Magnesium oxide is not what I was expecting at all.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

75W Vaporesso TARGET 2 VTC Kit with Ceramic cCELL Coil

- Thread starter 100%VG

- Start date

- th_trl_thread_readers 0

-

- Tags

- target 2 vtc vaporesso

- Status

- Not open for further replies.

I just noticed one thing, all the wires out there are some kind of metal, they are all oxidized during the heating process, and we are worrying about the close to 0.0XX% magnesium oxide in the ceramic? seriously?Magnesium oxide is not what I was expecting at all.

Yeah when I google magnesium oxide fumes it linked me to a page on Wikipedia entitled metal fume fever where it stated that it was a condition experience primarily by welders working with galvanized or stainless steel. Weird man, just weird.I just noticed one thing, all the wires out there are some kind of metal, they are all oxidized during the heating process, and we are worrying about the close to 0.0XX% magnesium oxide in the ceramic? seriously?

Looks like this might be another case of using Industrial conditions (Manufacturing conditions in this case) to say that something is bad for a vape application.Yeah when I google magnesium oxide fumes it linked me to a page on Wikipedia entitled metal fume fever where it stated that it was a condition experience primarily by welders working with galvanized or stainless steel. Weird man, just weird.

.

Vaporesso is defending their coils. Here's a statement from them on their website:

STATEMENT

This seems pretty drastic. The vendor could be releasing a competing product...but if so, I doubt they would lie about this, as it would muddy the water for their own product too. If this turns out to be true, I know I'll stay far away from these type of coils for a long while.

My bet now is- said vendor wanted to release a ceramic coil product and thought "hmm, we better test first to see" and then found this out. That would explain the motivation for doing so. Of course, I'm just speculating.

This seems pretty drastic. The vendor could be releasing a competing product...but if so, I doubt they would lie about this, as it would muddy the water for their own product too. If this turns out to be true, I know I'll stay far away from these type of coils for a long while.

My bet now is- said vendor wanted to release a ceramic coil product and thought "hmm, we better test first to see" and then found this out. That would explain the motivation for doing so. Of course, I'm just speculating.

I am leaning toward believing that Vaporesso has thoroughly tested this tech before releasing it, but of course I will follow all of this closely. It will be nice to have a definitive answer (sounds like next week for the other independent test) but I can't see Vaporesso's legal department releasing this statement without having the data to back it up. I really do hope this turns out to be nothing. I would be really sad if I had to stop using these coils!!

Regardless of the outcome it seems unfair that the ones actually making the accusations are still cloaked in anonymity. Hard to defend yourself against a shadow....

Statement from Vaporesso Via Phil

http://www.tasteyourjuice.com/wordpress/archives/10002

Smoore? This is interesting. So it's Smoore e-cig that is the manufacturer; Vaporesso is the name of the product line. I thought that Vaporesso was a new manufacturer. Smoore has been around for awhile, making cigalikes, mostly. Not very popular in the States.

FWIW, I decided not to use those coils for two reasons.

1) I don't want to inhale anything that has traveled through a layer a porous ceramic, period. I've learned enough about different kinds of silica/ceramic/fiberglass etc. during the Aspire debacle to know that I don't want to use it. Yes, I've heard the argument that the sintered ceramic is stable (not crumbly like that "ceramic paper" used by Aspire) if no force is applied to it, but honestly, forcing eliquid through a layer of hot ceramic is applying force, in my book, even though it may not be the same kind of force as hitting it with a hammer. But there is force involved, and that force is being applied repeatedly with every inhalation. I haven't seen any tests showing that no minuscule particles of fiberglass/ceramic fiber are being dislodged and possibly mixed with the ejuice/vapor. AFAIK, the only kind of silica that is safe for inhalation is amorphous silica (silica rope used in traditional wicks) and not fiberglass or ceramic.

2) I don't want to use any wire, kanthal or nickel, that has been "dry burned" for prolonged time at 1,200 degrees Celsius.

