My apologies if someone else has come up with this idea. I haven't read all of this thread, but I thought of this last night.

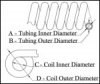

One tube inside another with a coil wrapped inside the inner surface of the inner tube. The inner tube is sealed at the top.

Either mesh or cotton to somehow coat the surface of the inner tube with juice. I'll leave that up to you.

The juice vaporizes off the hot surface of the inner tube.

Like juice being vaporized on the surface of a lightbulb.

The outside tube can be insulating to keep the heat where it's needed. Ceramic?

Problem is, where to enter the coil into the inner tube? And how to coil it inside? Perhaps the inner tube top could be unsealed and protrude above the outer tube with the coil dropped in.

Love Frisky Dingo by the way! Yeah the whole encapsulated coil has been discussed pretty thoroughly. New ideas are always considered-or at least I think they are. The discussion has fractured into three parts.

The original insulation "sleeve" idea-refer to page 1

The contained coil or "fuse" idea in which the wick surrounds the tubing/coil inside

3 chamber atty idea in which the vapor fills a seperate chamber.

I think thats the whole shabang-long read! But not as long as some of the innovating threads that some here have been a part of. My hats off to you guys! I'm still trying to wrap my head around software controlled e-cigs and I'm just glad I have a working prototype steaming away in my hands. The joystick looks cool on the Evic and it would give us the option to manually ramp up the volts to get our scuba-qs chain vaping and then take it down a notch and coast into a nice little session. Next on the horizon is a venturi bell drip tip

ps. There was also discussion of coated coils (enamel primarily)

Last edited: