight variation and so i can feel the tension applied by the weight. At this point I can almost duplicate it with vise grips on the end of the wire as an anchor.

Hope to be able to get it right soon.

My only modification to the coil gizmo, it makes setting the initial turn simple.

Today's challenge, parallels.

Oh thank God, I thought the internet was broken lol!Hmmmm... is that JB Weld or epoxy?

I just bent the handle inwards until the thumbscrew was directly under where my first turn usually starts, it also prevents the leg from angling outwards from that initial turn.

Check out RipTrippers video on YouTube about building the Subtank RBA deck.

I haven't seen the video yet, but damn fine comparison Mac. We need more critical analysis that we can use to compare build efficiency with that gives a common language.Hey M..., thanks for the post. Handn't seen it and was wondering what all the fuss was about.

A pretty hot coil without any oxidation insulation of the wire in an already very diffuse and quite warm tank design. Bears no resemblance in form, function, stability or flavor result to what I posted above.

But thanks, it's informative. He did a better job on his original OCC build. I would not recommend the above coil to a beginner vaper or rebuilder without expecting some frustration (as noted by a number of the posters).

A 28 gauge, 7-wrap on 3/32" will give ya 25% more surface area an a thicker wick (more flow, density potential) on a 3.44 amp draw (vs. 5.48 for a very atypically neat hand 5-wrap) for better battery service and vapor production. A tension wind on a screw driver or pin vise will yield this very predictable repeatable wind in under a minute. How many will duplicate Ripp's wind exactly and hit that 5.4Ω mark? Or even be able to calculate the wind spacing? We can do things the hard way of course if that's our preference.

It's correct to conclude that the Subtank is not a tank capable of providing a fuller vapor density. It can't. Not with the open wind designs in use until the microcoil two years ago. I vape extremely dense and complex juices particularly tobacco and have no issues reaching the density target I require. Definitely not difficult on as well engineered a tank as this, to Kanger's credit (for the exceptional airflow and tight fitment).

Not a criticism bro. A comparison. I'm struggling to see how this video benefits newcomers.

Good luck M.

Tension is the light and the way on the path to a heavenly vape folks... I am so sold on it!

Thanks to mac and drifter for this thread and their contributions to it!...Unfortunately the mass producing/marketing coil manufacturers would never go to a tensioned coil... they'd lose too much of their consumables profits! <--- Even though it would be the environmentally sane thing to do!

So I'm looking at building my own whatchamajigit and have a couple of questions..

I can get brass rods in the sizes I want relatively cheap.

Is brass good enough for the jig or should I look at copper or steel?

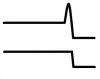

Is there a reason for bending the rod 90 degrees one direction and 180 back over the centerpoint before bending another 90 out for the handle?

Is this an overtension prevention concept?

A picture may describe it better..

View attachment 425447

Brass is too soft for the tension needed IMO. It will bend. You wanna use music wire - it's steel.

Brass breaks too easily, tried it, I do use it as s matching size mandrel in my travel rebuild kit though.So I'm looking at building my own whatchamajigit and have a couple of questions..

I can get brass rods in the sizes I want relatively cheap.

Is brass good enough for the jig or should I look at copper or steel?

Is there a reason for bending the rod 90 degrees one direction and 180 back over the centerpoint before bending another 90 out for the handle?

Is this an overtension prevention concept?

A picture may describe it better..

View attachment 425447