That said, those are just my opinions on the subject and I'm not trying to tell anybody what to use or not use--I'm not a materials engineer so I don't have enough knowledge to do that. But I try to educate myself and follow the advice of better informed vapers whom I trust--like Dr. Farsalinos, for example.

The possible toxicity of those coils is an interesting development, if true, but not a game changer for me, as I have decided not to use them anyway.

But Venders don't release new products. They sell products. Manufacturers release new products.My bet now is- said vendor wanted to release a ceramic coil product and thought "hmm, we better test first to see" and then found this out. That would explain the motivation for doing so. Of course, I'm just speculating.

.

The MSDS Report only disclosed the individual elements in the ceramic. It used to show the percentages of each, but that part was redacted out the last time I looked. However, none of this addresses anything about the ceramic while in use, or after it has been used for any period of time. And the exact type of ceramic has not been stated, that I have seen. We are left to assume that it is an Aluminum Oxide.I am leaning toward believing that Vaporesso has thoroughly tested this tech before releasing it, but of course I will follow all of this closely. It will be nice to have a definitive answer (sounds like next week for the other independent test) but I can't see Vaporesso's legal department releasing this statement without having the data to back it up. I really do hope this turns out to be nothing. I would be really sad if I had to stop using these coils!!

The type of testing being done is what matters most. A crush test won't tell us anything about the ceramic under normal vaping conditions. I've seen it said that the cCells are also being studied for what is actually in the vapor. That would be the best approach, IMO.

The case has been made (at least here in threads on ECF) that the expanding and contracting of the wire (through heating and cooling) has a potential to degrade the ceramic around it, and that this could release particles into the vapor. But that testing has not been done so far on this particular ceramic coil. Said degradation may not be able to occur in the normal and proper use of a TC wire, though Dry Burning a Kanthal wire could. But it is stated in the manual that Dry Burning should not be done. And Dry Burning is not a normal vaping condition. It's a Cleaning situation, which is a procedure that is warned against doing in the manual. Studying what is actually in the vapor would either verify that something harmful is in it (and should state under what conditions to be perfectly clear and transparent), to what degree it is found, and state the level of danger (under various conditions if applicable), or it will put the whole thing to rest.

The grain size of the ceramic powder used to create the finished ceramic product. That same powder is what makes this ceramic more dense and hard (and less brittle) than the Clay ceramic, and may therefore make it harder to degrade via the coil's changes in temperature. I think that the only valid thing to be studied is what's in the vapor, not counting the elements of the juice... only what might come from the ceramic itself. But that's just my take on it.

.

Last edited:

The MSDS Report only disclosed the individual elements in the ceramic. It used to show the percentages of each, but that part was redacted out the last time I looked. However, none of this addresses anything about the ceramic while in use, or after it has been used for any period of time. And the exact type of ceramic has not been stated, that I have seen.

Exactly right.

The case has been made (at least here in threads on ECF) that the expanding and contracting of the wire (through heating and cooling) has a potential to degrade the ceramic around it, and that this could release particles into the vapor. But that testing has not been done so far on this particular ceramic coil..

Exactly.

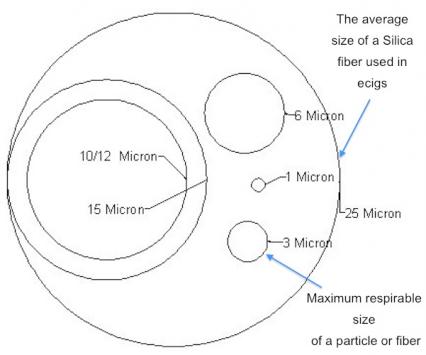

Personally, I don't think the argument of particles being washed through the ceramic are valid. For one, those particles would have to be in the juice. Second, the size any particles allowed to flow though the ceramic are limited to 12µm, because of the grain size of the ceramic powder used to create the finished ceramic product.

But those may be dangerous--if they are respirable. Anything under 5µm is definitely a no-no.

Please reread the posts I linked earlier in this thread, by Boden, explaining the difference between safe for inhalation amorphous silica vs. unsafe crystalline silica and ceramic fibers.

The "dangers" of silica wicks (post #70)

The "dangers" of silica wicks (post #71)

Last edited:

The MSDS Report only disclosed the individual elements in the ceramic. It used to show the percentages of each, but that part was redacted out the last time I looked. However, none of this addresses anything about the ceramic while in use, or after it has been used for any period of time. And the exact type of ceramic has not been stated, that I have seen. We are left to assume that it is an Aluminum Oxide.

The type of testing being done is what matters most. A crush test won't tell us anything about the ceramic under normal vaping conditions. I've seen it said that the cCells are also being studied for what is actually in the vapor. That would be the best approach, IMO.

The case has been made (at least here in threads on ECF) that the expanding and contracting of the wire (through heating and cooling) has a potential to degrade the ceramic around it, and that this could release particles into the vapor. But that testing has not been done so far on this particular ceramic coil. Said degradation may not be able to occur in the normal and proper use of a TC wire, though Dry Burning a Kanthal wire could. But it is stated in the manual that Dry Burning should not be done. And Dry Burning is not a normal vaping condition. It's a Cleaning situation, which is a procedure that is warned against doing in the manual. Studying what is actually in the vapor would either verify that something harmful is in it (and should state under what conditions to be perfectly clear and transparent), to what degree it is found, and state the level of danger (under various conditions if applicable), or it will put the whole thing to rest.

Personally, I don't think the argument of particles being washed through the ceramic are valid. For one, those particles would have to be in the juice. Second, the size any particles allowed to flow though the ceramic are limited to 12µm, because of the grain size of the ceramic powder used to create the finished ceramic product. That same powder is what makes this ceramic more dense and hard (and less brittle) than the Clay ceramic, and may therefore make it harder to degrade via the coil's changes in temperature. I think that the only valid thing to be studied is what's in the vapor, not counting the elements of the juice... only what might come from the ceramic itself. But that's just my take on it.

.

I totally agree that the vapor itself should be studied. If there is concern for toxicity, it will be delivered via the vapor and that's the information I want. Excellent write up, VG, as usual!

Thanks. I edited that part out.But those [12µm particles] may be dangerous--if they are respirable. Anything under 5µm is definitely a no-no.

.

Thanks. I edited that part out.

.

VG, I'm just thinking aloud here... I'm not sure of anything, really. I don't know for a fact what size particles are being used in those coils. I'm just not sure of anything at this point. But this illustration (thanks, Boden

Per Boden (and his sources), the maximum respirable size is 3µm--those can cause silicosis. Our standard wicks (silica rope) are 20-32µm--that's safe.

Anything in-between? I have no idea.

I appreciate that, but it doesn't matter with regard to the purpose of my statement, which was about the kind of testing that should be performed... testing of what is in the vapor. No matter what size particles may be in the vapor, if they are harmful, we need to know about it. For all we know, particles of ceramic larger than 12µm and/or particles that are 3µm or smaller could make their way into the vapor, especially if the wire causes degradation from heating and cooling. I don't know how this might relate to Magnesium Oxide, but anything harmful should be revealed, and I believe that testing the vapor properly should do just that.VG, I'm just thinking aloud here... I'm not sure of anything, really. I don't know for a fact what size particles are being used in those coils. I'm just not sure of anything at this point. But this illustration (thanks, Boden) is interesting.

Per Boden (and his sources), the maximum respirable size is 3µm--those can cause silicosis. Our standard wicks (silica rope) are 20-32µm--that's safe.

Anything in-between? I have no idea.

According to this chart, Magnesium Oxide (MgO) is found in both the cCell ceramic and the Clay ceramic from the Study. But I don't know why it should be released from vaping with ceramic. It's an integral part of the ceramic itself. The ceramic was created at Temperatures much higher than vaping.

.

Actually we may look at this thing wrong way, if we test the vapor come from any regular coil head in the market, I am pretty sure we will found all those components you mentioned, maybe more, because wire itself. when cotton burns, it generate particales as well, even bigger particales. The questions really here are, compared to a regular coil head, is it better or worse?I appreciate that, but it doesn't matter with regard to the purpose of my statement, which was about the kind of testing that should be performed... testing of what is in the vapor. No matter what size particles may be in the vapor, if they are harmful, we need to know about it. For all we know, particles of ceramic larger than 12µm and/or particles that are 3µm or smaller could make their way into the vapor, especially if the wire causes degradation from heating and cooling. I don't know how this might relate to Magnesium Oxide, but anything harmful should be revealed, and I believe that testing the vapor properly should do just that.

According to this chart, Magnesium Oxide (MgO) is found in both the cCell ceramic and the Clay ceramic from the Study. But I don't know why it should be released from vaping with ceramic. It's an integral part of the ceramic itself. The ceramic was created at Temperatures much higher than vaping.

.

The questions really here are, compared to a regular coil head, is it better or worse?

Well, other coils do not come with ceramic wicks, so there should not be any silica particles of any size in them.

Those other coils have been studied already, BTW, and nothing dangerous was found in the vapor; just tiny amounts of various metals, but in amounts similar or smaller than what was found in ambient air (USC study).

Here are all the data from the USC study, including Compounds, Outdoor air, e-Cigarette, and normal cigarette.http://www.rsc.org/suppdata/em/c4/c4em00415a/c4em00415a1.pdf

For your convenience, listed below are the amounts of Cr, Ni, Pb, Zn and Al in outdoor air vs e-cigarette vapor:

Cr: 5.53 vs 4.22

Ni: 5.57 vs 6.14 (+/-2.9)

Pb: 13.28 vs 9.85

Zn: 54.31 vs 56.08 (+/- 21 [sic])

Al: 333.27 (±62.93) vs 161.43 (±71.35)

So, vapor is actually healthier, per this study, than the air we breathe here in SoCal.

That's actually what I am talking about, 'just tiny amounts of various metals'. So more 0.0xx% metallic oxide in ceramic (compared to whole metal wire) will make any difference?Well, other coils do not come with ceramic wicks, so there should not be any silica particles of any size in them.

Those other coils have been studied already, BTW, and nothing dangerous was found in the vapor; amounts of various metals, but in amounts similar or smaller than what was found in ambient air (USC study).

Bed time guys, good night

I saw that study as well. I thought it was great. But Magnesium Oxide was stated as being the concern (or one of them), and MgO does not show up in the USC Study, so it would be an important finding in this case.Well, other coils do not come with ceramic wicks, so there should not be any silica particles of any size in them.

Those other coils have been studied already, BTW, and nothing dangerous was found in the vapor; just tiny amounts of various metals, but in amounts similar or smaller than what was found in ambient air (USC study).

Here are all the data from the USC study, including Compounds, Outdoor air, e-Cigarette, and normal cigarette.http://www.rsc.org/suppdata/em/c4/c4em00415a/c4em00415a1.pdf

For your convenience, listed below are the amounts of Cr, Ni, Pb, Zn and Al in outdoor air vs e-cigarette vapor:

Cr: 5.53 vs 4.22

Ni: 5.57 vs 6.14 (+/-2.9)

Pb: 13.28 vs 9.85

Zn: 54.31 vs 56.08 (+/- 21 [sic])

Al: 333.27 (±62.93) vs 161.43 (±71.35)

So, vapor is actually healthier, per this study, than the air we breathe here in SoCal.

.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 4K

- Locked

- Replies

- 2K

- Views

- 73K

- Replies

- 2K

- Views

- 67K

- Replies

- 0

- Views

- 4K

- Locked

- Replies

- 533

- Views

- 23K

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)